Carbon dot with hawthorn as carbon source and preparation method of carbon dot

A technology of carbon dots and hawthorn, applied in the field of carbon dots and their preparation, can solve the problem of uneven size distribution of carbon dots, and achieve the effects of good size uniformity, more stable fluorescence performance, good pH detection and cell imaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a second aspect, the application provides a method for preparing carbon dots described in the first aspect, the method comprising the following steps:

[0039] Hawthorn is subjected to pyrolysis reaction to obtain carbonized powder;

[0040] Specifically, the decoction pieces of hawthorn can be placed in a crucible, put into a muffle furnace, and pyrolyzed at 300-450° C. for 30-90 minutes.

[0041] Pulverizing the carbonized powder, and performing at least one water bath and suction filtration to obtain a concentrated solution, wherein the concentrated solution contains part of the carbonized powder;

[0042] Specifically, it can be pulverized with a pulverizer, and can be extracted twice in a water bath. The concentrated solution is obtained after suction filtration, and the purpose of suction filtration is to remove residues.

[0043] The concentrated solution is subjected to filtration, dialysis and high-speed gradient centrifugation to purify the concentrated s...

Embodiment 1

[0056] 1. Preparation of carbon dots.

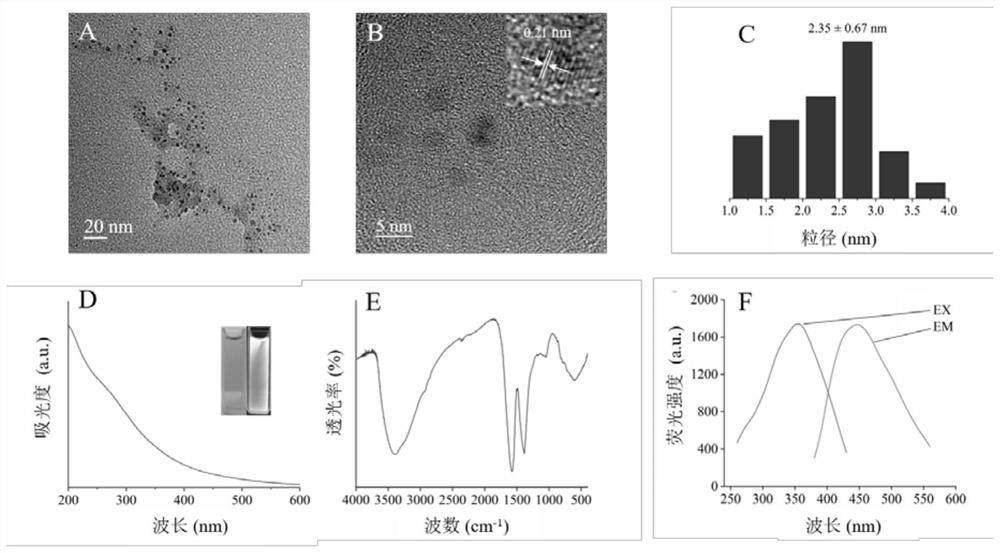

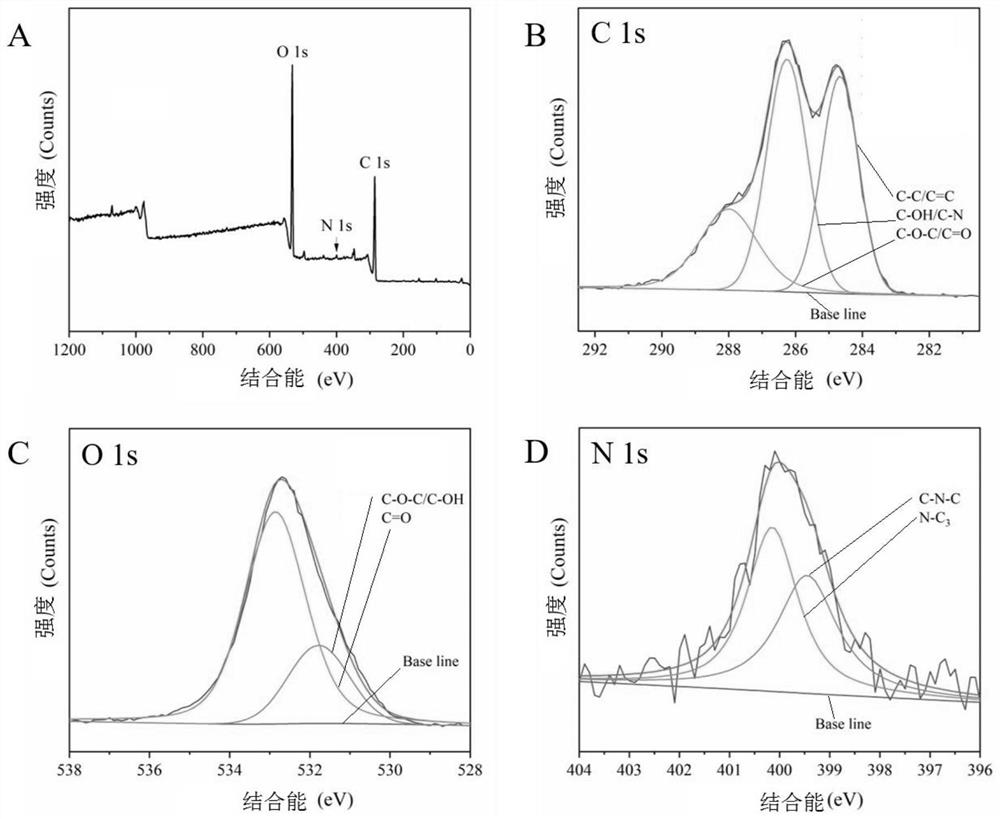

[0057] Take hawthorn decoction pieces, place them in a crucible, put them into a muffle furnace, and pyrolyze them at 400°C for 1 hour. The pyrolyzed samples were pulverized with a pulverizer. Weigh 60 g of the sample powder after high temperature pyrolysis, add 20 times the amount of deionized water, heat it in a water bath at 100°C for 1 hour, filter it roughly with filter paper, add 20 times the amount of deionized water to the drug residue, heat it once in a water bath at 100°C, and coarsely filter it with filter paper. Filter and combine the filtrates. Concentrate the filtrate to 120 mL with a rotary evaporator, filter through a 0.22 μm microporous membrane, place the above filtrate in a 1000 Da dialysis bag, and dialyze in a beaker filled with deionized water for 24 hours. The obtained dialysate is separated and purified by ultra-high-speed gradient centrifugation. Specifically, the dialysate is centrifuged at 20,000 g for 0.5 h,...

Embodiment 2

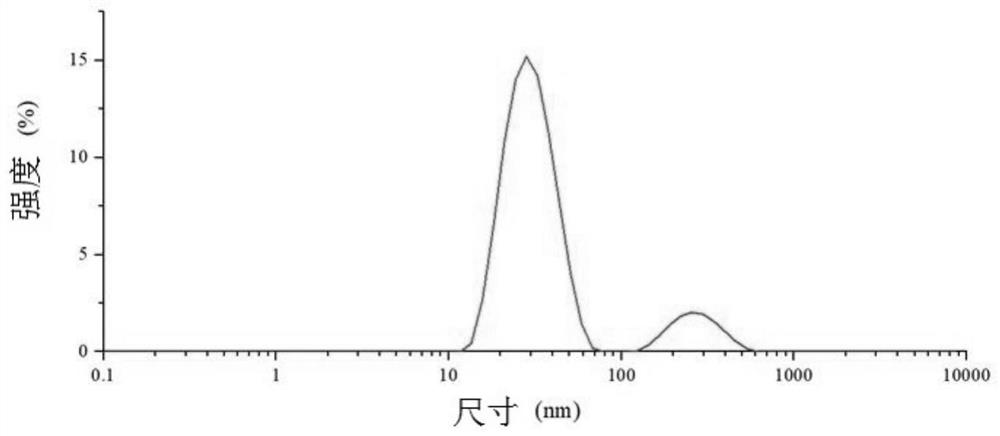

[0064] Purification method for preparing carbon dots using hawthorn as a carbon source: According to the preparation method of carbon dots described in Example 1, carbon dots prepared using hawthorn as a carbon source before ultra-high-speed gradient centrifugation purification were obtained. According to the conditions in Table 1, the ultra-high-speed gradient centrifugation conditions were screened, and the particle size distribution was investigated by DLS.

[0065] Table 1 Particle size distribution under different centrifugation conditions.

[0066]

[0067] Table 1 shows that under the conditions of centrifuging at 20000g for 0.5h, taking the supernatant at 100000g for 1.5h, and taking the supernatant at 200000g for 3h, a carbon dot solution with uniform particle size can be obtained. When the gradient centrifugation method is not used, the carbon dots cannot be effectively purified even if the rotation speed or time is increased.

[0068] The results of dynamic ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com