Dispatch method and system for low bridge electric trolleys in automated container wharf

An electric trolley and scheduling method technology, applied in instruments, data processing applications, logistics, etc., can solve problems such as the inability to explicitly represent the data flow, the search time limit of the solution method, and the inability to build a model that meets the real-time scheduling requirements of the terminal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

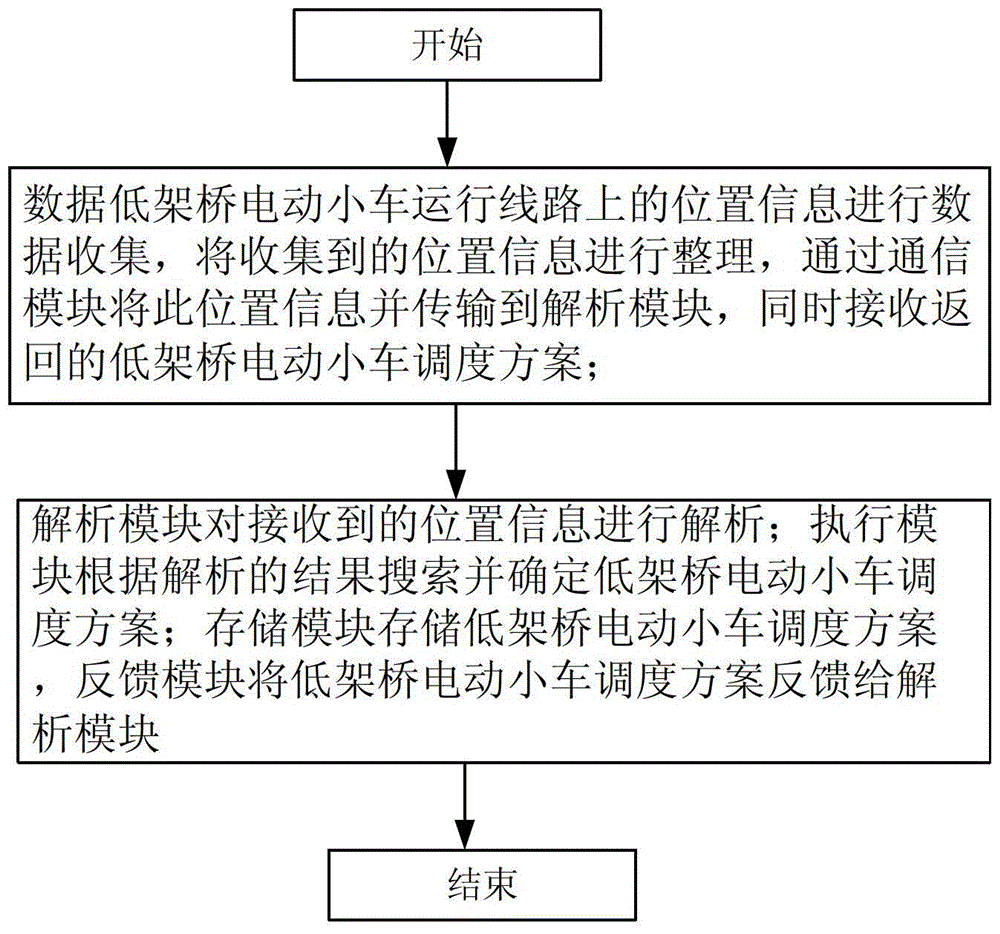

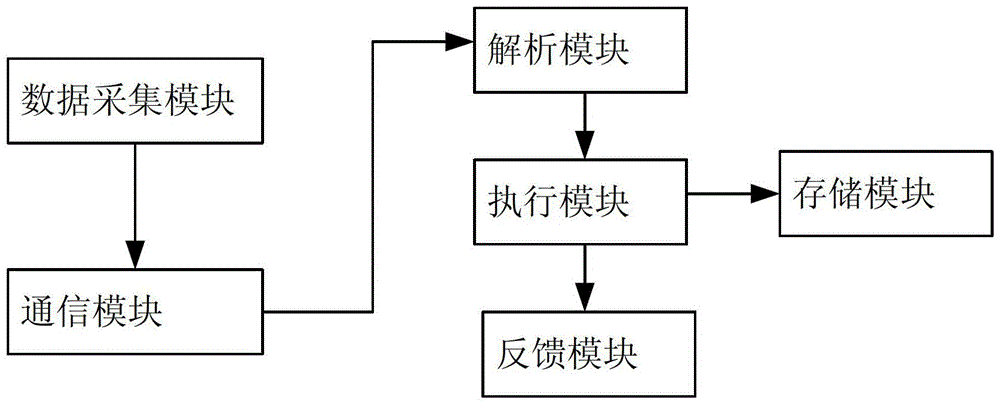

[0047] Such as figure 1 and figure 2 As shown, the automatic container wharf low bridge electric trolley dispatching method of the present invention adopts a data acquisition module, a communication module, an analysis module, an execution module, a feedback module, a storage module, and the data acquisition module, the communication module, the analysis module, and the execution module are sequentially connected , the feedback module and the storage module are all connected to the execution module, and the scheduling method includes the following steps:

[0048] Step S1: The data acquisition module collects data on the location information of the low-bridge electric trolley running line, organizes the collected location information, and transmits the location information to the analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com