Intensive resource recovering plant factory

A plant-intensive technology, applied in the field of plant factories, can solve the problems of reducing cost, increasing yield, wasting cultivation area, and low utilization rate, avoiding waste of resources and affecting the environment, improving uneven distribution of concentration, and improving utilization rate of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

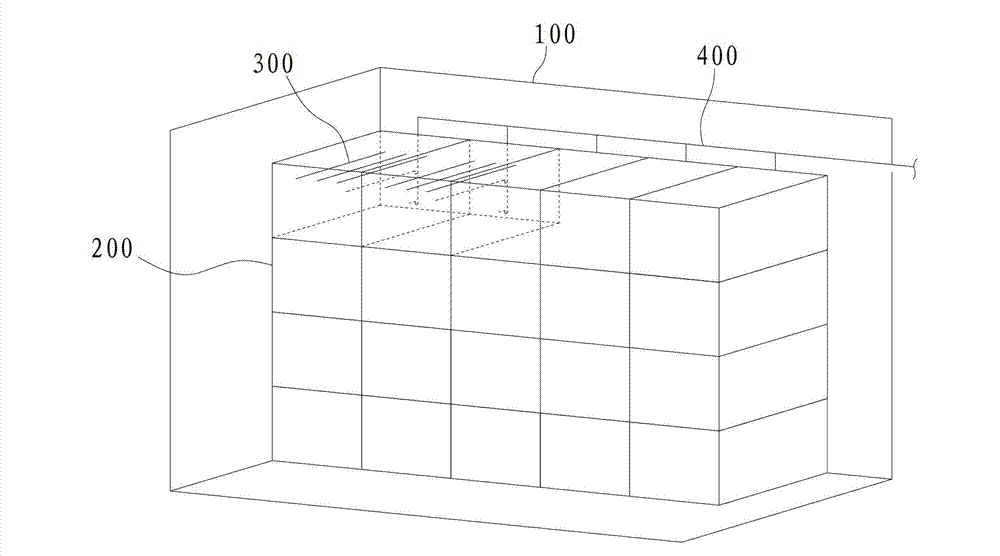

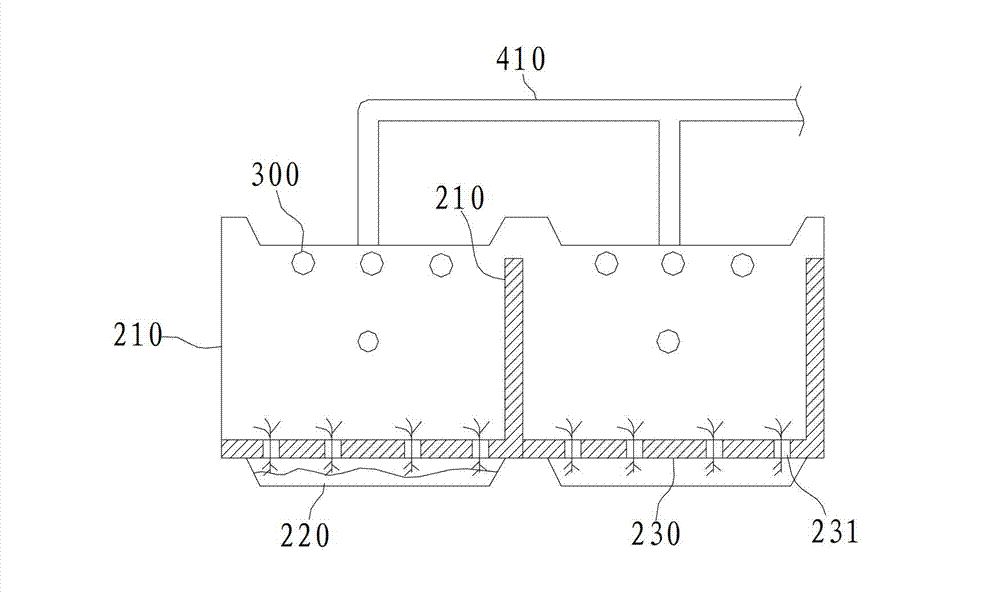

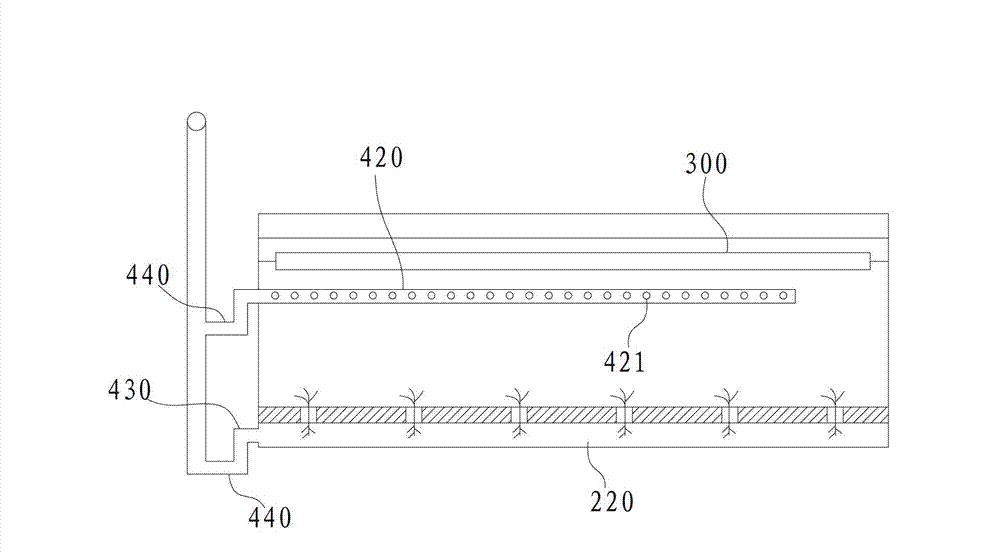

[0028] Such as figure 1 , 2 Shown in , 3 is a specific embodiment of the resource-intensive utilization type plant factory of the present invention, below in conjunction with accompanying drawing and embodiment, the specific embodiment of the present invention is described in further detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0029] figure 1 Shown is the three-dimensional structural diagram of the plant factory of the present invention. In order to express more clearly, three surrounding walls have been removed, and only some structural details such as plant cultivation units are shown. The plant factory includes an enclosure structure 100. Preferably, the inner surface of the enclosure structure 100 is set as a reflective surface to improve the light utilization rate. At the same time, compared with the existing conventional design, the enclosure structure 100 is surrounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com