Unit combination type automatic stereoscopic warehouse system and control method

A three-dimensional warehouse and combined technology, applied in the field of three-dimensional warehouses, can solve the problems of non-reorganization, non-detachment, and inability to operate independently, so as to achieve the effect of improving operational efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

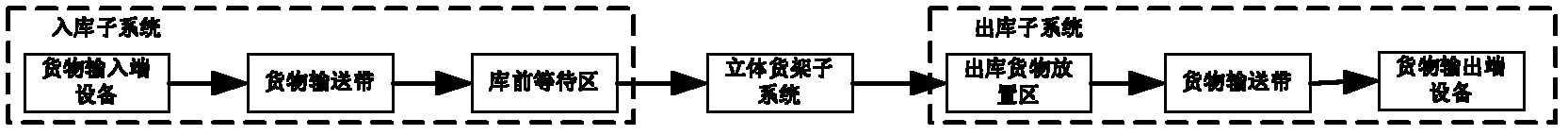

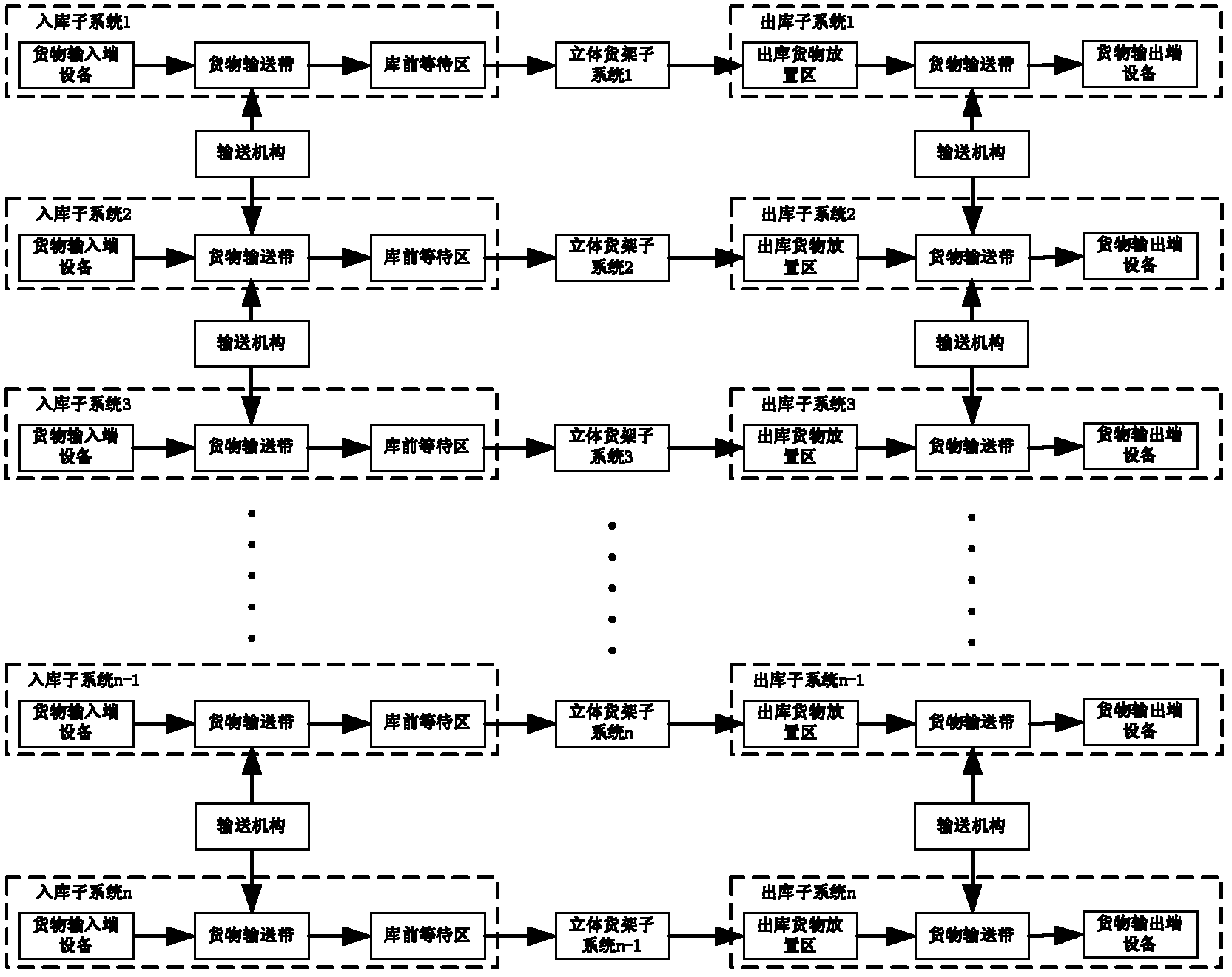

[0035] See figure 1 , figure 2 , The unit combined automatic three-dimensional warehouse system of the present invention is composed of a number of three-dimensional storage units. The three-dimensional storage unit is composed of a storage subsystem, a three-dimensional shelf subsystem, and a storage subsystem, wherein the storage subsystem It is connected with the three-dimensional racking subsystem, the three-dimensional racking subsystem is connected with the outbound subsystem, two adjacent inbound subsystems are connected through a conveying mechanism, and two adjacent outbound subsystems are connected through a conveying mechanism.

[0036] The three-dimensional shelf subsystem includes a three-dimensional shelf and a pickup mechanism. The pick-up mechanism is used to pick up the goods from the warehousing subsystem and store them in the corresponding storage location in the three-dimensional shelf, and transport them to the outbound subsystem after picking up the goods fr...

Embodiment 2

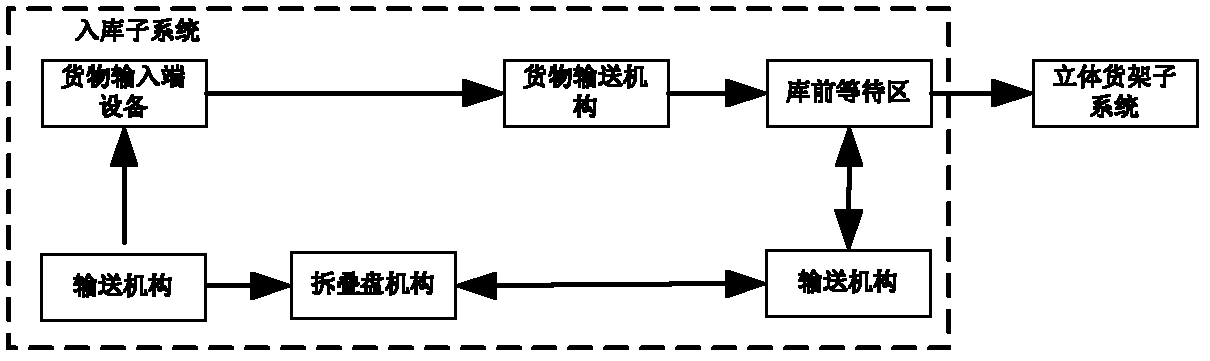

[0047] See image 3 , Figure 4 The difference between this embodiment and the first embodiment lies in the composition of the storage subsystem and the storage subsystem in the three-dimensional storage unit. The warehousing subsystem adds an unstacking tray system, including an unstacking tray mechanism and a conveying mechanism used to connect the cargo input terminal equipment and the waiting area in front of the warehouse, used to transport the entire stack of empty trays taken out of the three-dimensional rack to the unstacking tray After the organization performs the unloading operation, it is transported to the cargo input equipment with demand information; the unstacking disc system is added to the outbound subsystem, including the unstacking disc mechanism and the conveying mechanism used to connect the goods output terminal equipment and the outbound goods storage area. Used to transport the empty pallets carrying goods from each cargo output device to the unstacking ...

Embodiment 3

[0051] This embodiment provides a control method for a unit combined automated warehouse system, which is designed based on Embodiment 1 or Embodiment 2, and includes:

[0052] ①Using a modular programming method, design a unit control program corresponding to each three-dimensional storage unit. The unit control program includes a conveyor line control module for controlling the conveying state of the conveying mechanism, and a path for optimizing the optimal path of inbound and outbound transportation. The optimization module and the transmission line segment information database composed of inbound and outbound transmission line information. The transmission line control module is equipped with unit combination judgment logic. The path optimization module performs path optimization based on the data in the transmission line segment information library, and the transmission line control module is based on the path The optimization result of the optimization module and the sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com