Split-structure bottom surrounding sealing stripe of tobacco equipment

A split type and sealing technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of easily broken magnets, reduced sealing effect, and gaps on the bottom surface, and achieves the effect of beautiful overall structure, easy installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalents of the present invention Modifications in form all fall within the scope defined by the appended claims of this application.

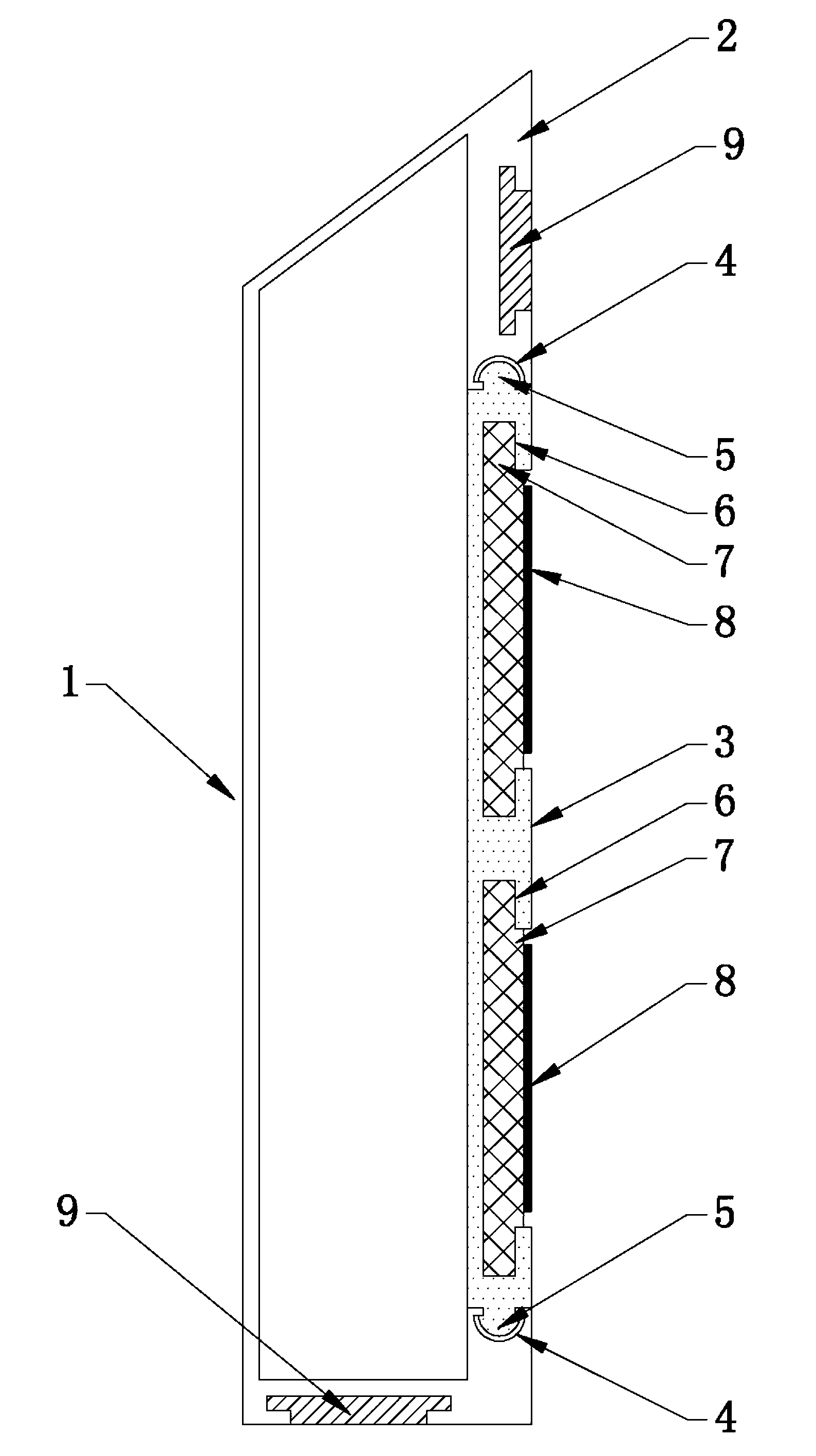

[0016] like figure 1 Shown: a split-type bottom sealing strip for tobacco equipment. The sealing strip 1 includes a sealing strip shell 2 with an oblique top and a connecting block 3 movably connected to it. The sealing strip shell 2 is attached to the sealing strip 1. Recessed cavity structure with openings in the joint direction, the connecting block 3 is located at the opening of the cavity of the sealing strip shell 2 and connected with the corresponding groove 4 on the sealing stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com