A kind of inas avalanche photodiode and its manufacturing method

An avalanche photoelectric and manufacturing method technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as reducing the maximum gain bandwidth product, inconvenient to apply communication systems, limiting available gain, etc. current, the effect of reducing the tunneling dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

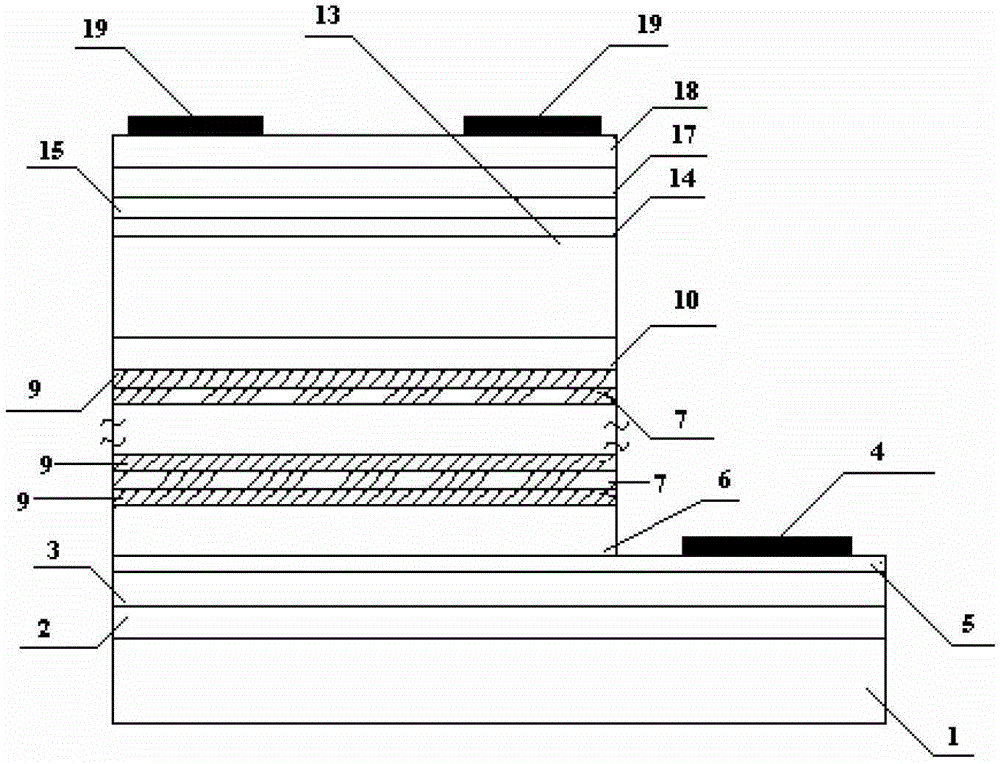

[0042] See figure 1 , When x=0.25, the multiplication layer (7, 9) uses Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 / InAs superlattice structure; the corresponding charge layer 10 uses Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 Material, the material of the graded layer is also Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 It is the same as the charge layer 10 and the multiplication layer 9, so this structure can be omitted. The following provides various structural materials and various parameter tables:

[0043]

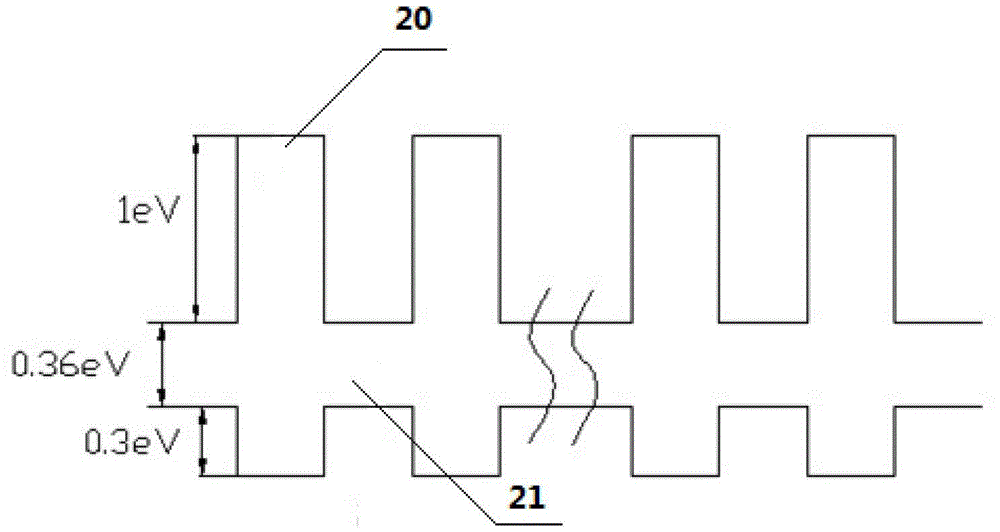

[0044] See Figure 7 , Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 Schematic diagram of the energy band of / InAs. Adopt Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 Material as light window layer 17, Al 0.25 Ga 0.75 As 0.1052 Sb 0.8948 The conduction band difference between the material energy band 22 and the InAs material energy band 21 is 0.77 eV, the valence band discontinuity is almost non-existent, and the band gap of the InAs material energy band 21 is 0.36 eV. It is transparent to incident light, can ...

Embodiment 2

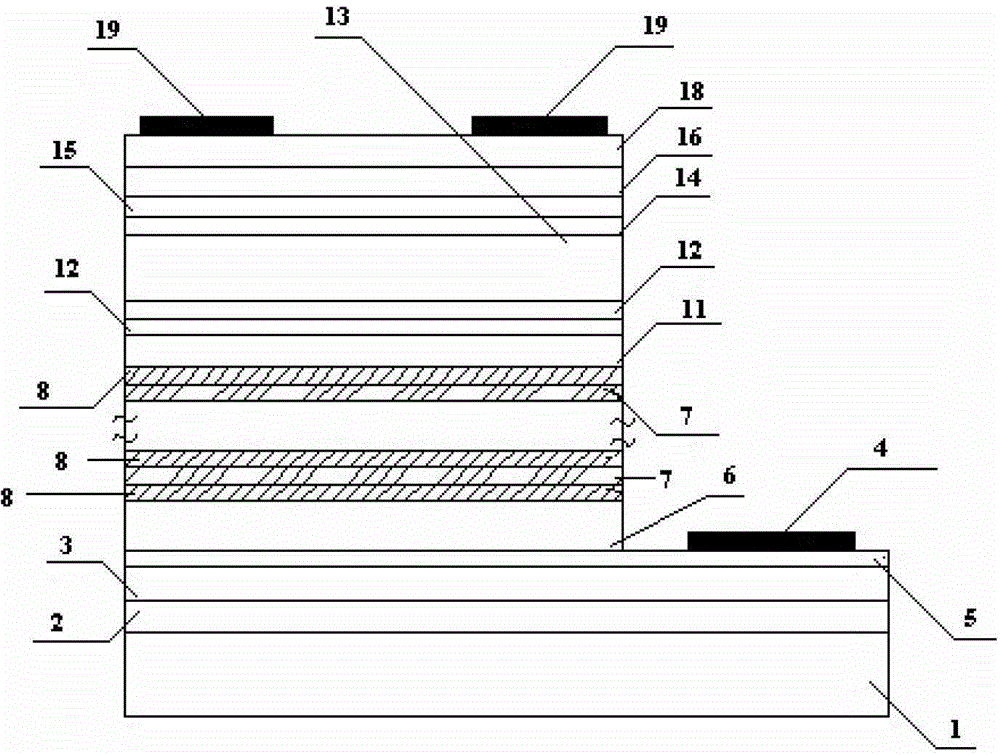

[0048] When x=1, the multiplication layer (7, 8) uses AlAs 0.16 Sb 0.84 / InAs superlattice structure, where the charge layer 11 is AlAs 0.16 Sb 0.84 material.

[0049] A structural material and various parameter tables at this time are given below:

[0050]

[0051]

[0052] This embodiment provides a special case. When x=1, the wide band gap material 8 of the multiplication layer adopts AlAs 0.16 Sb 0.84 . The graded layer 12 is composed of two materials with different compositions.

[0053] See Image 6 , Using AlAs 0.16 Sb 0.84 Material as light window layer 16, AlAs 0.16 Sb 0.84 The conduction band difference between the material energy band 20 and the InAs material energy band 21 is 1eV, the valence band difference is 0.3ev, and the band gap of the InAs material energy band 21 is 0.36ev, which is transparent to incident light and can block a few electrons to the intrinsic region The diffusion reduces the diffusion dark current. Wide band gap materials provide a certain potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com