Splitting type rotor for powder concentrator and manufacturing process of splitting type rotor

A split-type, powder separator technology, which is used in the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc., to achieve the effects of convenient storage, reduced operating costs, and improved production efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

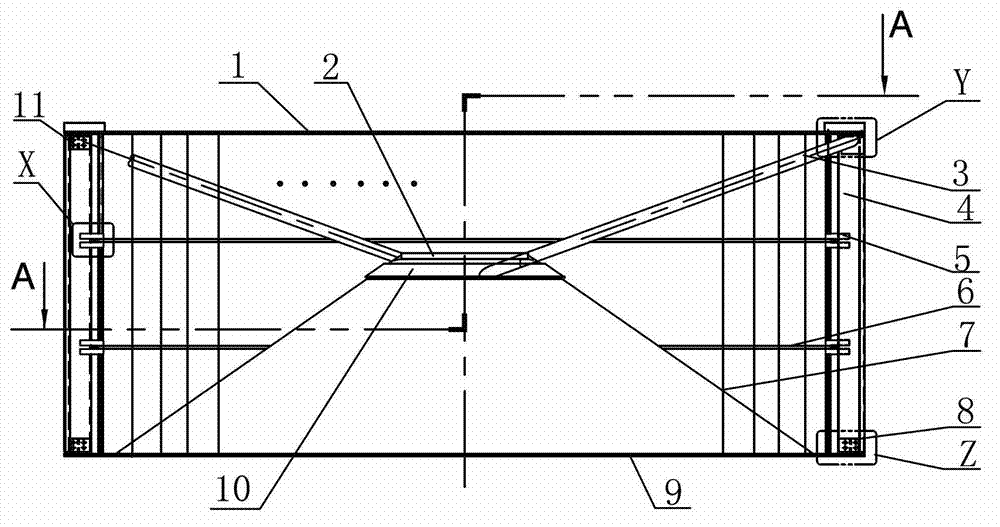

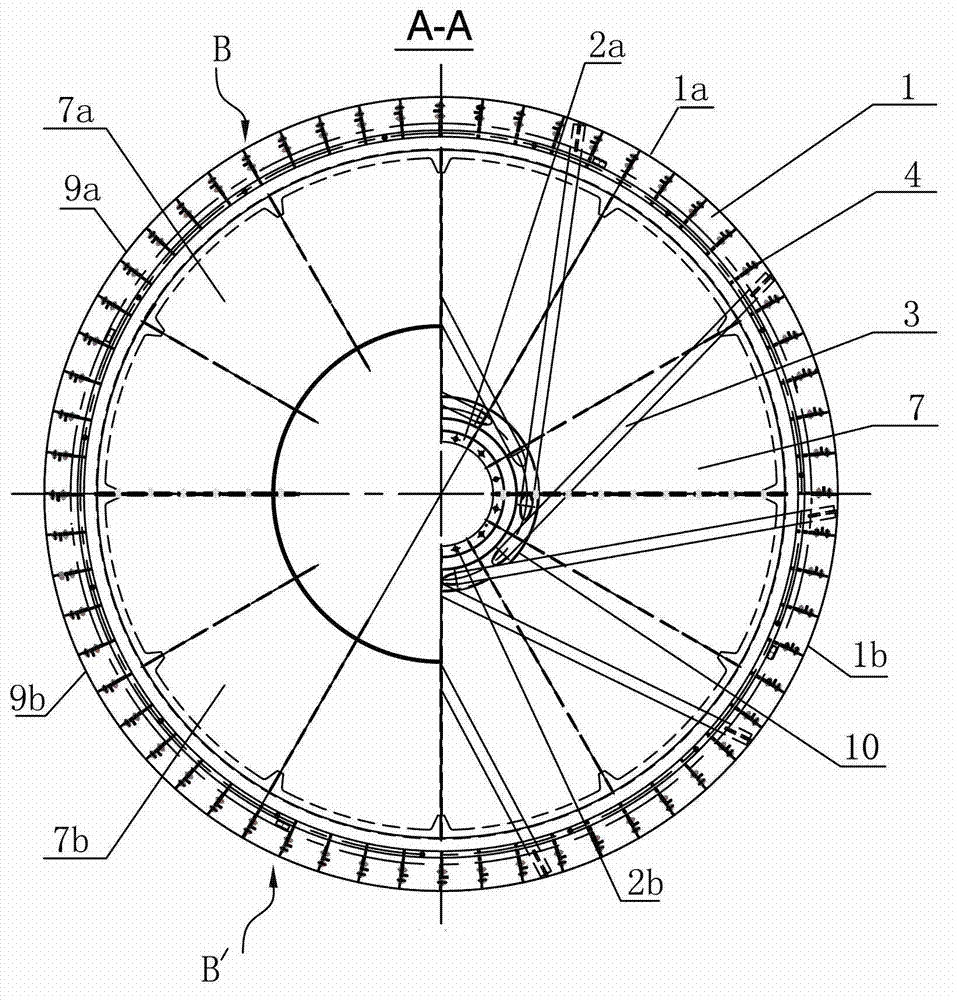

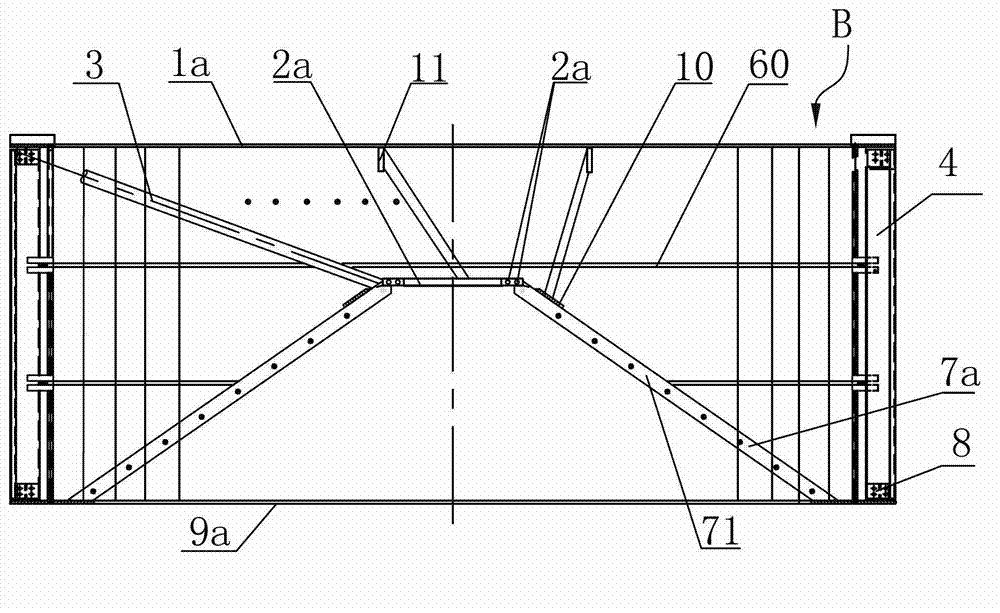

[0036] Figure 1 to Figure 10 A split rotor for a powder separator is shown, including a cage rotor body formed by coaxial circular upper and lower flanges 1, 9 and blades 4 uniformly distributed and fixed between the upper and lower flanges parallel to the above-mentioned axis and The rotor body is coaxially arranged inside the rotor cone 7, and the rotor cone 7 is a conical cylinder whose bottom edge is fixedly connected to the above-mentioned lower flange 1 and the top edge is connected to the cone flange 2. It is characterized in that the above-mentioned split rotor is It is composed of two semi-circular rotors B and B' that are separated by the plane of the axis butt joint. The above-mentioned semi-circular rotors B and B' respectively include a semi-circular cage-type rotor body formed by semi-circular upper and lower flanges and blades, a semi-circular rotor cone and a The semicircular rotor cone connected semicircular flange, that is, the semicircular rotor B includes ...

Embodiment 2

[0043] The present invention also provides a manufacturing process of the above-mentioned split rotor for the powder classifier, and specifically elaborates the following steps embodying the characteristics of the process in conjunction with Example 1:

[0044] ⑴Material preparation, according to product design requirements, prefabricated the upper and lower flange splicing sections with even segments respectively, the rotor cone 7 with ring cone reinforcement slat 10 composed of two semicircular rotor cones 7a, 7b movably connected, composed of two The conical flange 7, the upper and lower connecting plates 11, 8 and the blade 4 formed by the movable connection of the semi-conical flanges 7a and 7b, according to embodiment 1, two semi-circular upper flanges 1a, 1b, lower flange 9a, When 9b is used in combination, the joints are connected by welding, the semicircular rotor cones 7a, 7b are connected by bolts through the connecting edge 71 arranged along the joints, and the semi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com