Expansive agent, post-tensioned prestressed concrete channel grouting agent and grouting material

A channel grouting and prestressing technology, which is applied in the field of building materials, can solve the problems of reducing the expansion stress and affecting the expansion performance of the expansion agent, and achieves the effects of maintaining fluidity, high fluidity, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The expansion agent is composed of: 0.5 parts by mass of nitrogen-type expansion agent, 30 parts by mass of natural dihydrate gypsum and 10 parts by mass of light-burned magnesium oxide. The above-mentioned components are dry-mixed and uniformly mixed to obtain the expansion agent.

[0028] The channel grouting agent used in post-tensioned prestressed concrete construction is composed as follows: 8 parts by mass of powder polycarboxylate superplasticizer, 0.5 parts by mass of hydroxypropyl methylcellulose, 51 parts by mass of limestone powder and the above-mentioned 40.5 parts by mass of expansion agent. Each component material is dry-mixed and uniformly mixed to obtain a grouting agent.

[0029] Before grouting the prestressed tunnel, clean the prestressed tunnel and clean the grouting equipment. After cleaning, there should be no residue and obvious water in the equipment. The raw materials required for grouting are weighed in proportion, and the blending ratio of e...

Embodiment 2

[0032] The expansion agent is composed of: 0.5 parts by mass of nitrogen-type expansion agent, 30 parts by mass of natural dihydrate gypsum and 10 parts by mass of light-burned magnesium oxide. The above-mentioned components are dry-mixed and uniformly mixed to obtain the expansion agent.

[0033] The composition of the grouting agent is as follows: 8 parts by mass of powdered polycarboxylate superplasticizer, 6 parts by mass of calcium nitrite, 0.5 parts by mass of hydroxypropyl methylcellulose, 45 parts by mass of limestone powder and 40.5 parts by mass of the above-mentioned expansion agent. Each component material is dry-mixed and uniformly mixed to obtain a grouting agent.

[0034] The components and preparation process of the grout are the same as in Example 1.

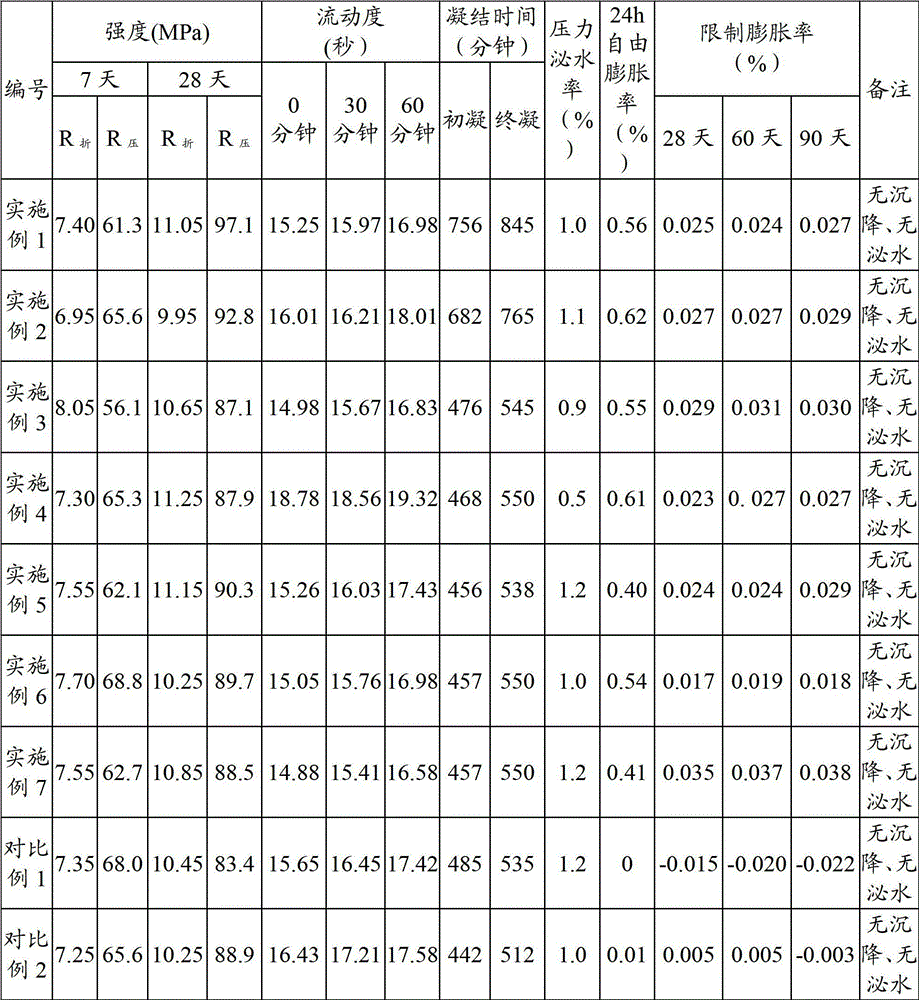

[0035] The performance index of the prepared grout was analyzed, and the results are shown in Table 1. From the data results corresponding to Example 2 in Table 1, it can be seen that the limiting expansion rati...

Embodiment 3

[0038] The expansion agent is composed of: 0.5 parts by mass of nitrogen-type expansion agent, 30 parts by mass of natural dihydrate gypsum and 10 parts by mass of light-burned magnesium oxide. The above-mentioned components are dry-mixed and uniformly mixed to obtain the expansion agent.

[0039] The composition of the grouting agent is as follows: 8 parts by mass of powder polycarboxylate superplasticizer, 10 parts by mass of calcium nitrite, 0.5 parts by mass of hydroxypropyl methylcellulose, 41 parts by mass of limestone powder and 40.5 parts by mass of the expansion agent. Each component material is dry-mixed and uniformly mixed to obtain a grouting agent.

[0040] The composition and preparation process of the grout are the same as in Example 1.

[0041] The performance index of the prepared grout was analyzed, and the results are shown in Table 1. From the data results corresponding to Example 3 in Table 1, it can be seen that the fluidity of the grout prepared in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com