Gear mechanism and geared motor

A technology of gear mechanism and motor, applied in the direction of gear transmission, electromechanical device, electric components, etc., can solve the problems of cracking, deformation, broken teeth and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

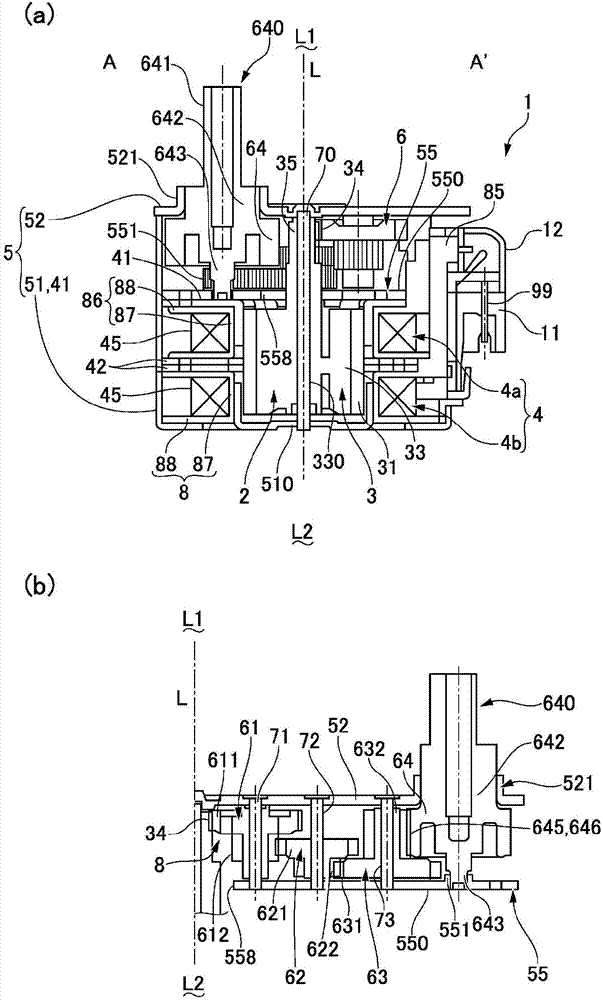

[0096] In the above embodiment, although the stopper 8 is provided on the input gear (gear 61 ), it may be provided on other gears 62 , 63 and the like.

[0097] In the above-mentioned embodiment, the stopper 8 is arranged on the gear mechanism 6 of the geared motor 1 with the motor 2 as the driving source, but the present invention can also be applied to the arrangement of the stopper 8 on the gear mechanism 6 driven by the motor 2 . The case on the gear mechanism 6 of the device other than the geared motor 1 of the source.

[0098] In the above-mentioned embodiment, on the stopper 8, the protruding part 617a is provided on two parts separated in the circumferential direction, and the recessed part 617b is provided on each of the protruding parts 617a at the two parts, but it is also possible A structure in which a continuous recess 617b is formed between the protrusions 617a provided at two locations is employed.

[0099] In the above embodiment, the first hole 649 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com