Method and system for determining effective air quantity

A method for determining air volume and a technology for determining effective air volume, which can solve problems such as accelerating sintering speed, wasting electric energy and heat energy, and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

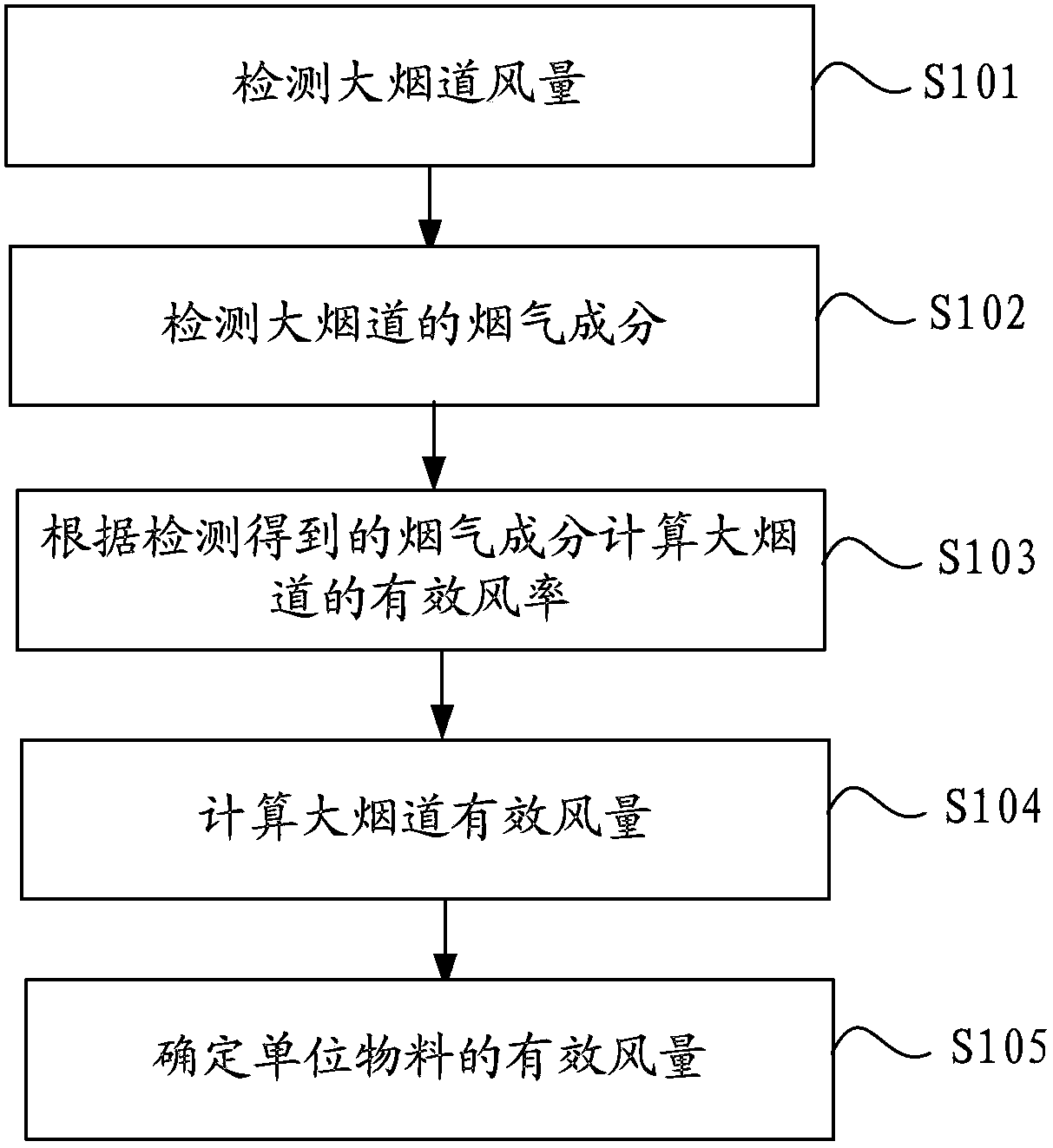

[0032] figure 1 It is a flow chart of the method for determining the effective air volume provided in Embodiment 1.

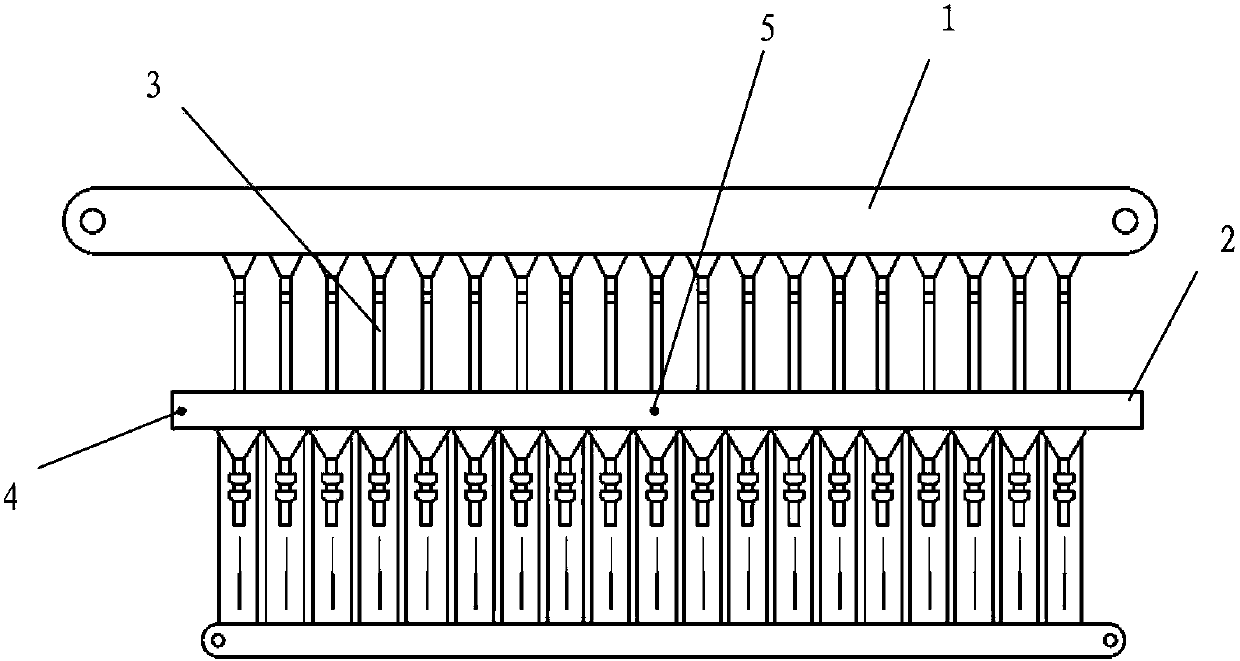

[0033] In this embodiment, an air volume detection device is directly installed in the large flue, and the air volume detection device is used to detect the air volume of the large flue. Such as figure 2 As shown in the figure, 1 is a trolley, 2 is a large flue, 3 is a bellows, and 4 is an air volume detection device, and the air volume detection device 4 is arranged in the large flue 2 .

[0034] Such as figure 1 As shown, first in step S101: detecting the large air volume of the flue. Next in step S102: detecting the smoke components of the large flue.

[0035] During the sintering process of the material layer, the oxygen in the air volume generated by the main exhaust fan will not be completely consumed, but only a part of the oxygen will participate in the sintering reaction. Therefore, the oxygen consumption of the material during the sintering proce...

Embodiment 2

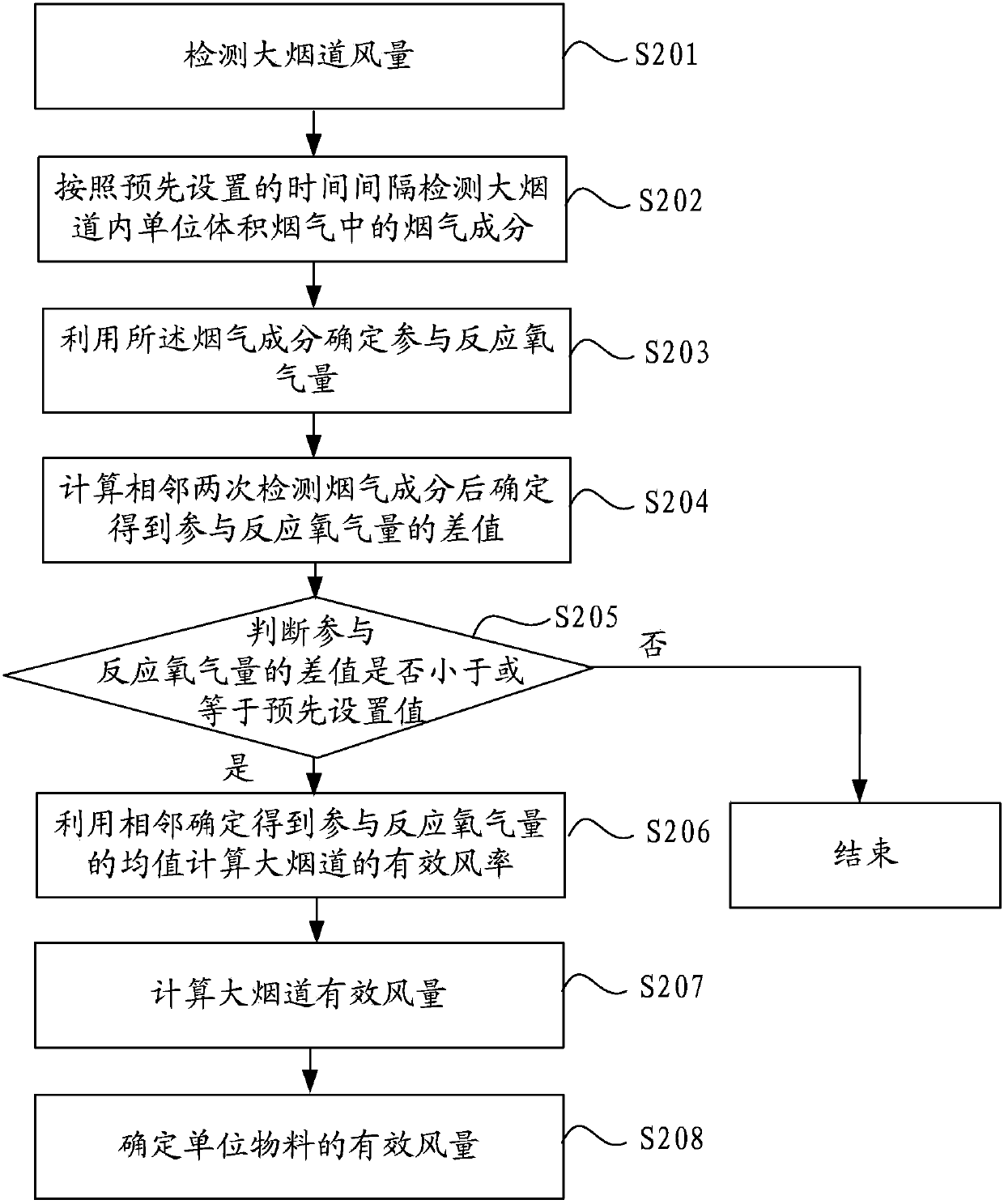

[0056] image 3 It is a flow chart of the method for determining the effective air volume provided in the second embodiment.

[0057] according to image 3 , the method is first at S201: detecting the air volume of the large flue, and then at S202: detecting the smoke components in the unit volume of smoke in the large flue at a preset time interval.

[0058] In this embodiment, the flue gas component in the flue gas per unit volume in the large flue is O in the flue gas per unit volume 2 , CO, CO 2 , N 2 , NO, NO 2 content. When detecting the flue gas composition of the large flue, the flue gas composition of the large flue is detected according to the preset time interval, and the detection of the system load stability can also be realized. When the flue gas composition of the large flue detected according to the time interval changes greatly, it indicates that the system load stability is poor, or there is a device failure in the system. If the system load stability ...

Embodiment 3

[0072] Figure 4 It is a flowchart of a method for determining an effective air volume provided in Embodiment 3.

[0073] like Figure 4 As shown, the method includes:

[0074] S301: Detecting a large flue air volume.

[0075] S302: Detect the smoke components of the large flue.

[0076] S303: Calculate the effective wind rate of the large flue according to the detected smoke components.

[0077] S304: Calculate the effective air volume of the large flue.

[0078] In this embodiment of the present application, steps S301-S304 are equivalent to steps S101-S104 in Embodiment 1. For detailed descriptions of steps S301-S303, please refer to the description of steps S101-S104 in Embodiment 1 above, which will not be repeated here.

[0079] S305: Calculate the volume of the material on the trolley.

[0080] Referring to the description in the above step S104, it can be seen that the effective air volume Q of the large flue 有效 It is the effective air volume of the material roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com