Sterilization method for nozzle assembly of bidet

A body cleaner and nozzle technology, applied in the field of warm water body cleaners, can solve the problems of inability to hygienically manage the peripheral part of the nozzle assembly, inability to kill harmful bacteria, and no satisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

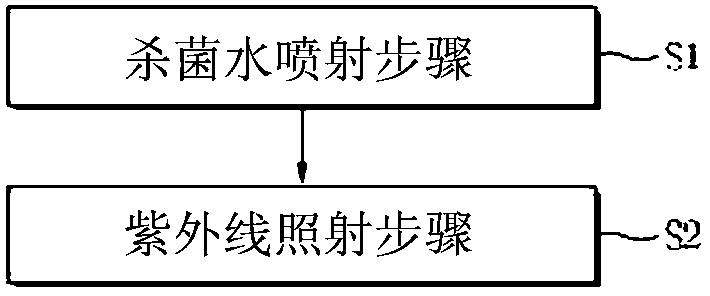

[0025] Such as figure 1 As shown, the method for sterilizing the nozzle assembly of the warm water bidet according to the present invention includes a sterilizing water spraying step S1 and an ultraviolet irradiation step S2.

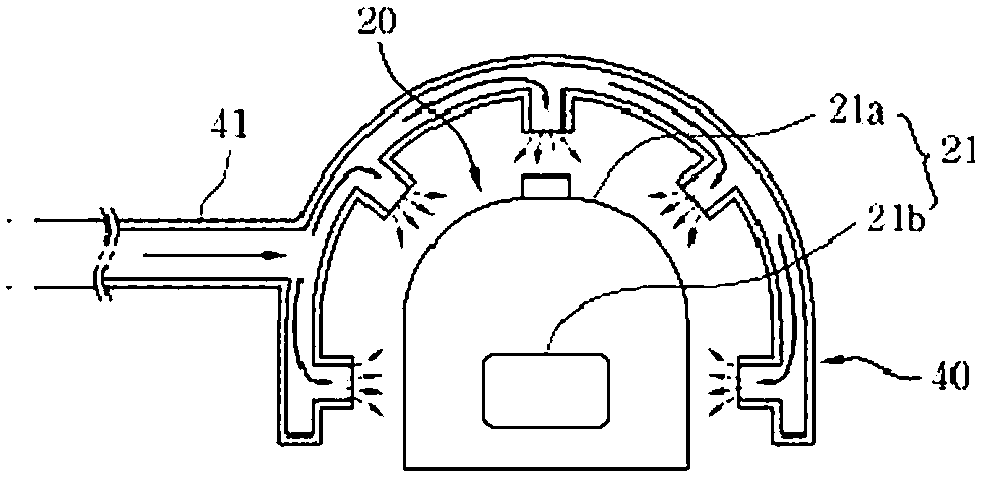

[0026] In the sterilizing water spraying step S1, the sterilizing water is sprayed to the nozzle assembly 20 and its peripheral parts through the self-cleaning nozzle 40 located at the front end of the nozzle assembly 20.

[0027] In such sterilizing water spraying step S1, sterilizing water is supplied from the sterilizing water generating unit 60 connected to the self-cleaning nozzle 40.

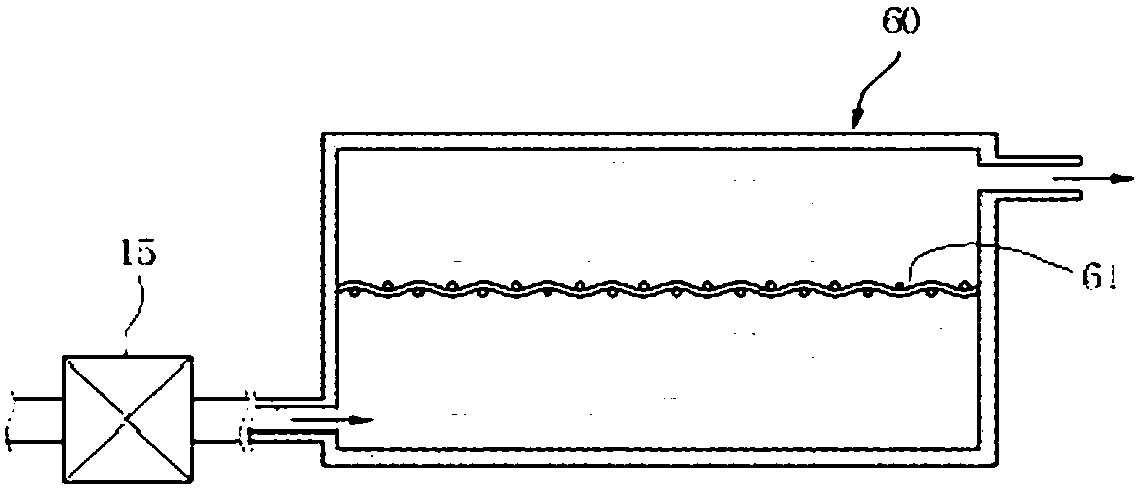

[0028] At this time, if image 3 As shown, preferably, the sterilizing water generation unit 60 uses grid 61 electrodes to apply a microcurrent to the cleaning water, thereby converting the cleaning water into oxygen active particles (O-, O 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com