Design method of buried heat exchange system

A technology of heat exchange system and design method, which is applied in the field of design of buried heat exchange system, can solve the problems of increasing energy consumption and the failure of the system to achieve energy saving, and achieve the effects of improving rationality, facilitating design calculations, and simplifying design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

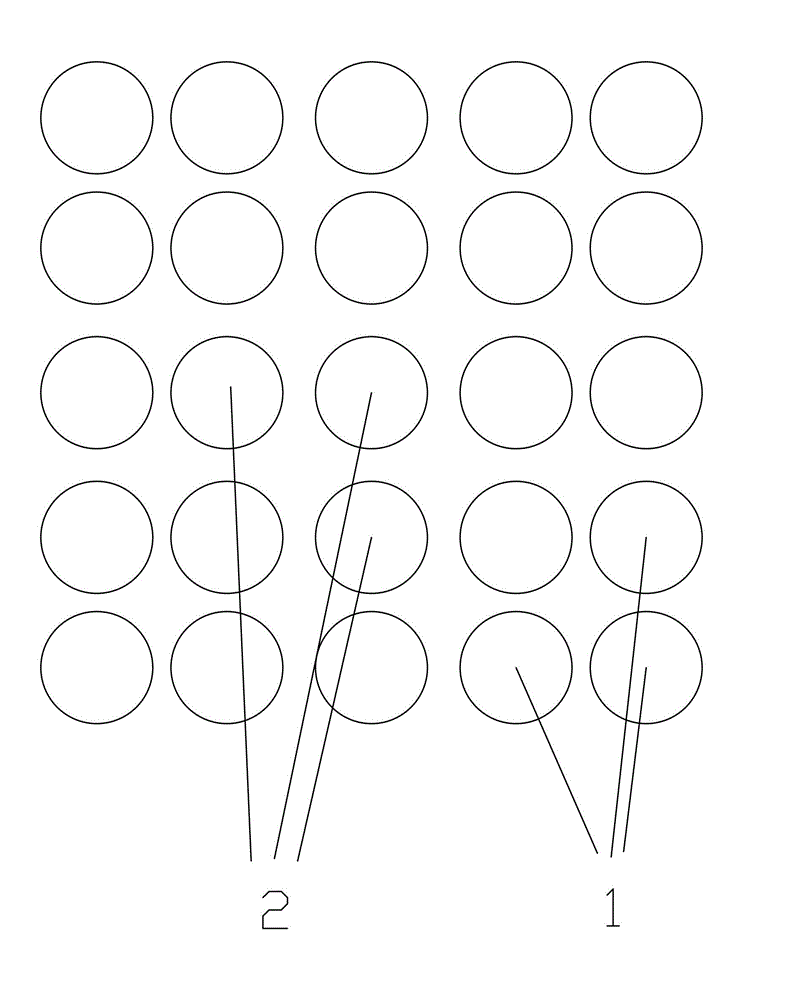

[0021] like figure 1 As shown, this embodiment provides a design method for a buried pipe ground source heat pump system, including the following steps:

[0022] First, the distance d of the buried pipe heat exchanger is calculated according to the buried area of the buried heat exchange system, and the distance between the outermost buried pipe 1 is 0.9 times the distance between the inner buried pipes 2 when buried. The distance d of the buried tube heat exchanger is calculated by the formula: d=L / 2(n+0.9), and d should be within 3~6m; where L is the buried area of the buried heat exchange system, and n is Buried thermal array row number.

[0023] Second, according to the layout distance d of the buried pipe heat exchanger and the thermal and physical parameters of the rock and soil, it is estimated by the following calculation formula:

[0024] Q'(d,c,λ)=-0.019d 2 cΔt-0.0031dc 2 Δt+0.12dcΔt+0.023d 2 Δt+0.011d 2 cλΔt-0.052dcλΔt-0.036d 2 λΔt-0.0083c 2 λΔt+0.3dλΔt+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com