Anti-twist watertight device for underwater electric connector

An electrical connector, anti-torsion technology, applied in the direction of two-part connection device, parts of the connection device, connection, etc. The effect of uniform force, increased axial preload, and increased elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

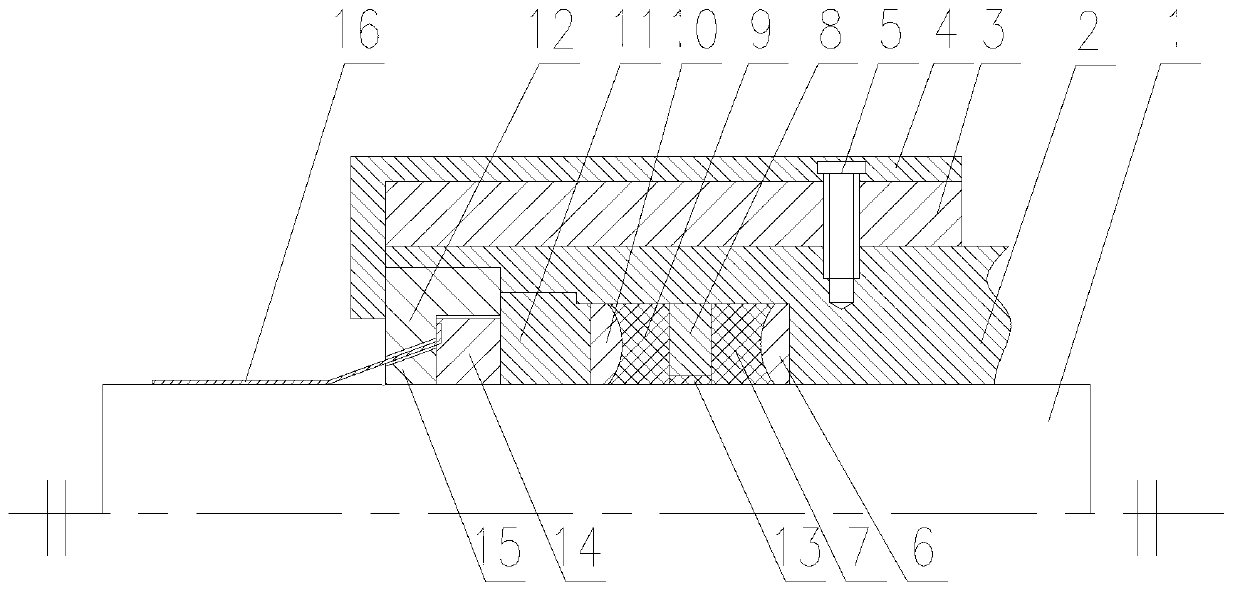

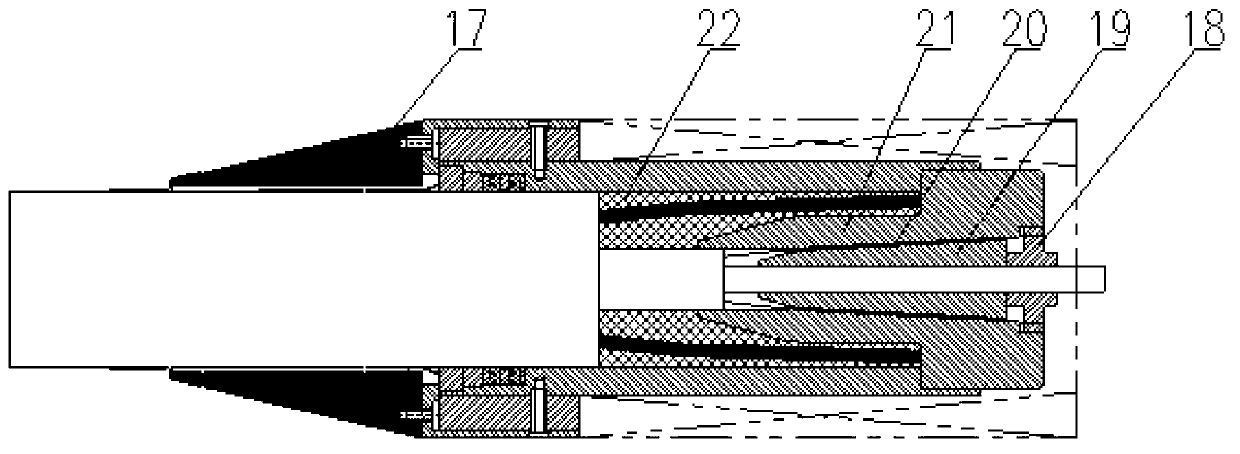

[0022] like figure 1 and 2 As shown, a watertight device for a torsion-resistant underwater electrical connector includes: a metal joint 2, an adjustment tube 3, an outer metal cover 4, a first cone 6, a first rubber pad 7, an isolation ring 8, The second rubber pad 9, the second cone 10, the cone cover 11, the wire sheath mounting plate 12, the rubber ring 13, the transition ring 14, the concave ring 15, the bell mouth wire mesh sleeve 16, the rubber protective sleeve 17, the locking Nut 18, hollow wedge-shaped column 19, load-bearing aramid fiber 20, positioning inner wedge column 21; peripheral equipment includes cable body 1;

[0023] Its connection relationship is as follows:

[0024] The metal joint 2 is a cylindrical structure with a radial three-step through-hole inside, and is sheathed outside the cable body 1; the first cone 6 is a hollow cylindrical structure, the left end face is hemispherical, the right end face is flat, and the right end face is flat. The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com