Online testing method and measuring device of shape wave defects of hot rolled strip steel

A measuring device and technology of hot-rolled strip steel, applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of irregular uncertain changes of plate shape and wave shape defects, manual measurement, etc., and achieve improvement Effect of grading efficiency and grading quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

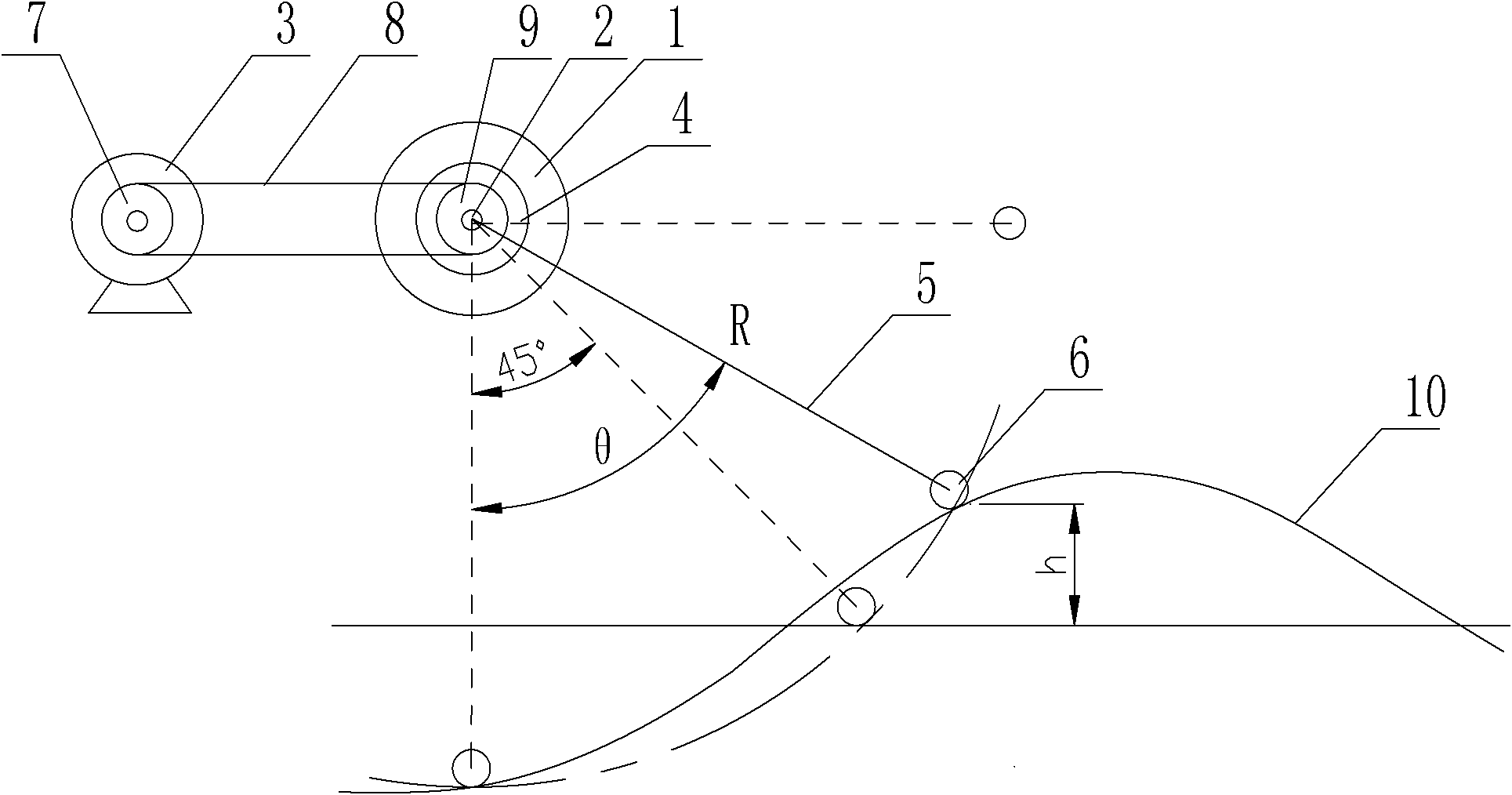

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] See figure 1 , is a structural schematic block diagram of an embodiment of an online method for detecting wave-shaped defects in hot-rolled strip steel according to the present invention. A wave-shaped defect measuring device is arranged at a fixed position above the strip steel on the entrance side of the hot-rolled sub-coil line. The device is provided with a pendulum 5, Along with the movement of the strip steel 10, the end of the swing rod 5 slides on the strip steel. By measuring the deflection angle of the swing rod 5, the wave height h at the position of the end of the swing rod 5 can be calculated. The specific operation steps are as follows:

[0017] 1) After the head of the strip 10 passes through the rolling mill, start the wave-shaped defect measuring device, the motor 3 rotates, the pendulum 5 falls from the horizontal initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com