Fatigue test device of automobile sliding column assembly and experiment method thereof

A technology of fatigue test and sliding column, which is applied in the direction of vehicle suspension/shock absorbing mechanism test, etc., can solve the problem of equivalent relationship that cannot guarantee road test or user consistency, and achieve reduced test cost, good repeatability, and shortened test cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

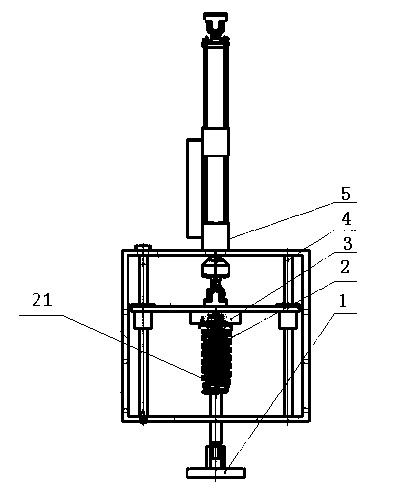

[0028] Combine below figure 1 and figure 2 , the present invention is further described:

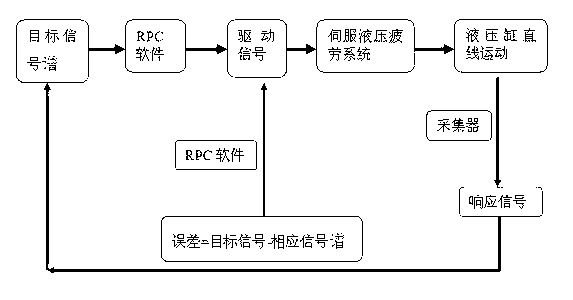

[0029] Such as figure 1 As shown, a fatigue test device for an automobile strut assembly, the two ends of the strut assembly 2 are respectively connected to the upper fixture 3 and the lower fixture 1, and the upper fixture 3 and the lower fixture 1 are the ends of the strut assembly 2. At the fixed end, the hydraulic actuator 5 is connected with the spool assembly 2 through the guide device 4; when the hydraulic actuator 5 moves up and down, it will make the coil spring 21 and the shock absorber of the spool assembly 2 simulate the vibration of the automobile when driving. The coil spring moves up and down; the strain sensor is attached to the outside of the coil spring 21 of the automobile sliding column assembly to collect the strain value of the spring, and the data collector collects the displacement value and force value of the hydraulic actuator 5; the computer collects the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com