Intermediate joint of high-voltage cables

A technology for intermediate joints and high-voltage cables, applied in the direction of cable joints, etc., can solve problems such as poor sealing and hidden dangers of power cable safety, and achieve the effect of preventing water ingress, ensuring sealing effect, and high operating safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

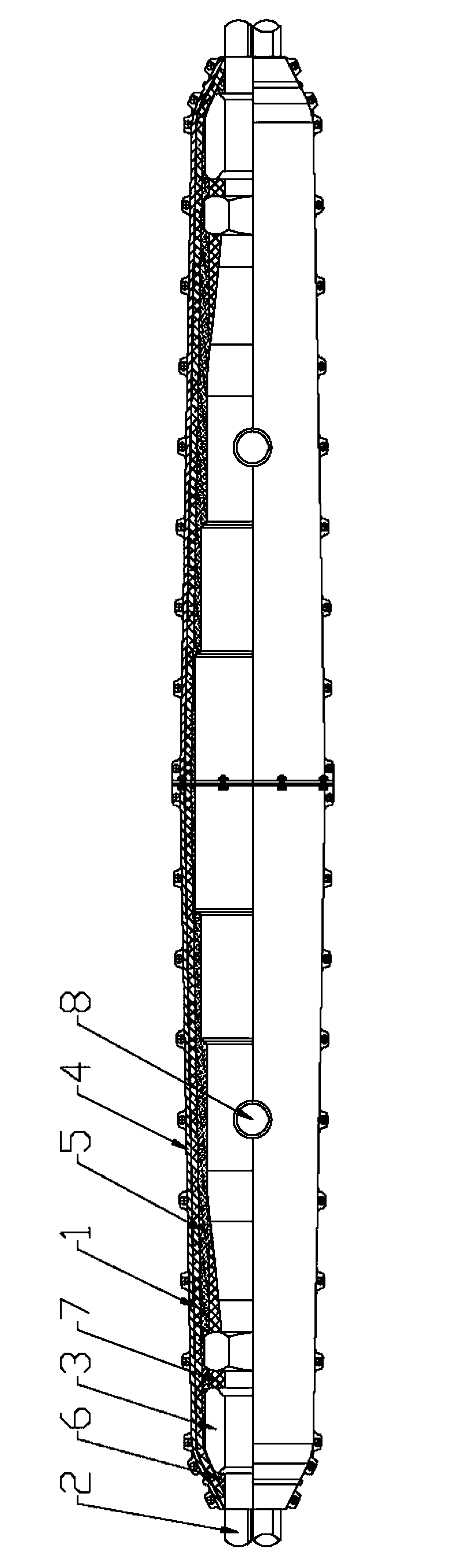

[0014] Such as figure 1 Shown: a high-voltage cable intermediate joint, including a cable sheath 1, a cable core wire 2, and a joint body 3 corresponding to the cable core wire 2 located in the cable sheath 1, and a protective cover is provided on the outside of the cable sheath 1 The box 4 and the protective box 4 are provided with an energy release hole 8. The energy release hole 8 is sealed by a special cover during operation, which can not only ensure the waterproof and moisture-proof of the cable joint during operation, but also prevent the internal discharge of the cable joint when the cable joint explodes. Release the pressure in the specified direction to avoid damage to other facilities; between the cable sheath 1 and the joint body 3, there is a potting glue layer 5 for sealing, and the outer side of the joint body 3 is provided to seal the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com