Semicircular spliced LED (Light-Emitting Diode) lamp bulb provided with embedded driver

An LED light bulb and splicing technology, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of low assembly efficiency, low welding efficiency, and high defect rate, and achieve high efficiency and reduce materials. and the effect of time wasted, uniqueness and reliability changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

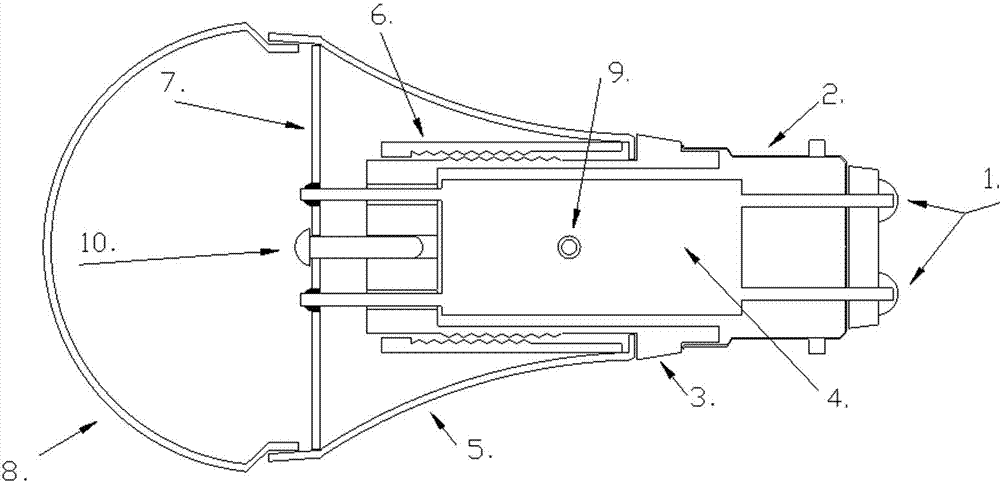

[0039] Example 1: see figure 1 , The two sets of connectors on the upper side of the PCB drive assembly 4 are arranged symmetrically along the center line of the PCB drive assembly 4. When the lamp holder 2 adopts the B22 model, the two sets of connectors on the lower side of the PCB drive assembly 4 are arranged horizontally and connected with the power terminal 1 of the lamp holder 2. Connect, and realize that the AC part of the PCB drive assembly 4 is introduced into the PCB body through the embedded lead wire to realize electrical conduction.

Embodiment 2

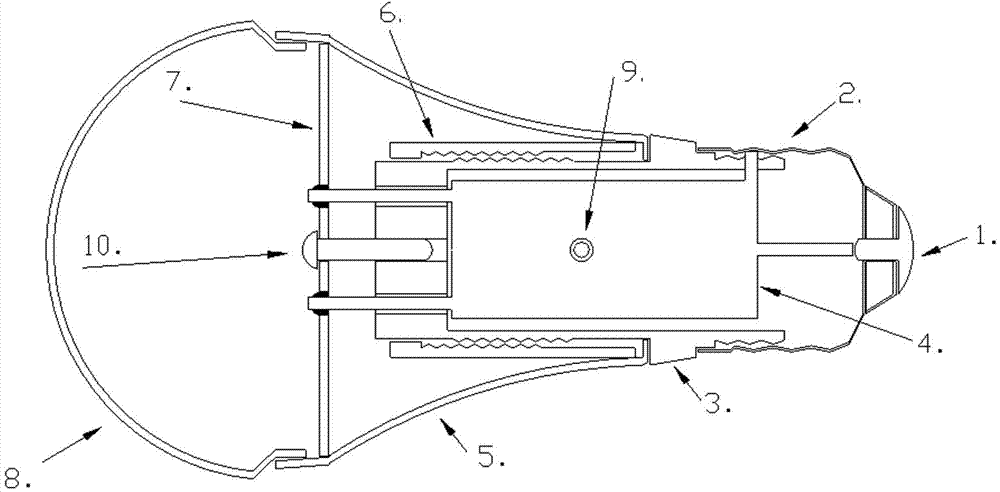

[0040] Example 2: see figure 2 , The two sets of joints on the upper side of the PCB drive assembly 4 are arranged symmetrically along the center line of the PCB drive assembly 4. When the lamp holder 2 adopts the E14, E26, E27 or E40 model, the back of the insulating housing 3 is provided with threads that match the threads of the lamp holder 2 Protruding ring, one of the sets of connectors on the lower side of the PCB drive assembly 4 is arranged horizontally and connected to the power terminal 1 of the lamp holder 2, and the other set of connectors is vertically penetrated in the threaded convex ring of the insulating housing 3 and connected to the lamp holder 2 The metal parts are locked and connected to realize electrical conduction.

Embodiment 3

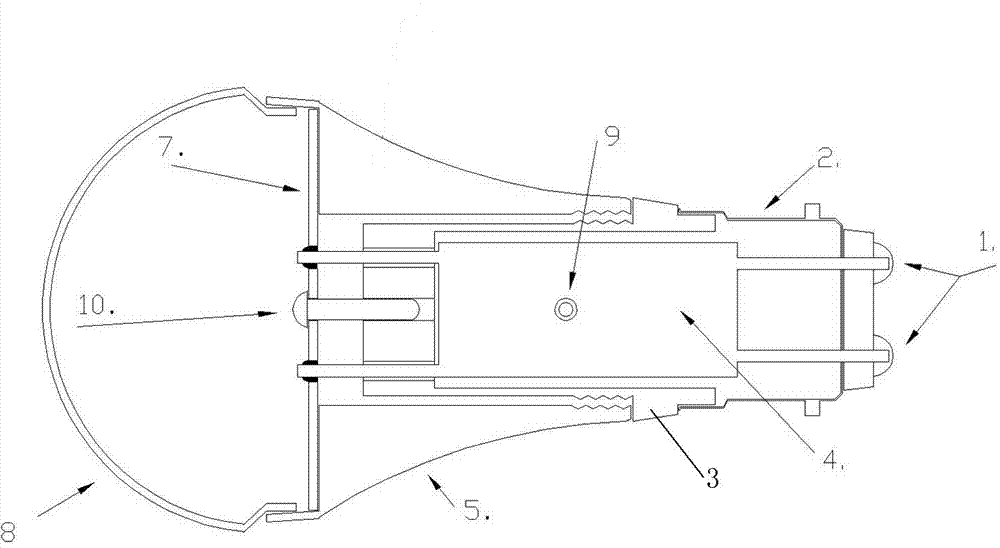

[0041] Embodiment 3: When the above-mentioned lamp holder 2 adopts the E14, E26, E27 or E40 model, the rear of the insulating housing 3 is provided with a threaded boss ring that matches with the lamp holder 2, and one set of joints on the lower side of the PCB drive assembly 4 is horizontal Set and connected with the power terminal 1 of the lamp holder 2, another set of joints is inserted in the threaded convex ring of the insulating housing 3 and wound on the threaded convex ring. The threaded convex ring of the insulating housing 3 is connected to the lamp holder 2. The metal parts are locked and connected to realize electrical conduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com