Closed pulse dust collector and dust collection method thereof

A pulse dust collector and closed technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as inability to automatically and effectively remove dust, and achieve the effect of obvious dust removal effect and improved dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

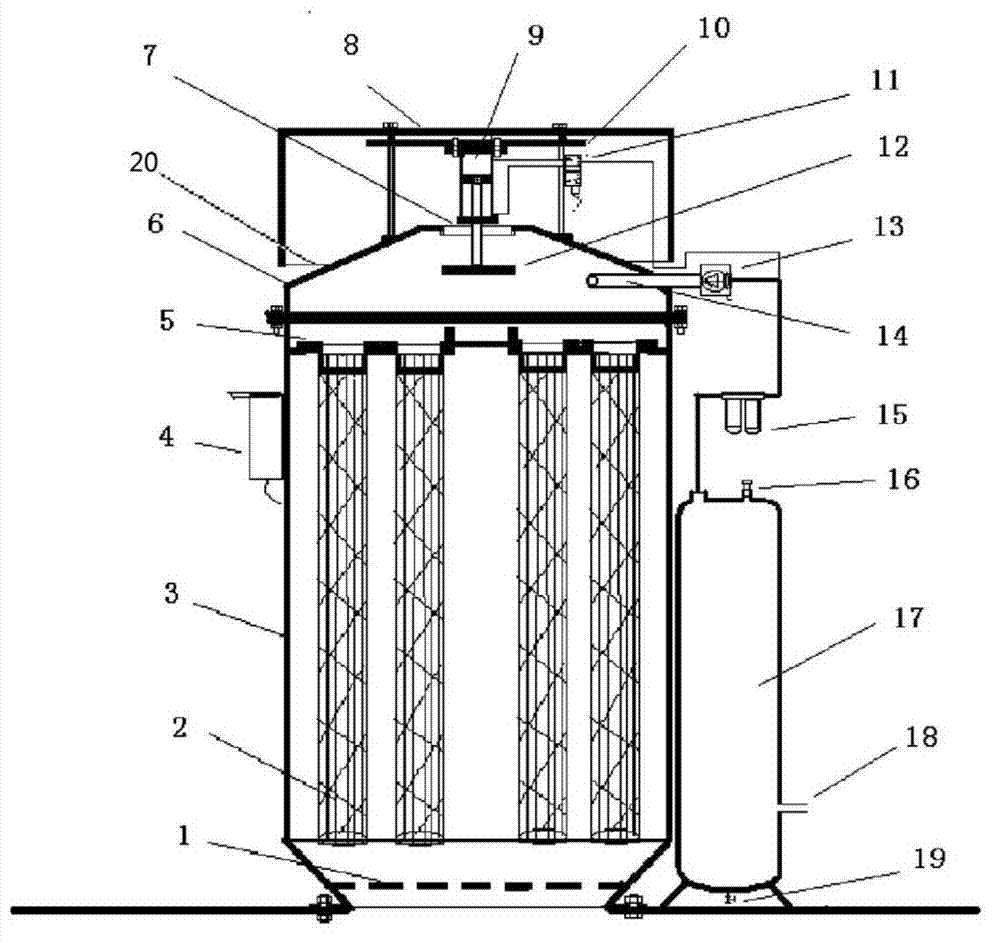

[0031] like figure 1 As shown, in the closed pulse dust collector in the present invention, the dust collector housing 3 is provided with a safety net 1 at the bottom of the dust collector housing 3, and a power control box 4 is provided at the side of the dust collector housing 3, and a dust removal filter element 2 The filter element fixing plate 5 is arranged inside the dust collector housing 3, the top position of the dust removal filter element 2 is provided with a sealing chamber cover 8, the dust removal filter element 2 is connected with the sealing chamber cover 6, and the top of the sealing chamber cover 6 is provided with an air outlet 7, and at the air outlet 7 is provided with a valve plate 12 that can be lifted up and down. The lifting of the valve plate 12 can control the opening or closing of the air outlet 7. The connecting rod of the valve plate 12 is connected with the cylinder 9. The electromagnetic pneumatic valve 11 controls the expansion and contraction o...

Embodiment 2

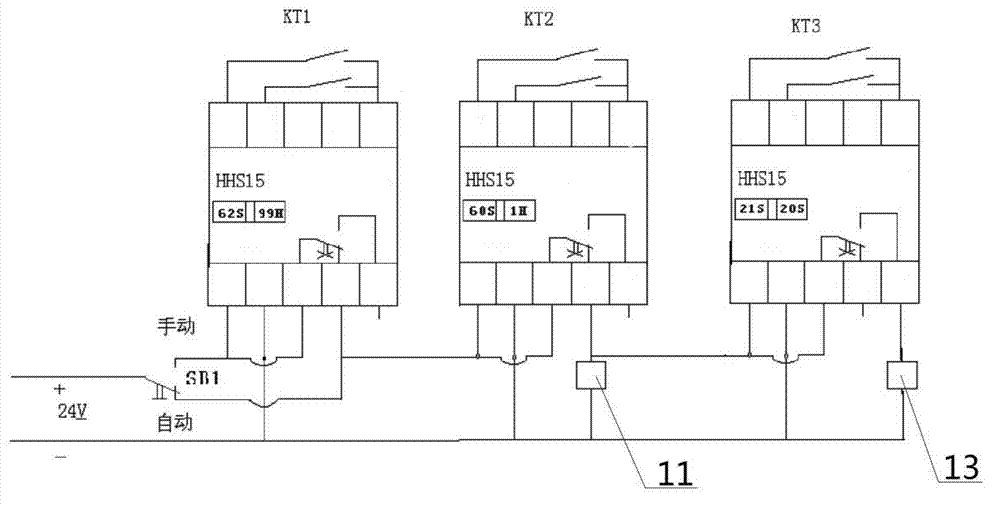

[0035] The difference from Embodiment 1 is that the diameter of the connecting air pipe between the air injection pipe 14, the air storage tank 17 and the air dryer 15 is 60mm, and the SB1 during dust removal is activated to the manual state, that is, after KT1 is energized, KT2 is connected. Pass through the electromagnetic pneumatic valve 11 to make the cylinder 9 push the valve plate 12 to close the air outlet 7 for a total of 80 seconds, and then after the valve plate 12 is closed for 15 seconds, the pulse pneumatic valve 13 will blow air for a total of 15 seconds, and then the valve plate 12 In the closed state for 50 seconds, the air pressure can be balanced in the sealed chamber cover 6. After the operation is completed, switch KT1 to the power-off state. At this time, KT2 and KT3 are also in the power-off state. The cleaning work is completed, and the above-mentioned cleaning work belongs to manual operation. The rest of the working principles are the same as in Embodi...

Embodiment 3

[0037] The difference from Example 1 is that the diameter of the connecting air pipe between the air injection pipe 14, the air storage tank 17 and the air dryer 15 is 50mm, and the dust removal method is that when SB1 is switched to the automatic gear, KT2 is energized Start the electromagnetic pneumatic valve 11 to push the cylinder 9 to pull up the valve plate 12 to close the air outlet 18 of the sealing chamber. Among them, the command issued by KT2 to the electromagnetic pneumatic valve 11 is to close the valve plate 12 for 70 seconds. When the valve plate 12 is closed, KT3 gets The instruction is to keep the air pressure stable after the valve 12 is closed for 19 seconds, and the pulse pneumatic valve 13 starts blowing, and the blowing time is 18 seconds, and the dust removal work is carried out on the dust removal filter element 2. After the blowing is finished, the valve plate 12 Keep it closed for 33 seconds, so that the air pressure in the sealing chamber cover 6 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com