Rotor for electrical machine, in particular for a synchronous motor

A motor and rotor technology, applied in the field of rotor structure, can solve problems such as complex and heavy structures, and achieve the effect of low manufacturing cost and excellent smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

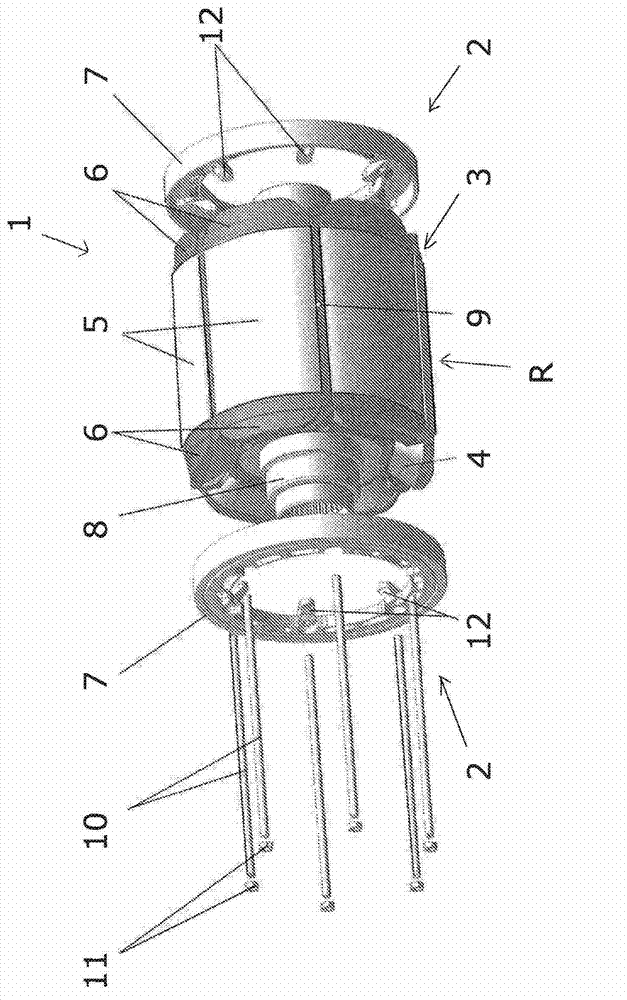

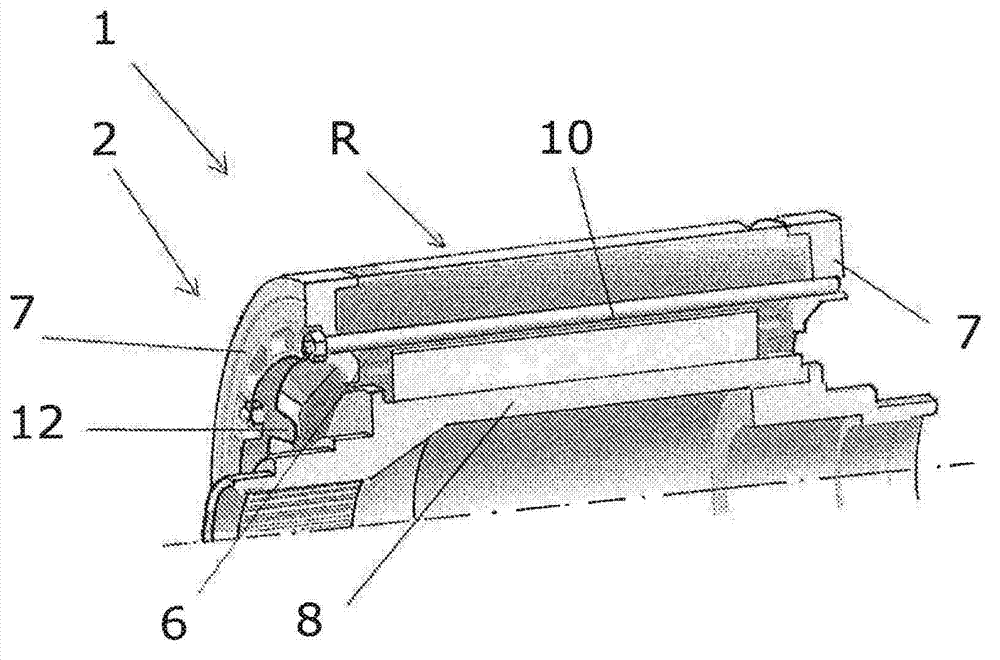

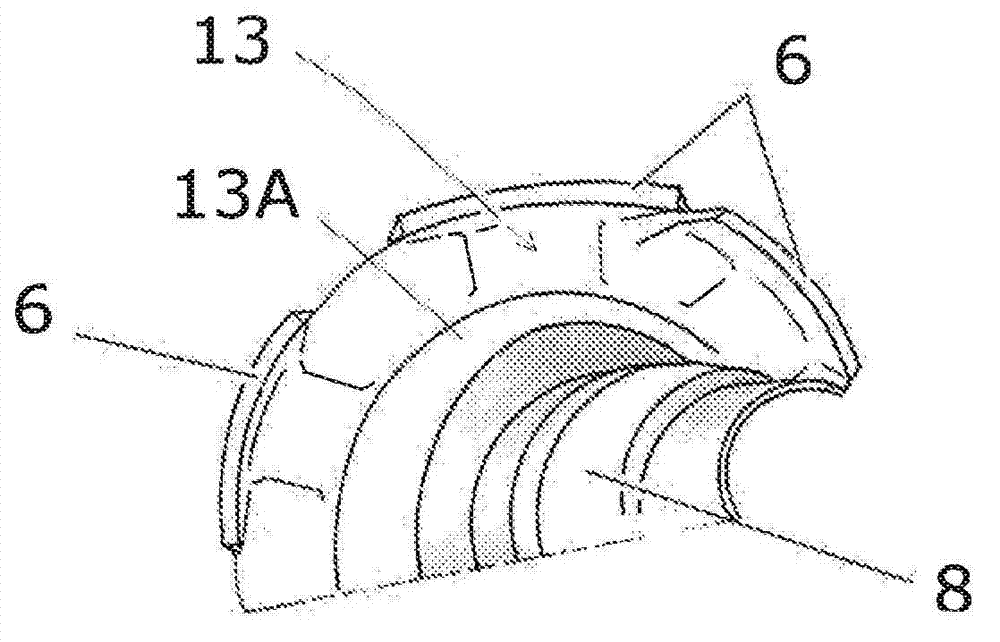

[0031] figure 1 A rotor assembly 1 according to the invention is shown comprising a rotor R shown in an exploded view and an exemplary embodiment of the proposed restraint system 2 . The restraint system 2 according to the invention comprises inner end caps 6 at both ends and a corresponding outer support ring 7 and is generally arranged as a protection device in order to fully restrain the winding ends 4 projecting from the laminations 3 in the axial direction. It is supported on both front sides of the rotor R and on the winding regions that may occur between the pole shoes 5 of the rotor R, even at relatively high rotational speeds of the rotor R. existfigure 1 In , the axis of the rotor R is denoted by reference numeral 8 .

[0032] The rotor assembly 1 provided with the restraint system 2 according to the invention is especially suitable for the rotor R of a current-excited synchronous motor (SSM) or other electric motors having windings on the rotor, which are used in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com