Hydraulic System For Central Lubrication Of Engine Cylinders

A technology of engine cylinder and hydraulic system, applied in the direction of controlling lubricant pressure, piston fluid pressure measurement, electrical components, etc., can solve leakage and other problems, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

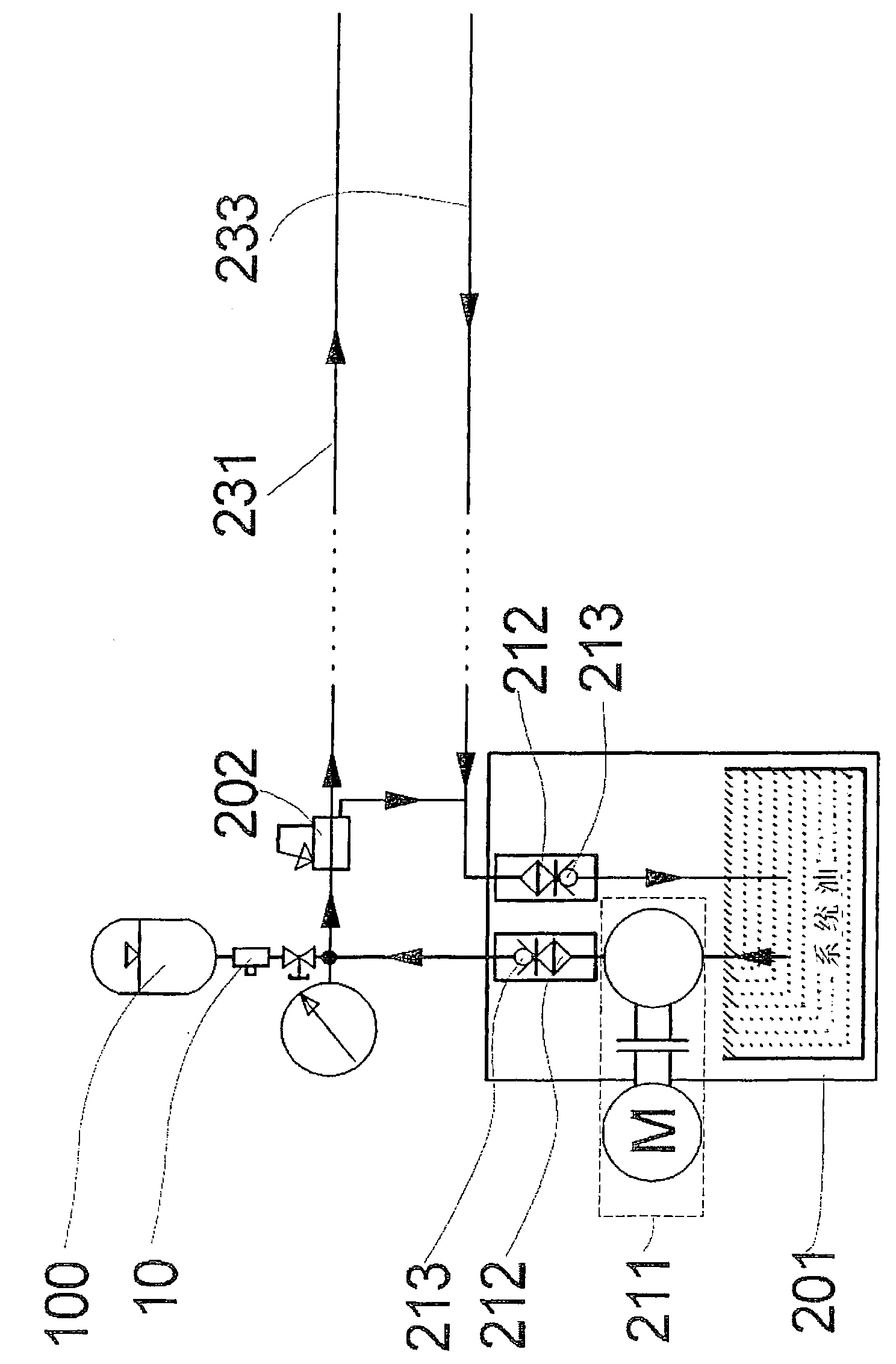

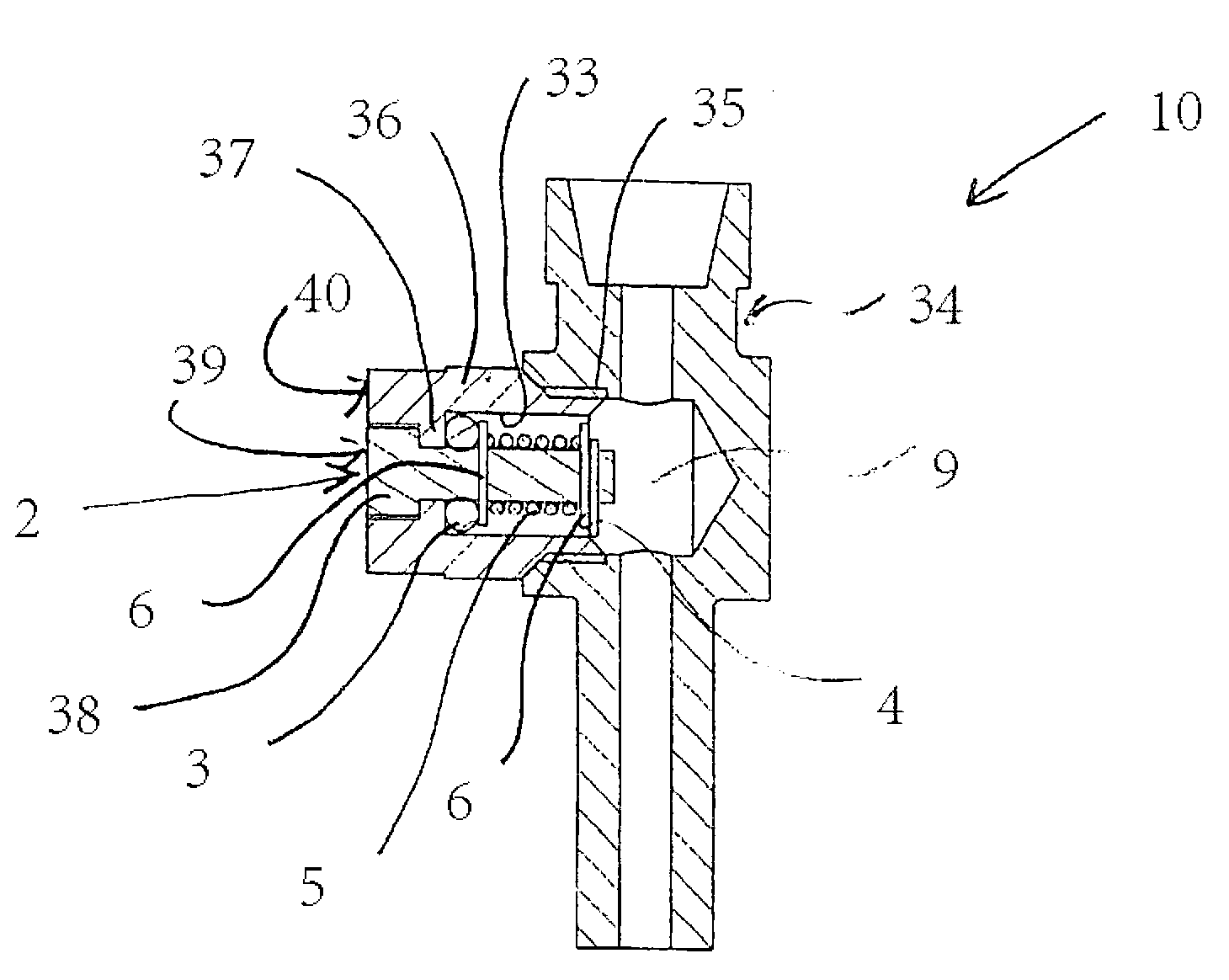

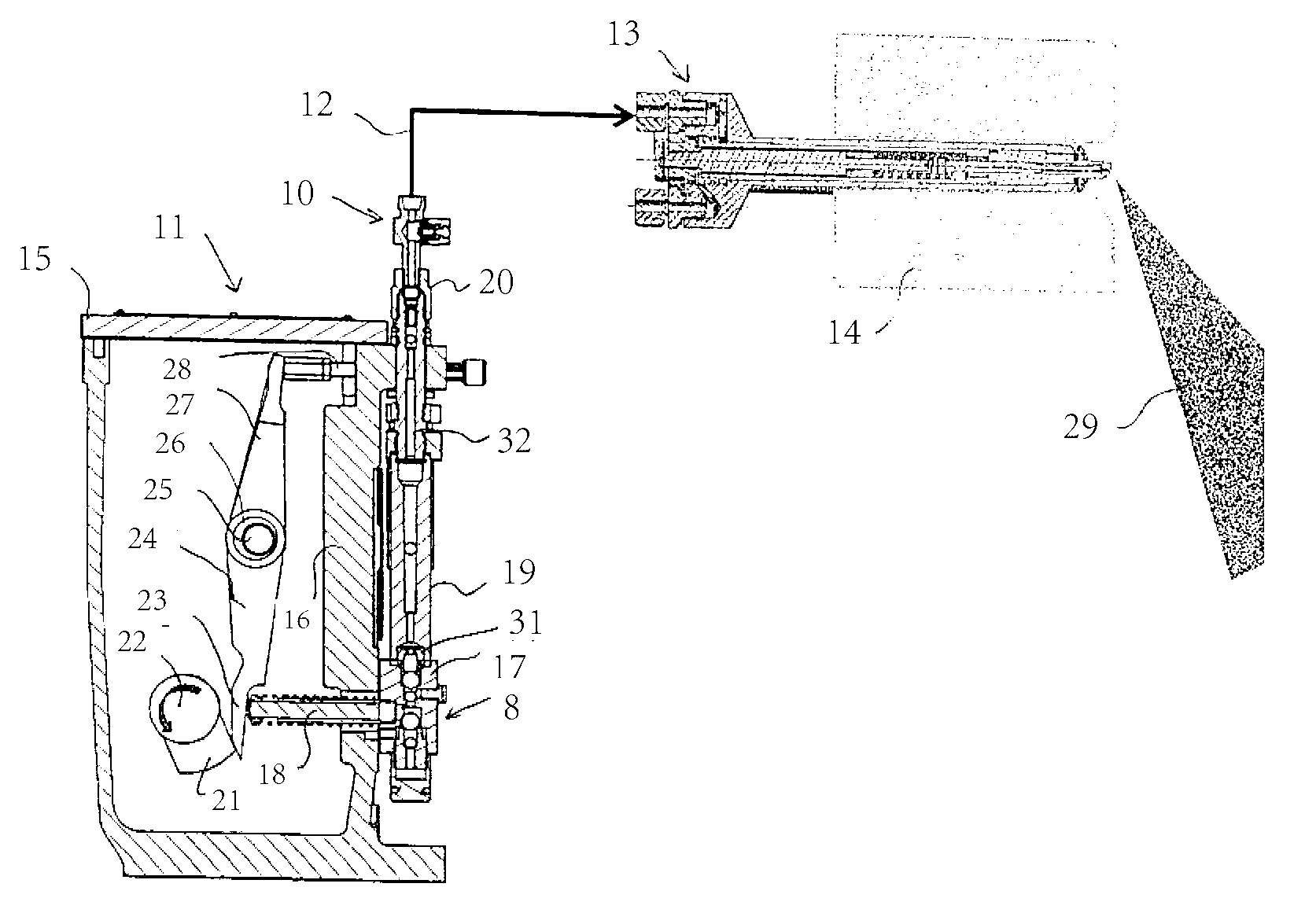

[0058] exist figure 1 , 2 The lubricating device 11 is illustrated in and 3 . The illustrated lubricating device has a box-shaped device housing 15 carrying on a front wall 16 a series of reciprocating pump assemblies 8, only one of which is shown here. The assembly has a valve housing 17 with a lower inlet for lubricating oil, a middle part for receiving the piston 18 protruding into the housing 15, and an upper outlet 31 for thus forming reciprocating pump. This outlet 31 is connected to the upper connection stud 20 through a flow indicator 19 and a channel 30 in a plate 32 . A plurality of connecting pipes originate from the entire row of these stubs and are distributed to the respective lubricating points of the cylinders of the engine, eg numbered 6-24.

[0059] The piston 18 is driven for pressurization by means of a drive tappet 21 on an all-through control shaft 22 which rotates synchronously with the crankshaft of the engine and rests on a bearing housing in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com