Winding tooth and component for an electrical machine for reducing eddy currents

A winding and component technology, applied in the field of winding teeth, can solve the problems of reducing motor efficiency and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

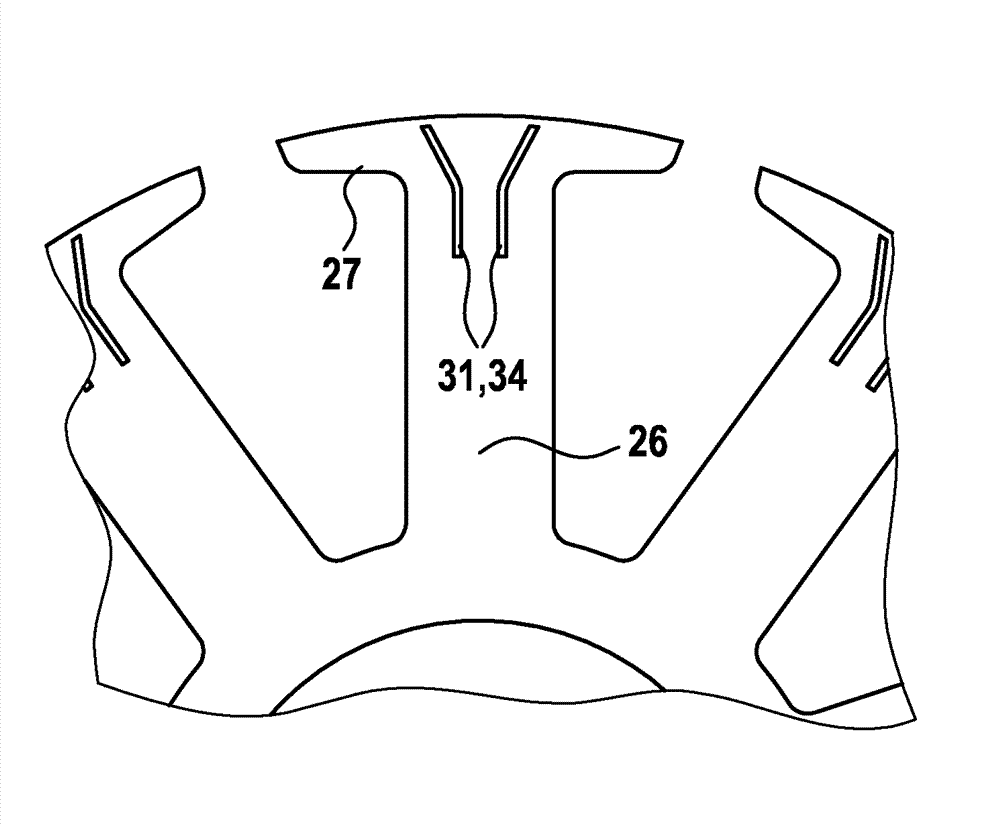

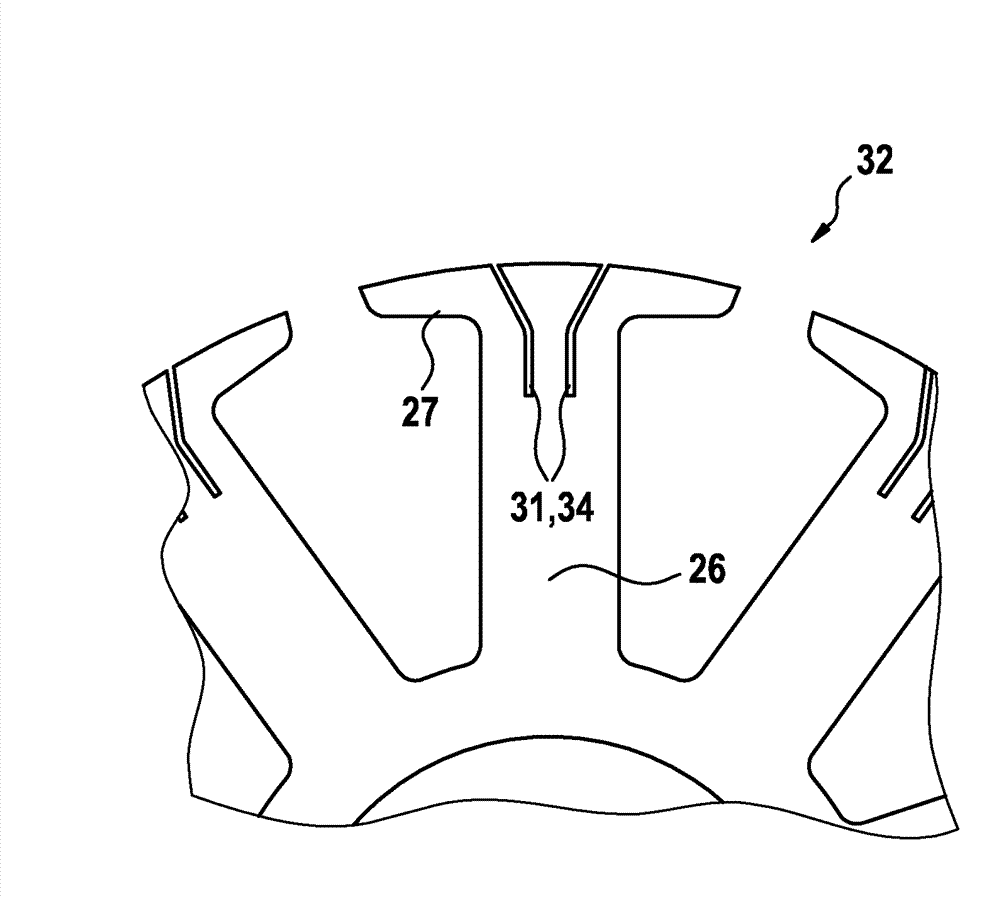

[0040] figure 1 A schematic cross-sectional view of a three-phase brushless permanent excitation motor with internal rotating parts, for example represented by motor 1 , is shown. The electric machine 1 comprises a cylindrical stator 2 with inwardly directed stator teeth 3 . In the present exemplary embodiment, the stator 2 comprises twelve stator teeth 3 which are each wound with a stator coil 4 as a winding coil. The stator coils 4 are connected to one another according to known wiring diagrams for three-phase motors.

[0041] A tooth tip 5 is provided on the inwardly directed end of the stator tooth 3 , which correspondingly has an outer contour opposite the tooth shank. The outer contour of the tooth tips 5 forms an inner recess 6 which is substantially concentric with the cylindrical stator 2 .

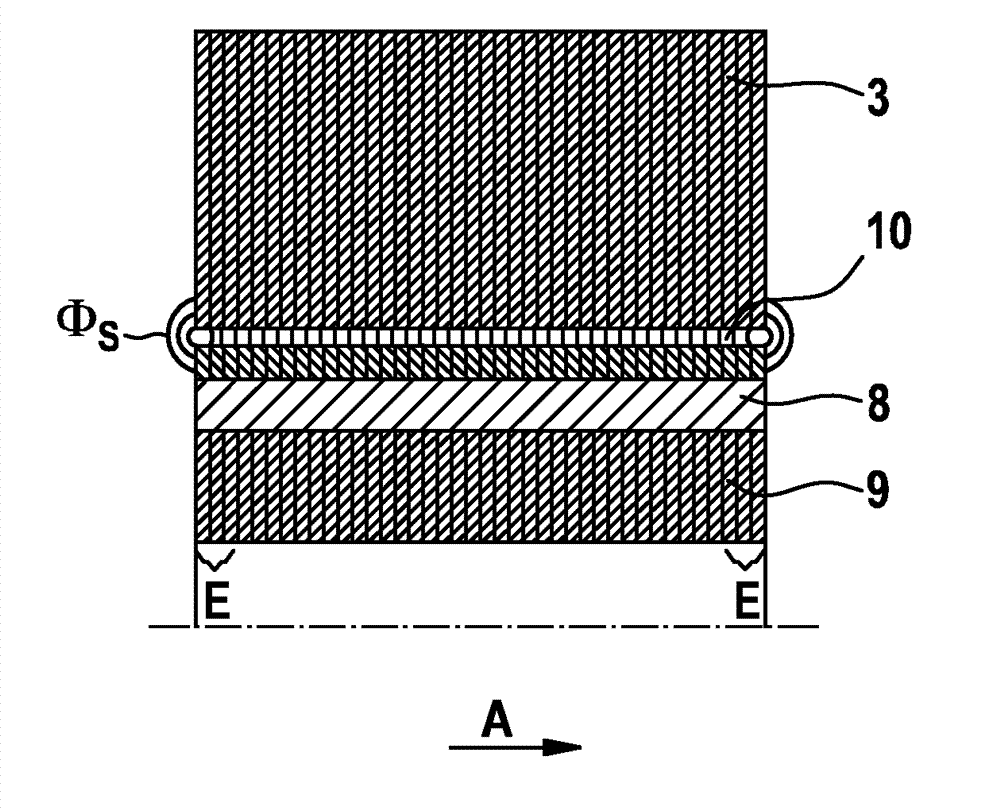

[0042] The rotor 7 is arranged in the interior space as a rotating part of the electric machine 1 . In this exemplary embodiment the rotor 7 has permanent magnets 8 which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com