Water-cooled motor

A technology of water-cooled motors and motor shafts, which is applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as unreliable reliability, reduced motor life, and increased failure probability, so as to improve safety and reliability, and reduce temperature. rise, the effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

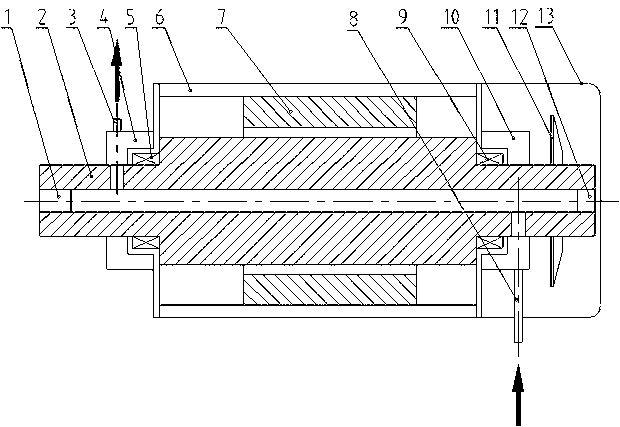

[0015] figure 1 Among them, the motor shaft 2 and the stator 7 are placed in the housing 6 . The motor shaft 2 is mounted on the housing 6 through the left bearing 5 and the right bearing 9 . Both ends of the motor shaft 2 are provided with a left sealing body 1 and a right sealing body 12 . The inside of the motor shaft 2 has a cooling water passage running through the inside of the motor shaft 2 , and the cooling water passage has interfaces respectively connected with the left rotary joint 4 and the right rotary joint 10 arranged at both ends of the motor shaft 2 . There is a left cooling water interface 3 on the left rotary joint 4 and a right cooling water interface 8 on the right rotary joint 10 . The cooling water can enter from the left cooling water interface 3 and flow out from the right cooling water interface 8, or can enter from the right cooling water interface 8 and flow out from the left cooling water interface 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap