Corrugated plate structured packing with embedded-type end surfaces and manufacturing method thereof

A structured packing, embedded plate technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problem of rising, affecting the normal operation of packed towers, packing heat transfer, and mass transfer efficiency It can improve the heat transfer of the packing, eliminate the wall flow effect, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

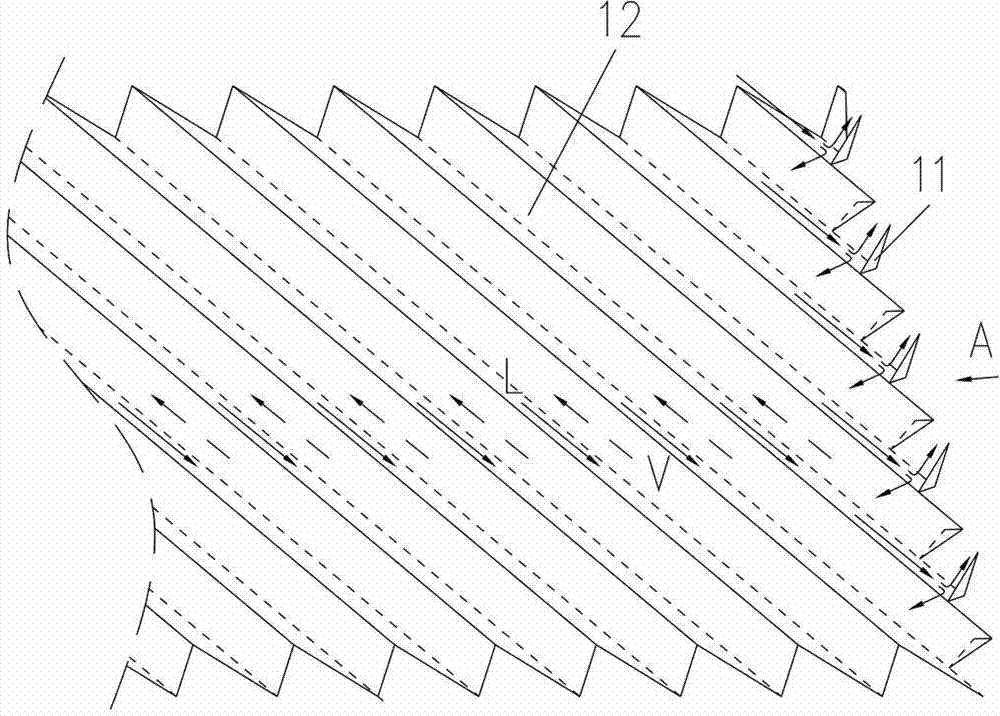

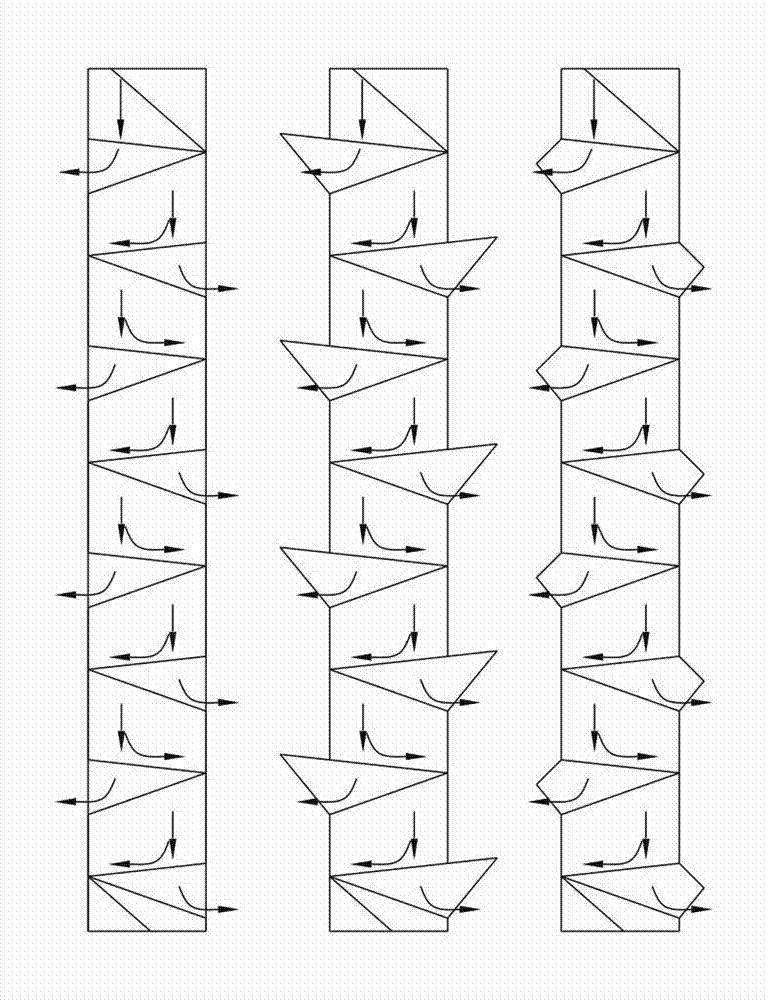

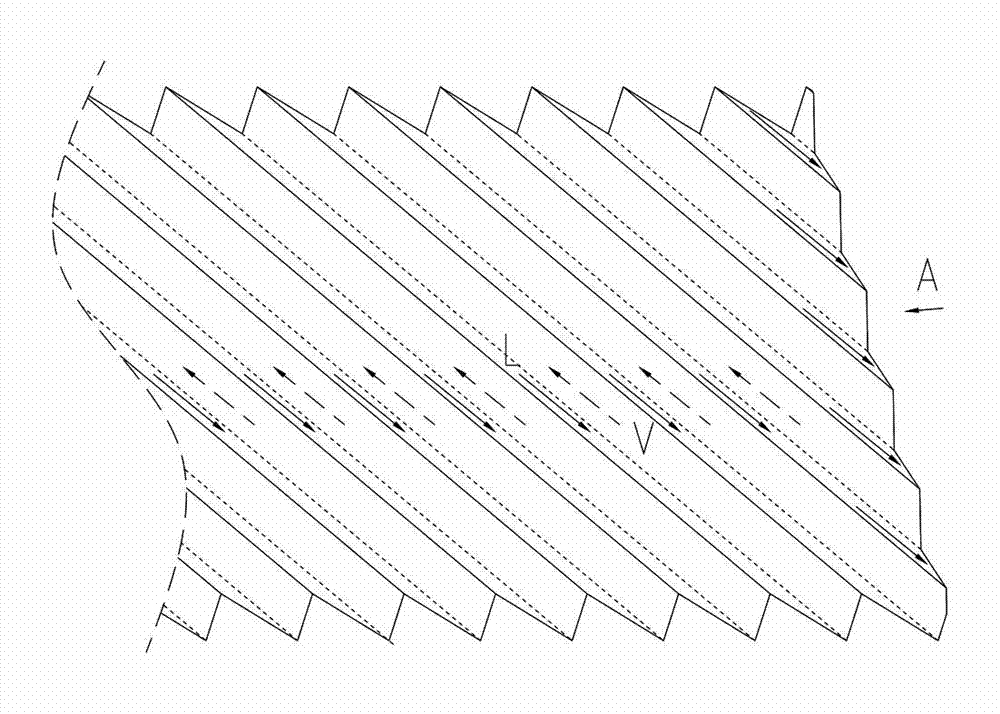

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples: the present invention is mainly composed of packing sheets to form a disc-shaped packing, the end faces of the packing sheets adopt a mutual embedded structure, and the single-piece flow channel has a non-straight-through structure for mutual drainage; The middle area on the packing sheet retains the structural form of the conventional plate corrugated packing and forms a gas and liquid channel in the main body of the packing that allows the gas and liquid to contact each other for heat transfer and mass transfer.

[0021] The end faces of both sides of the cut filler sheet can be embedded into each other after being cut and bent by the saw blade, and the overhanging part of each end face of the filler sheet is not less than the thickness of the filler sheet and not more than the thickness of the adjacent filler sheet.

[0022] The lines between the adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com