Automatic bamboo bar feeding structure

An automatic feeding, bamboo and wood technology, applied in conveyor objects, chutes, mechanical equipment, etc., can solve the problems of material jumping, low degree of automation, abnormal material, etc., and achieve stable material conveying, simple and firm structure, and degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

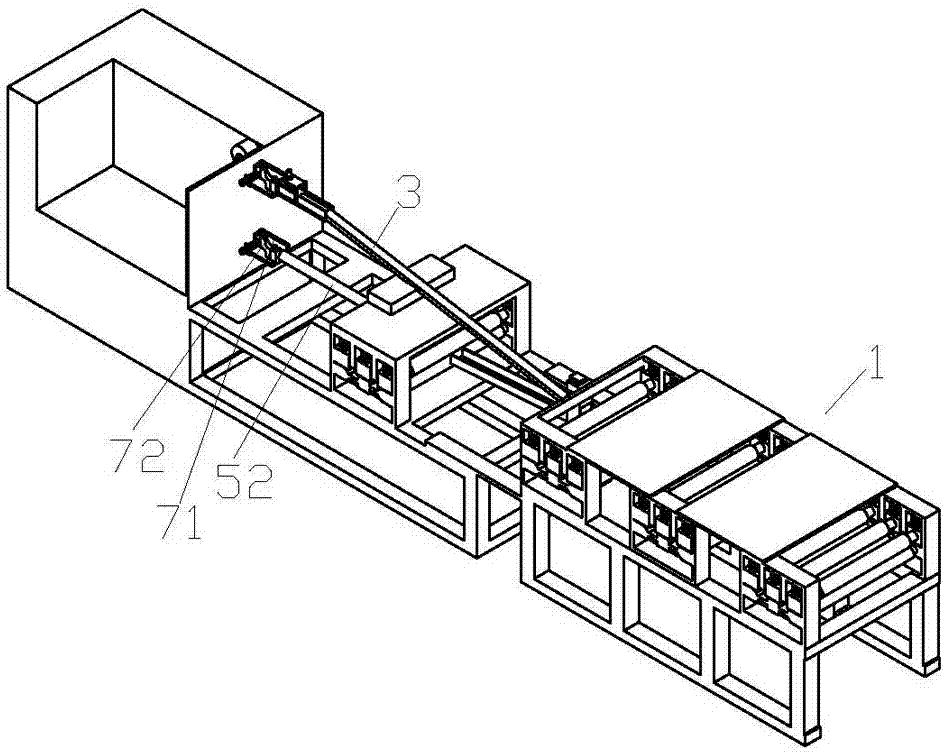

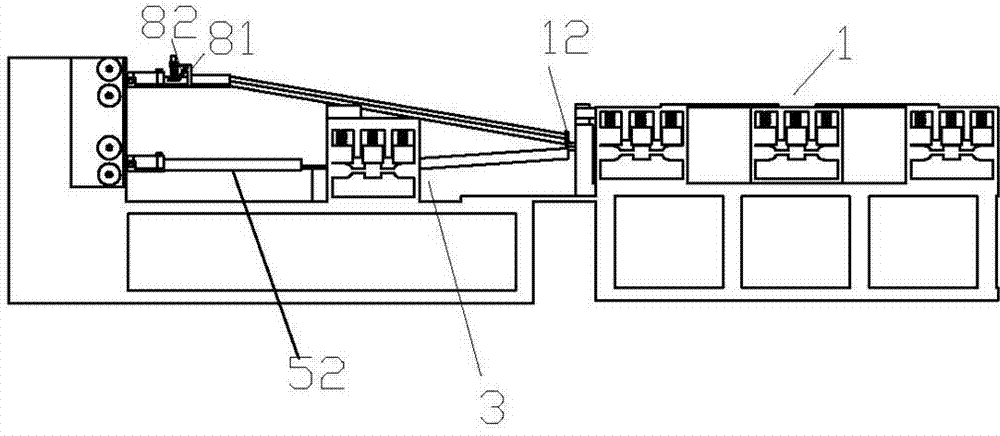

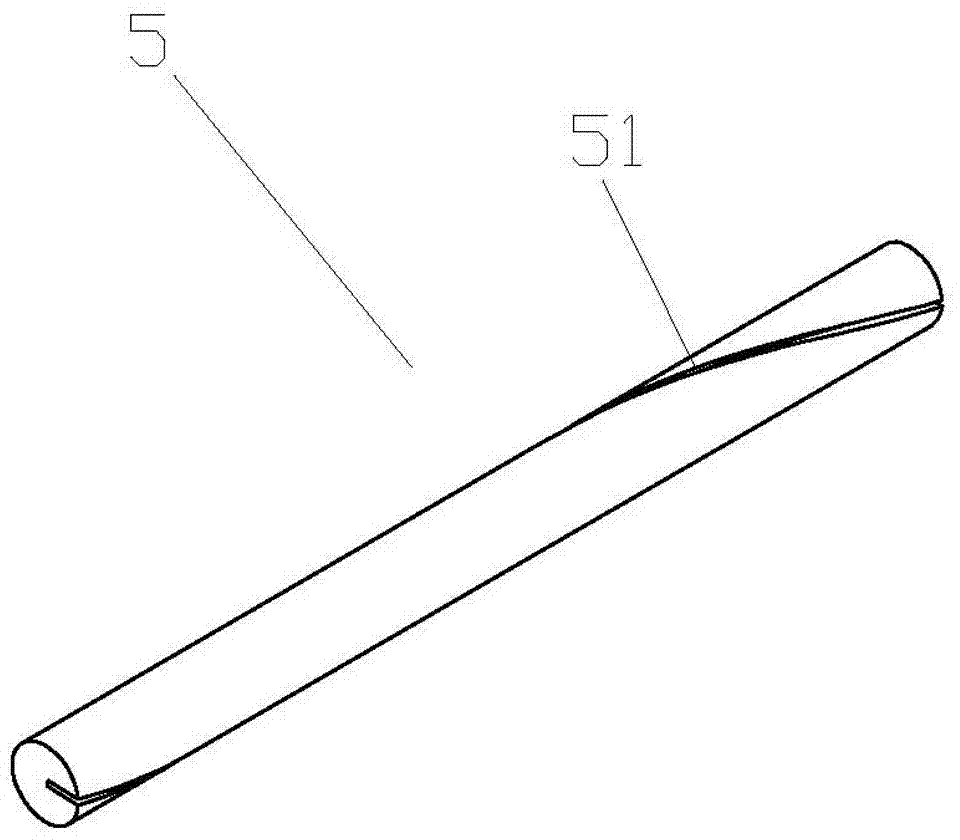

[0023] Example 1, such as figure 1 , 2 , shown in 3, 4, a kind of automatic feeding structure of bamboo strip, comprises the cutting device 1 that bamboo strip can be cut and conveyed, and cutting device 1 has inlet end and outlet end, and the outlet of cutting device 1 The end is provided with the fragmentation 12 that guides and conveys each bamboo strip after the cutting respectively, and the fragmentation device 1 can adopt a slicer, and each side that the fragmentation 12 separates the bamboo strip is respectively provided with a transmission device 3, and the transmission The device 3 has an inlet end and an outlet end. The inlet end of the transmission device 3 cooperates with the slice 12, and the outlet end of the transmission device 3 is provided with a surface treatment device that cooperates with it. The surface treatment device can be a wire drawing machine, and one piece can form two pieces. To cover the transmission system, two transmission devices 3 are ne...

Embodiment 2

[0024] Embodiment 2 differs from Embodiment 1 in that: the transfer devices 3 on both sides are equipped with turning structures and transfer devices.

Embodiment 3

[0025] The difference between Embodiment 3 and Embodiment 1 is that the outlet ends of the transmission devices 3 on both sides are provided with vertical limiting devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com