Spindle turning error source tracing method based on shaft center orbit manifold learning

A technology of axis trajectory and rotation error, which is applied to metal processing machinery parts, maintenance and safety accessories, measurement/indicating equipment, etc., to achieve the effect of improving service reliability, accuracy reliability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

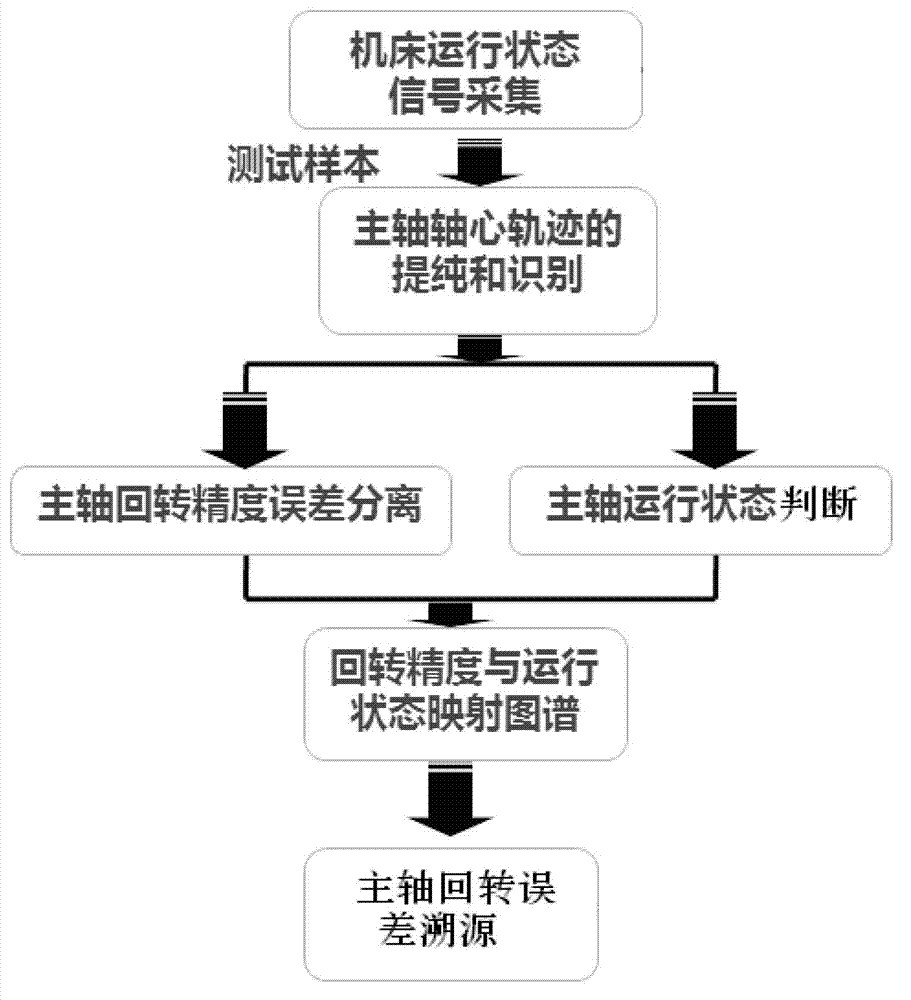

[0016] like figure 1 As shown, the present invention provides a method for tracing the source of the spindle rotation error based on the learning of the axis trajectory manifold, which includes the following steps:

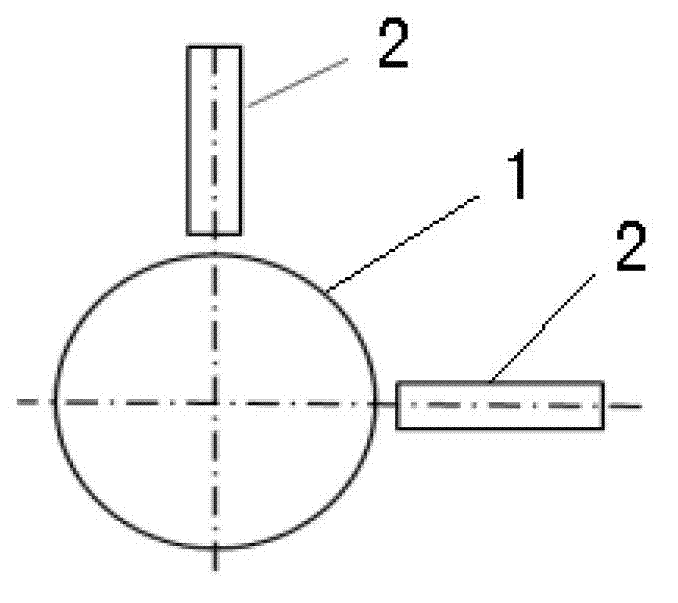

[0017] 1) Two eddy current sensors 2 are arranged at intervals in the outer circumferential direction of the main shaft 1, and the two eddy current sensors 2 are arranged staggered at 90° along the axis of the main shaft 1 (such as figure 2 As shown), the vibration signal of the main shaft 1 is collected by two eddy current sensors 2.

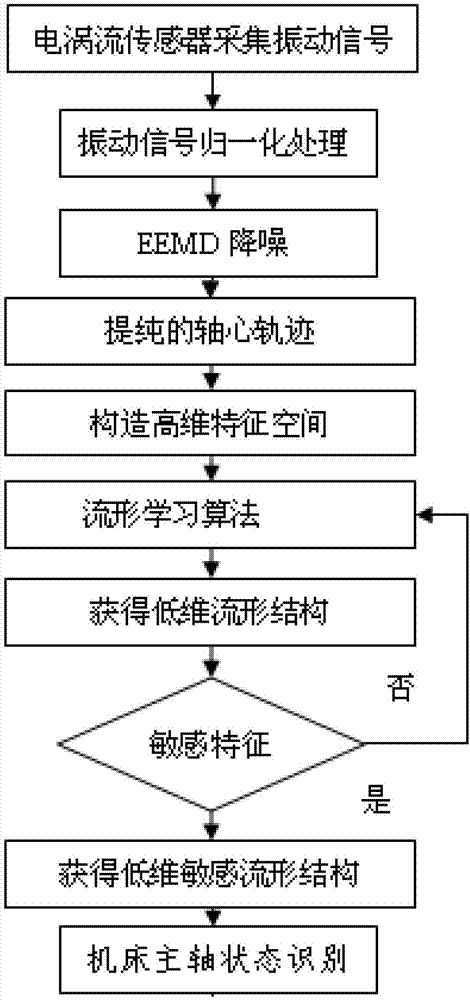

[0018] 2) Process the detected vibration signal of the spindle, and then judge the running state of the spindle 1 (such as image 3 shown), which includes the following steps:

[0019] (1) Mark the vibration signals measured by two eddy current sensors 2 arranged staggered at 90° as X and Y respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com