Optical fiber cabin-penetrating sealing connection socket device used for sealing cabin

A technology for connecting sockets and sealed cabins, applied in the coupling of optical waveguides, etc., can solve the problems of complex sealing structure, difficult process, high additional loss, etc., and achieve the effect of good sealing performance, simple process and low additional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

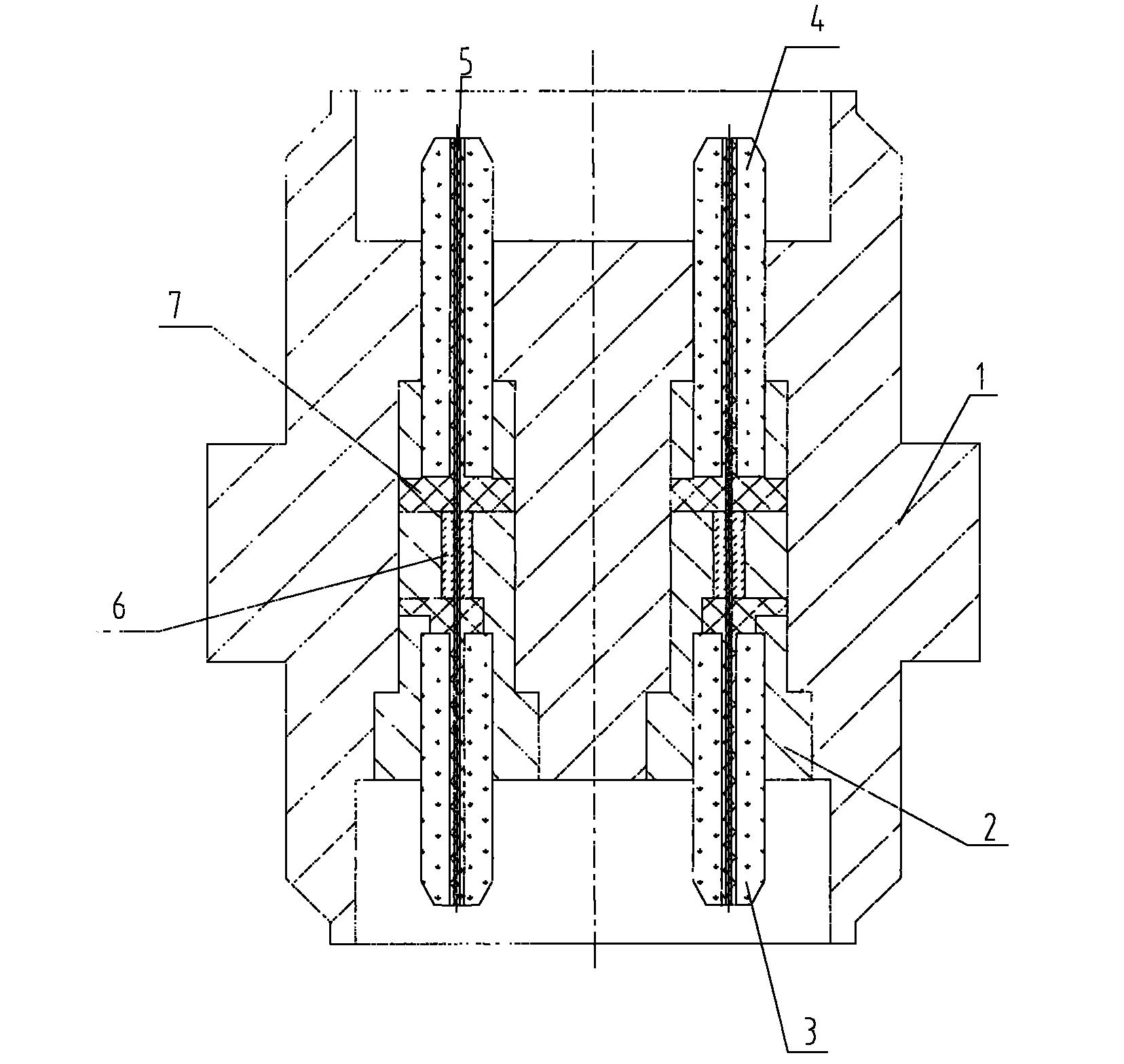

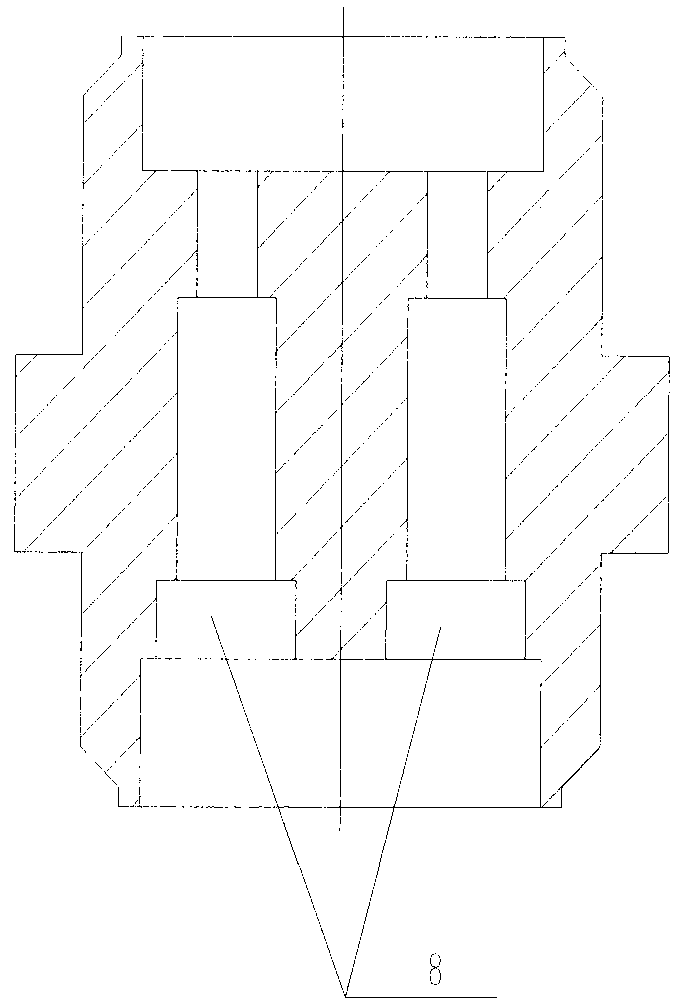

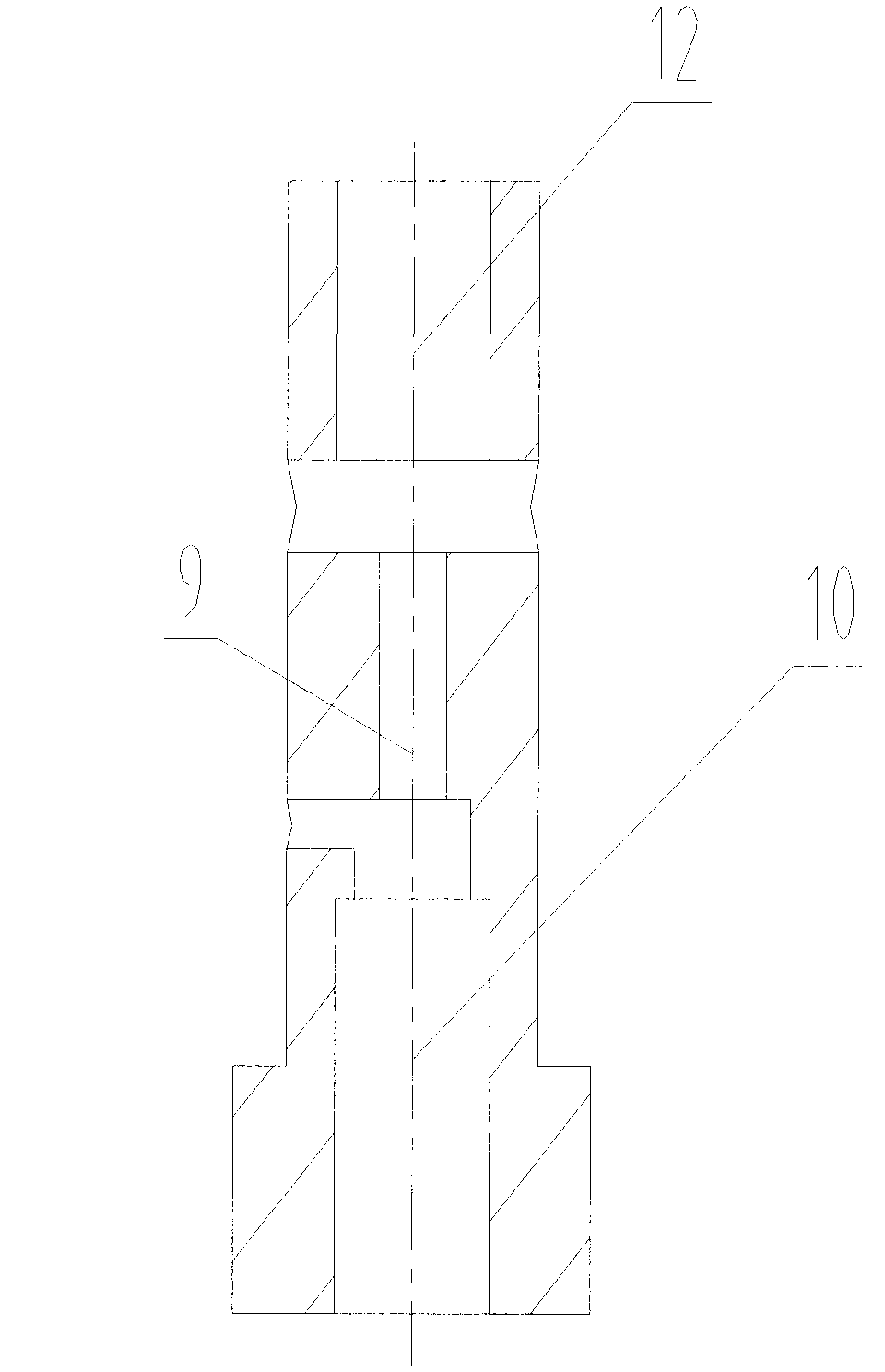

[0014] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention includes a sealing flange 1 , an optical fiber sealing seat 2 , an inner butt ferrule 3 , an outer butt ferrule 4 , and an optical fiber 5 . The outer butt joint ferrule 4 is loaded into the outer ferrule installation hole 12 of the fiber sealing seat 2 by press-fitting; the optical fiber 5 is inserted into the center hole 11 of the outer butt joint ferrule; Low-temperature glass solder, after heating and melting, seal and fix the optical fiber in the optical fiber sealing seat 2; put the inner butt joint ferrule 3 into the inner ferrule installation hole 10 of the optical fiber sealing seat 2; use epoxy glue 7 to separate the two ends of the optical fiber 5 Adhesively fixed in the inner butt joint ferrule 3 and the outer butt joint ferrule 4; process the end faces of the inner butt joint ferrule 3 and the outer butt joint ferrule 4 into a PC or APC type butt surface; the sealing flange 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com