Portable vortex and centrifugation integrated machine

An all-in-one, portable technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of large volume and slow start-up speed of tubular centrifuges, and achieve simple structure, convenient disassembly and replacement, and economical The effect of experimental space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

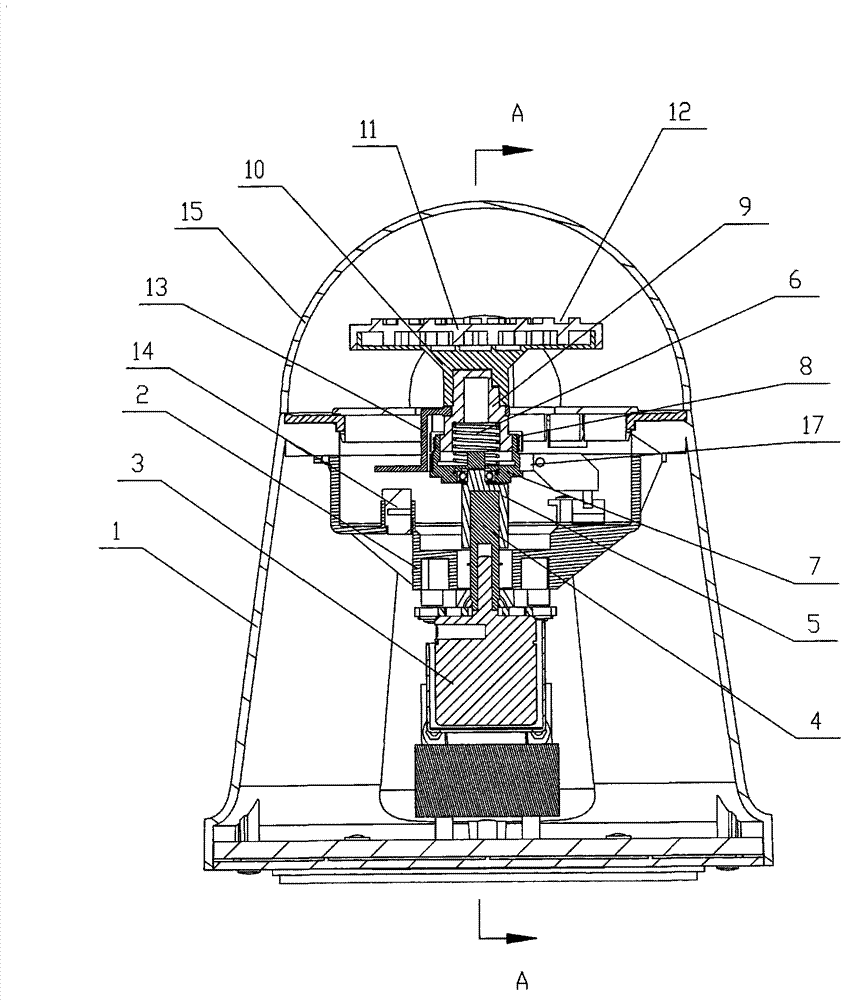

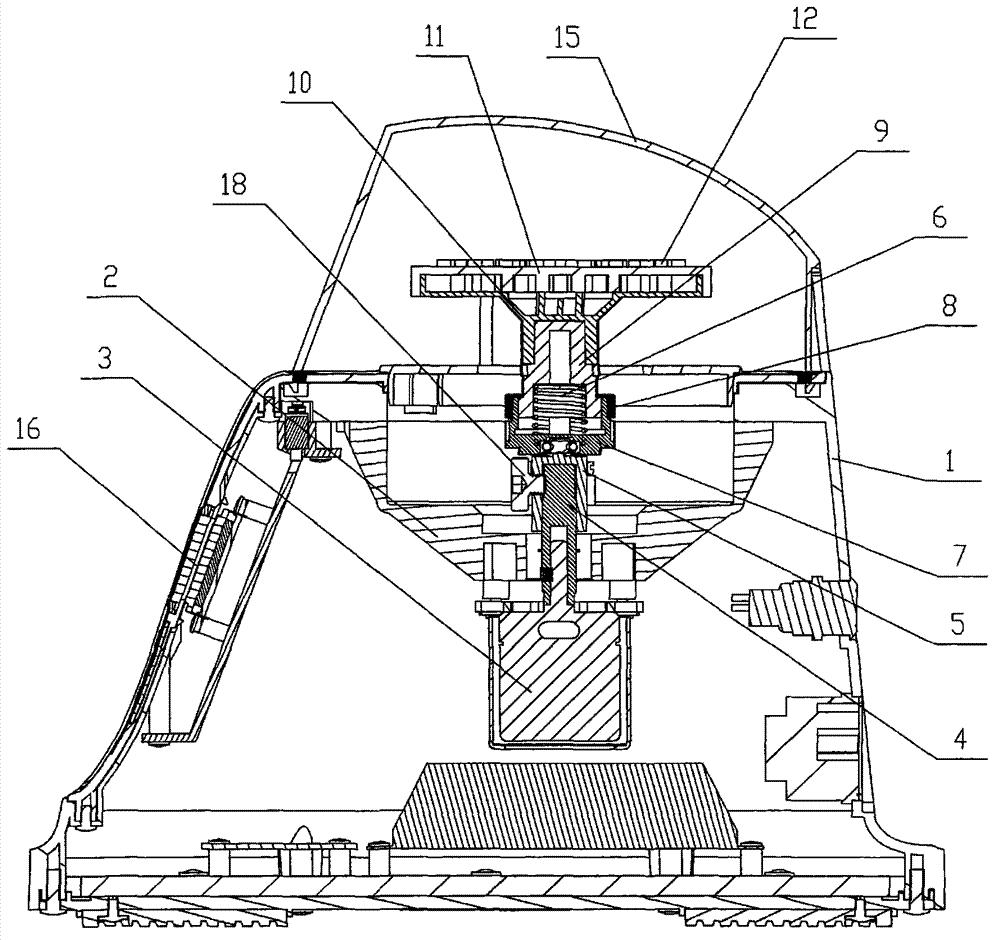

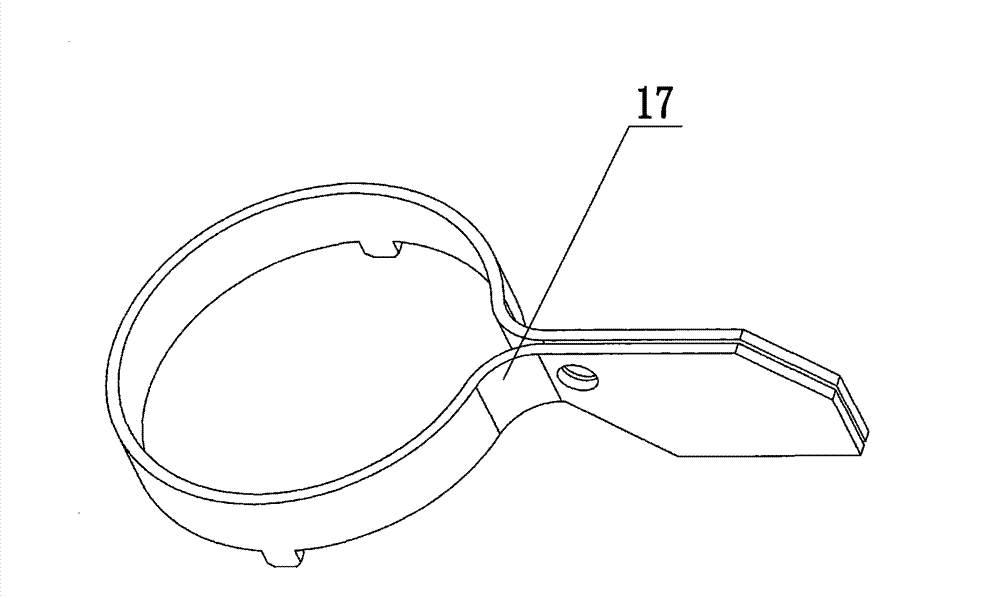

[0030] Such as figure 1 , 2 , 3, 4, 5, and 6, a portable vortex and centrifugal integrated machine, including a casing 1, a fixed seat 2, a motor 3, a connecting shaft 4, a vortex device, and a centrifugal device. The top of the casing 1 is provided with a guard The cover 15 is provided with an operation panel 16 on the side of the housing 1. The fixed base 2 is connected to the housing 1, the motor 3 is fixed on the fixed base 2, the motor 3 is a DC brushless motor, and the output shaft of the motor 3 is connected to a vortex device or a centrifugal device through a connecting shaft 4. The vortex device includes Scroll eccentric shaft 5, spring 6, scroll shaft seat 7, scroll shaft fixing cover 8, scroll shaft 9, scroll holder 10 and scroll plate 11, scroll eccentric shaft 5 and connecting shaft 4 are connected by screws 18 , The upper end of the scroll eccentric shaft 5 is connected to the scroll shaft seat 7 through a bearing, the scroll shaft 9 is connected to the scroll sha...

Embodiment 2

[0037] Such as Figure 7 As shown, the first embodiment is repeated, with the following differences: In this embodiment, the centrifuge disk 20 of the centrifuge device is a square centrifuge disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com