Coal body adsorption and desorption gas process deformation test device

A deformation test, adsorption and desorption technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring devices, instruments, etc., can solve problems such as constraints, experimental conditions that cannot meet the requirements, and cannot be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

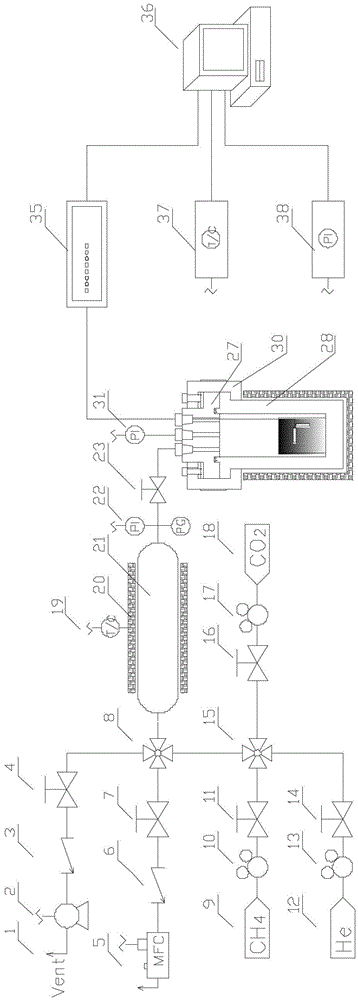

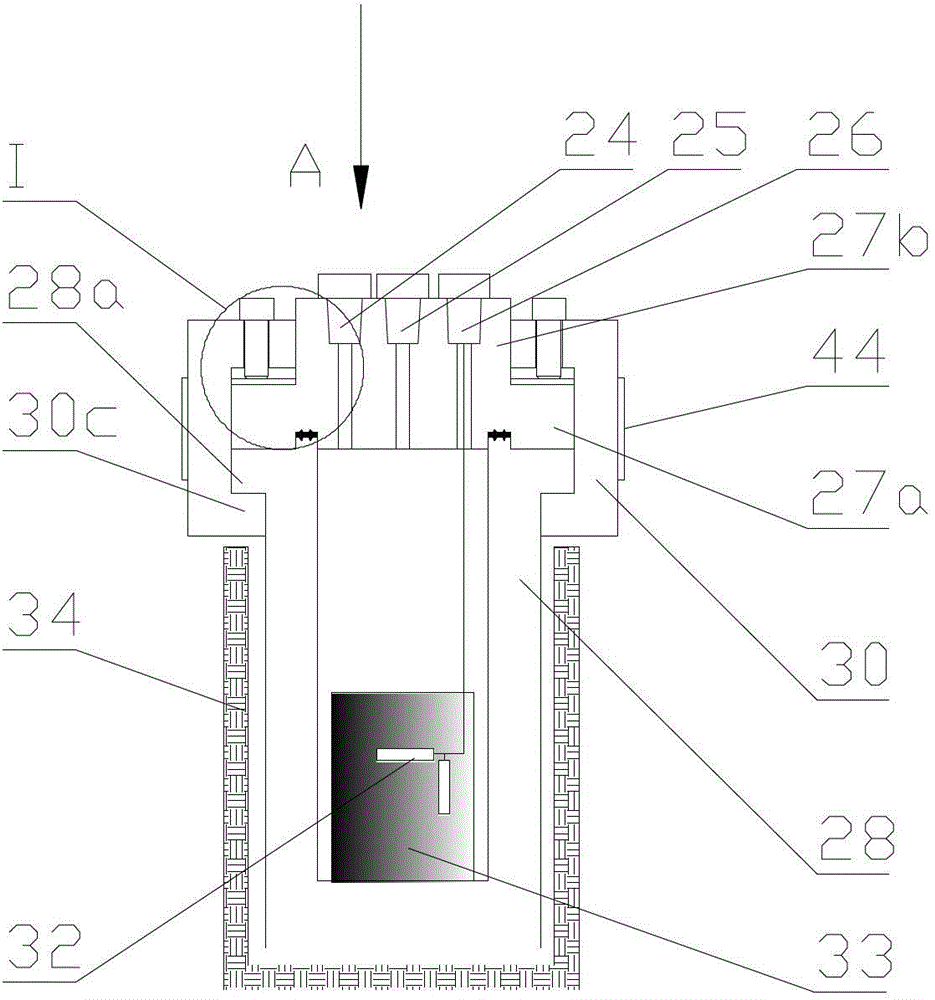

[0116] Such as Figure 1 to Figure 5 As shown, a coal adsorption and desorption test device includes a high-pressure adsorption and desorption tank, a deformation test system and a gas control system.

[0117] The deformation testing system includes a resistance strain gauge 32 and a resistance strain gauge 35 connected to each other. The resistance strain gauge 35 is connected to a comprehensive processing terminal 36 , and the comprehensive processing terminal 36 is connected to a pressure acquisition card 38 .

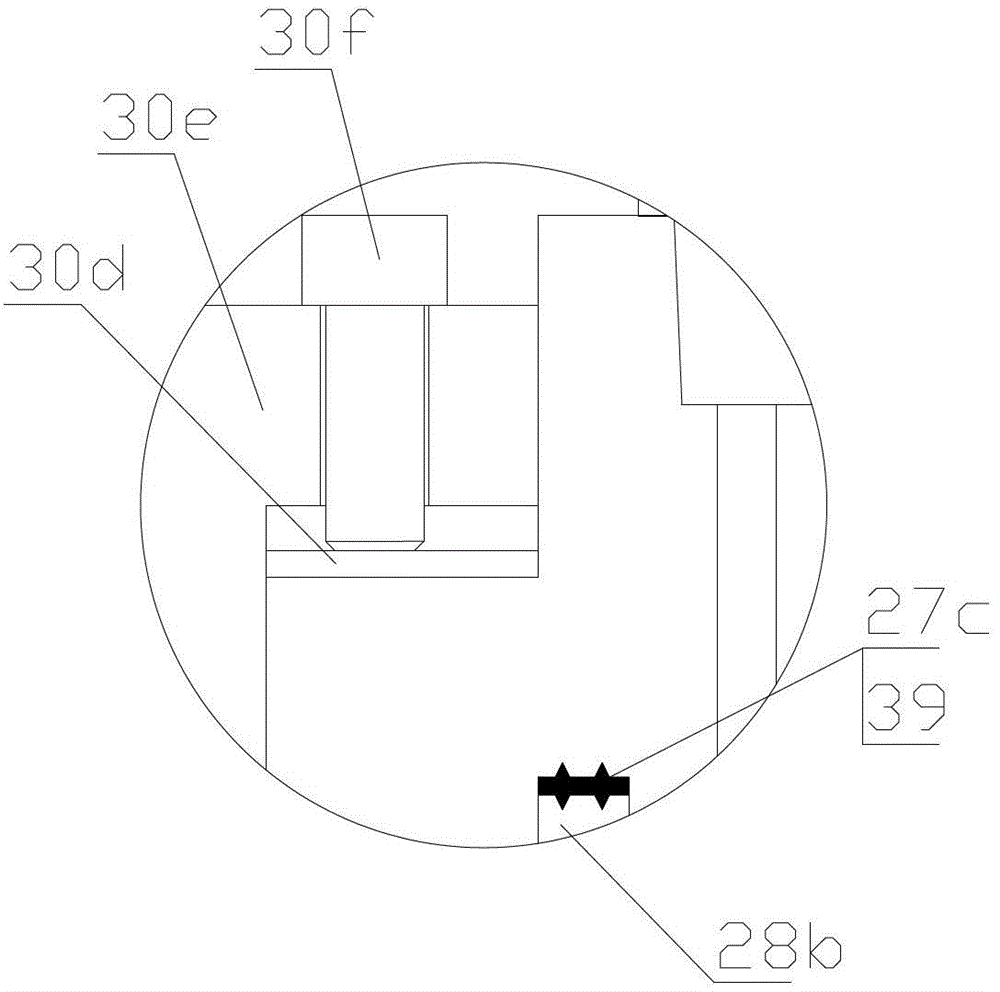

[0118] The high-pressure adsorption and desorption tank includes a tank body 28 and a top cover 27 arranged above the tank body 28. The top cover 27 is provided with a ring groove 27c on the side facing the tank body 28, and the tank body 28 is provided with an axial flange that cooperates with the ring groove 27c. 28b, a gasket 39 is provided on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com