Servo pump controlled hydraulic fine blanking machine and hydraulic machining method

A technology of servo pump and fine blanking machine, which is applied in the field of hydraulic processing of servo pump controlled hydraulic fine blanking machine, hydraulic fine blanking machine, and servo pump controlled hydraulic fine blanking machine. Leakage and other problems can be avoided to achieve the effect of avoiding interference, increasing the driving force uniformly, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

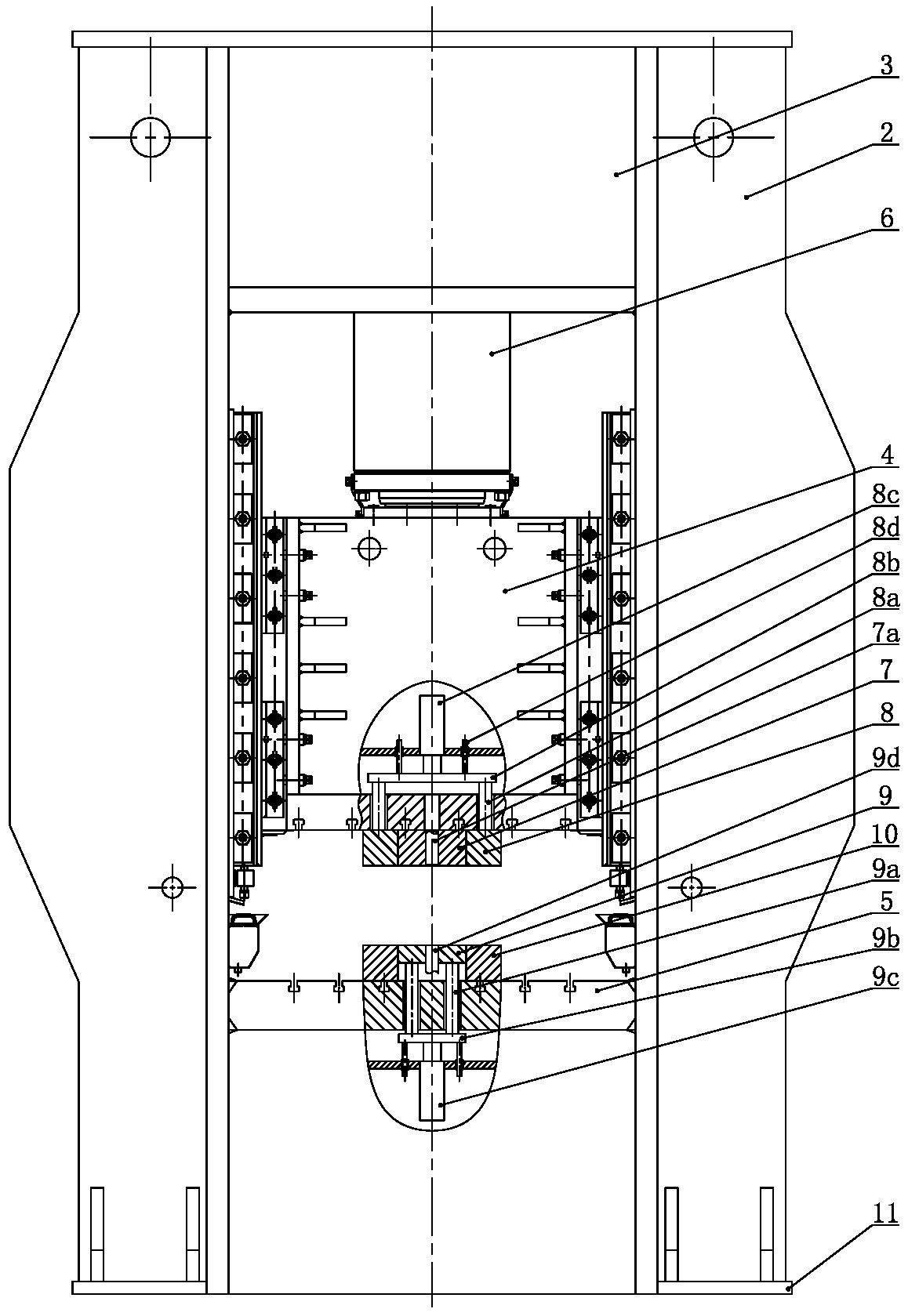

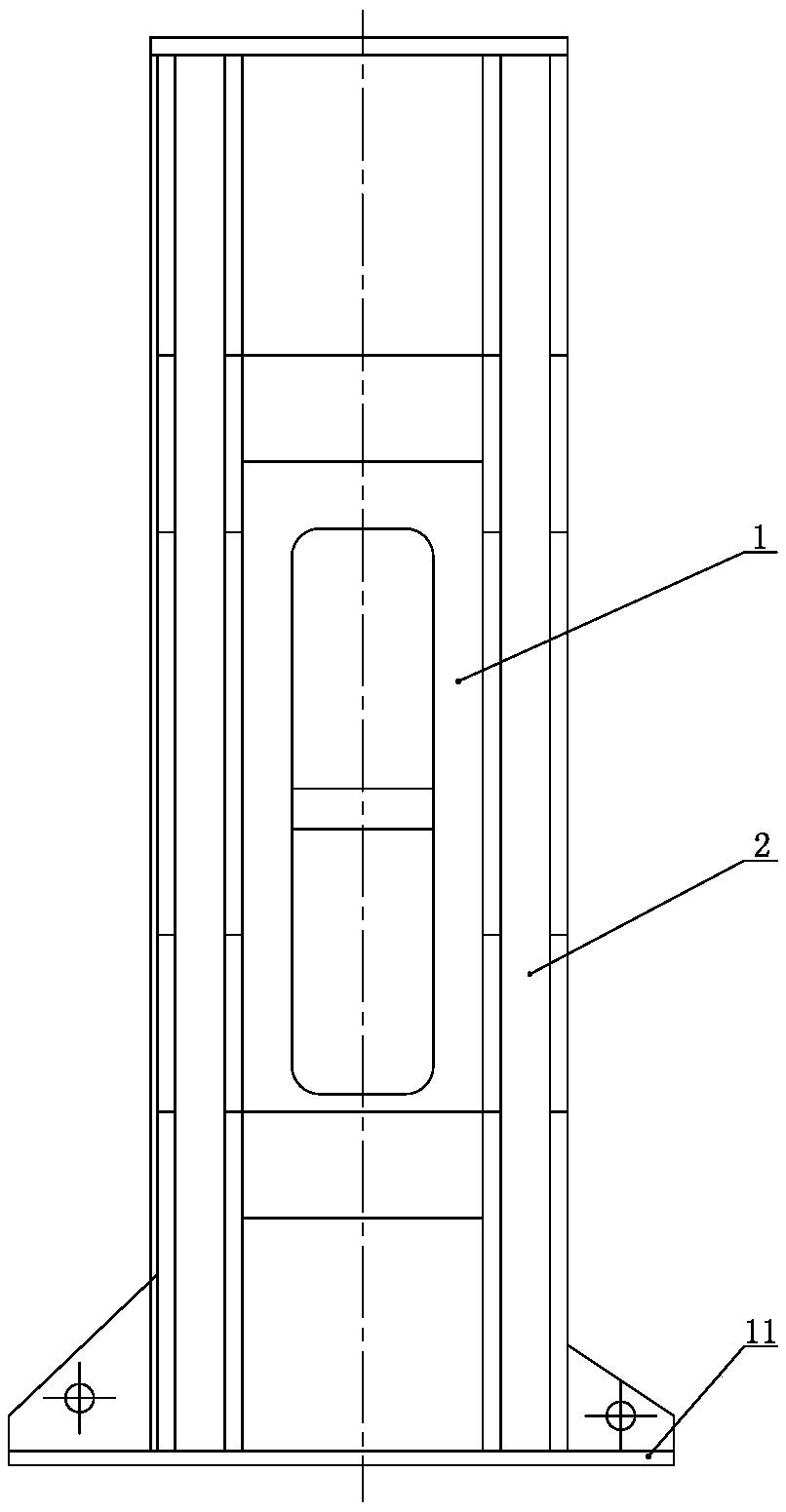

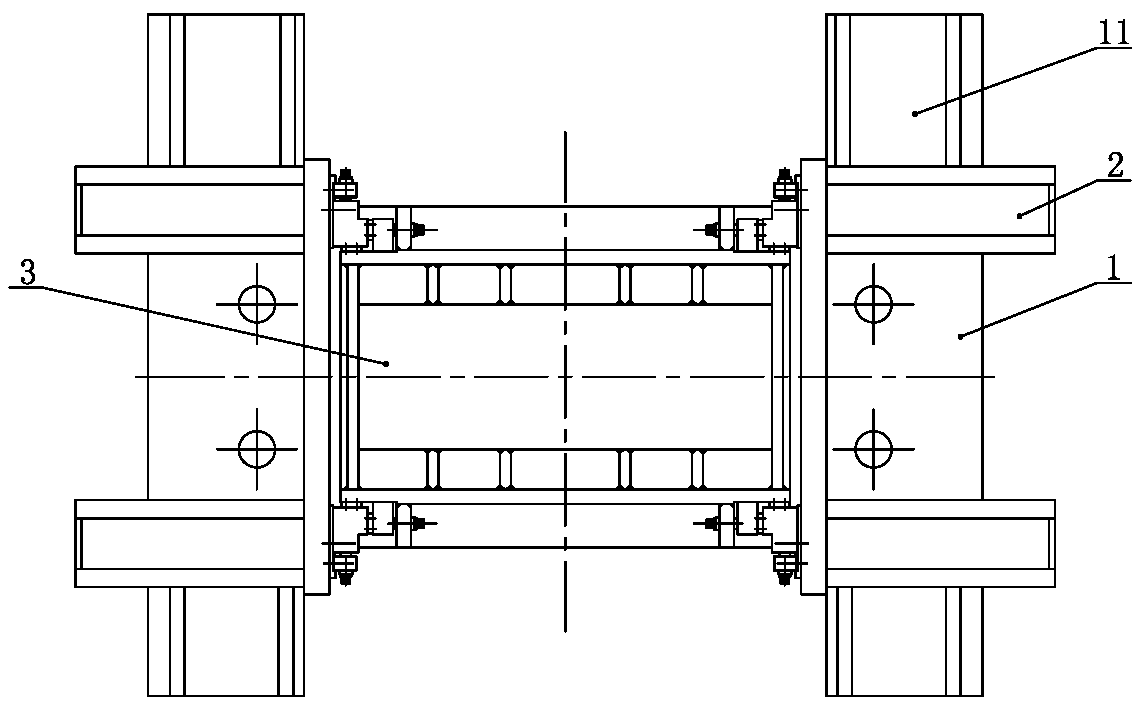

[0039] Such as Figure 1 to Figure 3 As shown, the servo pump-controlled hydraulic fine blanking machine of the present invention includes a fuselage 1, the four corners of the fuselage 1 are respectively supported on the base 11 by columns 2, and the tops of the four columns 2 are connected with upper beams 3, and the upper beams The center of 3 is equipped with a main cylinder 6, the driving end of the main cylinder 6 is hinged with the upper center of the slider 4, the base is provided with a workbench 5, the center of the bottom of the slider 4 is fixed with a punch 7, and the outer periphery of the punch 7 Nested with a pressure ring 8 that can float downwards, the top of the pressure ring 8 is connected to the upper hydraulic pad 8b through the pressure ring driving rod 8a, and the center of the upper hydraulic pad 8b is fixedly connected with the lower end of the plunger rod of the blank holder cylinder 8c. The side cylinder 8c is fixed in the slider 4; the upper guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com