Processing method of internal keyway of conical hole

A processing method and internal keyway technology, applied in the field of mechanical processing, can solve the problems of inapplicable processing and manufacturing, difficulty in scraping by fitters, lack of interchangeability of single parts, etc., and achieve high precision and avoid repairing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

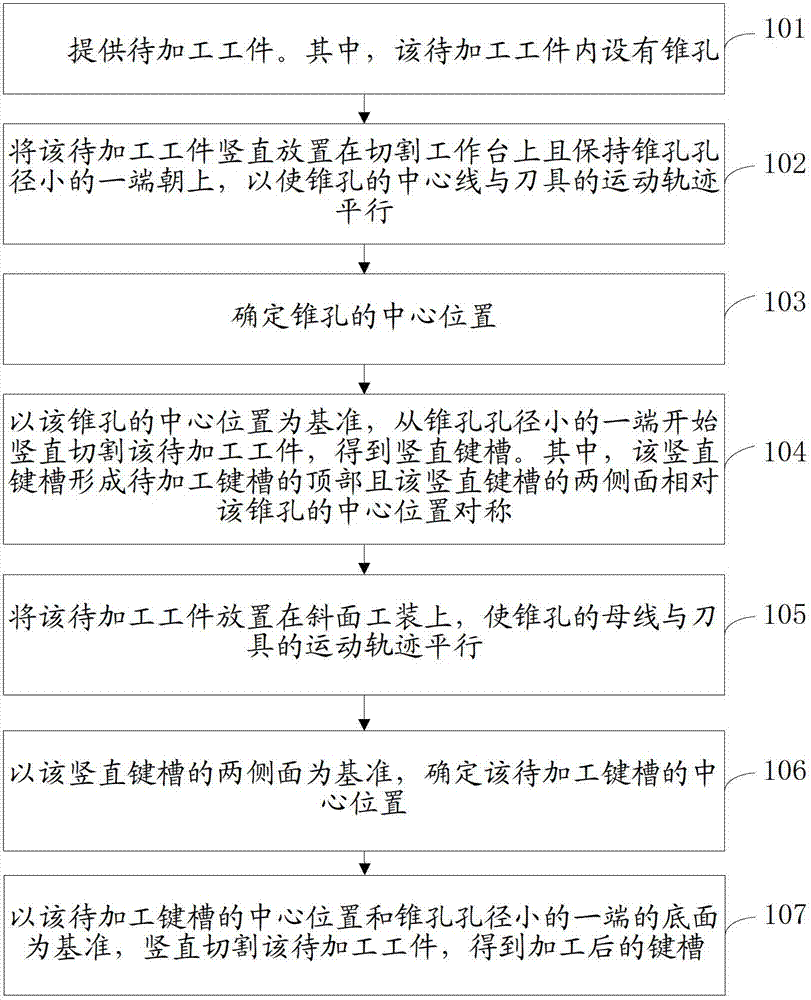

[0037] see figure 1 , the embodiment of the present invention provides a method for processing a keyway in a tapered hole, the process of the method includes:

[0038] 101: providing a workpiece to be processed.

[0039] Wherein, the workpiece to be processed is provided with a tapered hole.

[0040] 102: Place the workpiece to be processed vertically on the cutting workbench and keep the end of the tapered hole with the small diameter facing up, so that the center line of the tapered hole is parallel to the movement track of the tool.

[0041] 103: Determine the center position of the tapered hole.

[0042] 104: Taking the central position of the taper hole as a reference, vertically cut the workpiece to be processed from the end of the taper hole with a small diameter to obtain a vertical keyway.

[0043] Wherein, the vertical keyway forms the top of the keyway to be processed, and the two sides of the vertical keyway are symmetrical relative to the center of the tapered ...

Embodiment 2

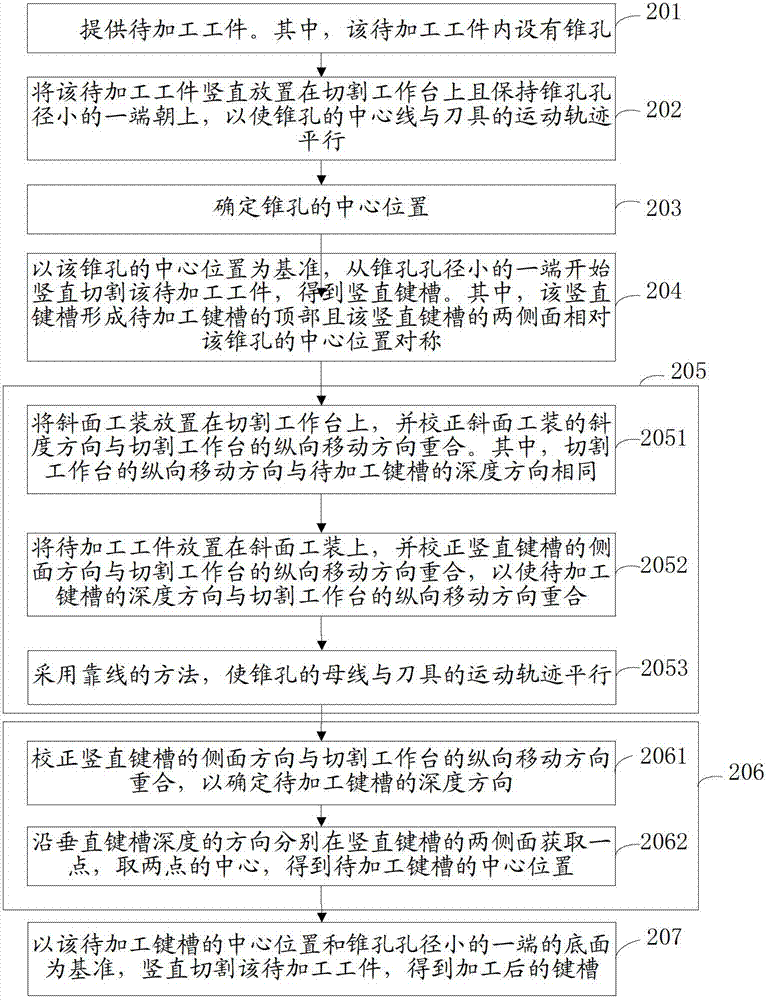

[0049] see figure 2 , the embodiment of the present invention provides a method for processing a keyway in a tapered hole, the process of the method includes:

[0050] 201: Provide a workpiece to be processed.

[0051] Wherein, the workpiece to be processed is provided with a tapered hole.

[0052] Further, a keyway processing line is drawn on the workpiece to be processed.

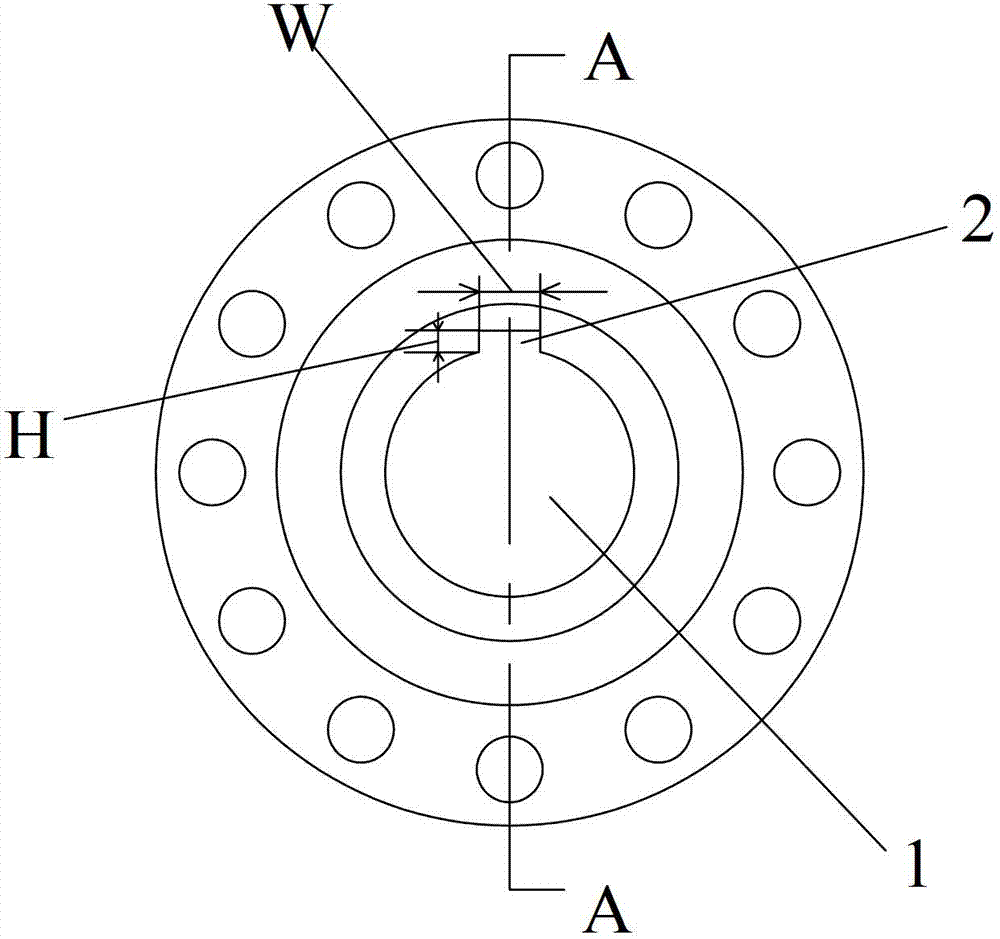

[0053] Specifically, the workpiece to be processed is a finished turning / finished part. The taper hole accuracy, surface roughness and shape and position tolerance of the workpiece should meet the drawing requirements. For example, see Figure 3 ~ Figure 4 , the workpiece to be processed is provided with a tapered hole 1, and the keyway 2 to be processed is arranged in the tapered hole 1. Assume that the width of the keyway 2 to be processed is W, and the depth (height) is H.

[0054] Among them, before machining the keyway, according to the requirements of the drawings, the keyway processing line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com