Service life forecasting method and service life forecasting system of fan components

A technology of life prediction and components, applied in general control systems, control/regulation systems, computer control, etc., can solve the problem of inability to scientifically determine the timing of unit maintenance, prevention and maintenance methods, difficulty in realizing unit life early warning, and unreasonable planning of spare parts warehouses. and other problems, to achieve the effect of small sample data volume, reliable operation, and reduced monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Various example embodiments will now be described more fully with reference to the accompanying drawings, wherein like numerals refer to like parts throughout.

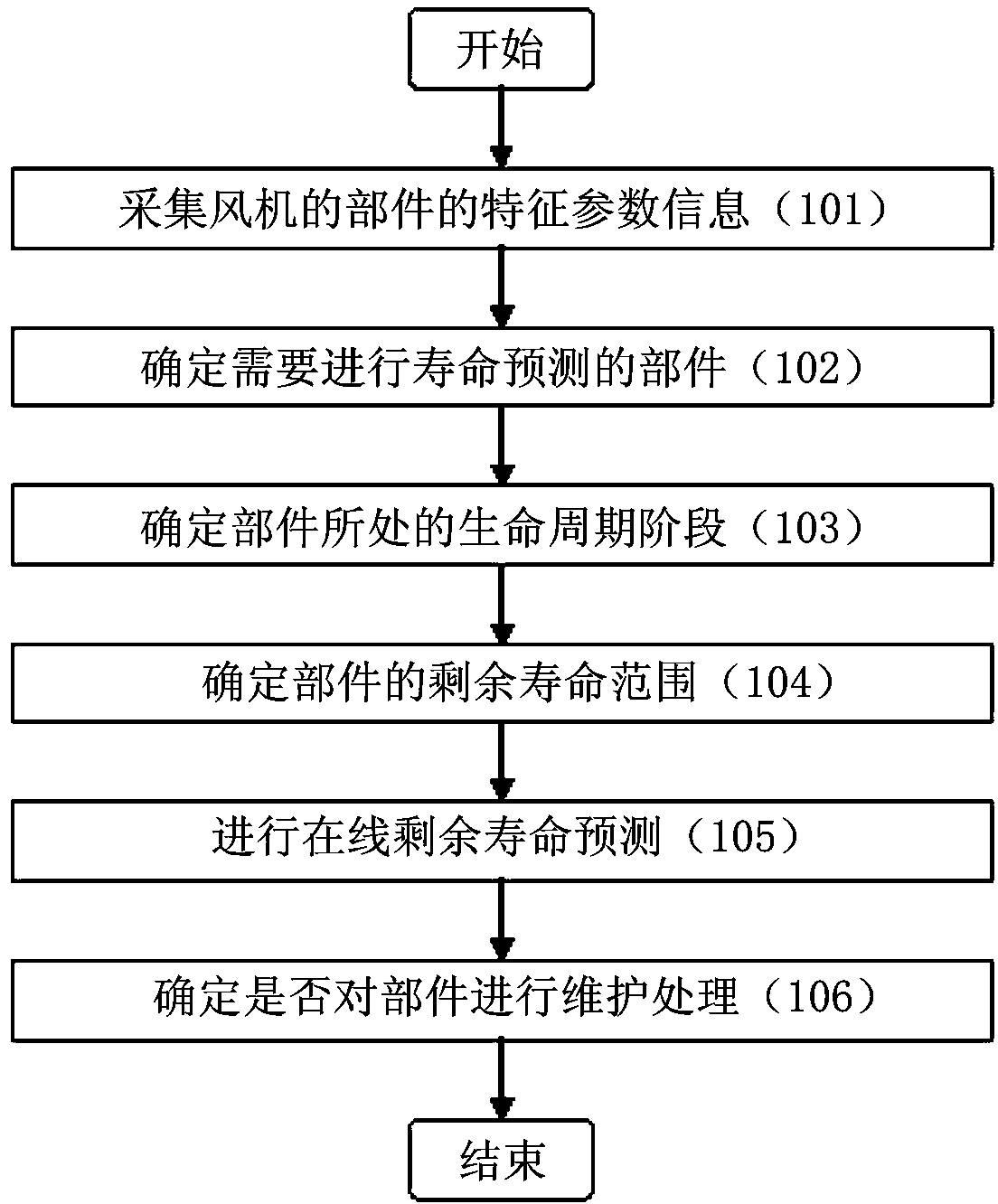

[0040] figure 1 A flow chart showing a life prediction method for fan components according to an embodiment of the present invention.

[0041] refer to figure 1 , in step 101, the characteristic parameters of the components of the fan are collected.

[0042]Characteristic parameters of various components of the fan can be collected by controlling various sensors installed in the fan. For fan components, characteristic parameters mainly include electrical characteristic parameters (such as current, voltage, frequency, etc.), mechanical characteristic parameters (such as vibration signals, magnetic field signals, speed signals, etc.), process parameters (such as wind speed, power , temperature, etc.).

[0043] In step 102, according to the characteristic parameters of the components of the wind turbine collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com