Intelligent back-cutting double-end vertical hole extending machine

An intelligent, vertical technology, used in glass cutting devices, glass manufacturing equipment, stone processing tools, etc., can solve the problems of long processing time, labor consumption, low production efficiency, etc. Improve work efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings:

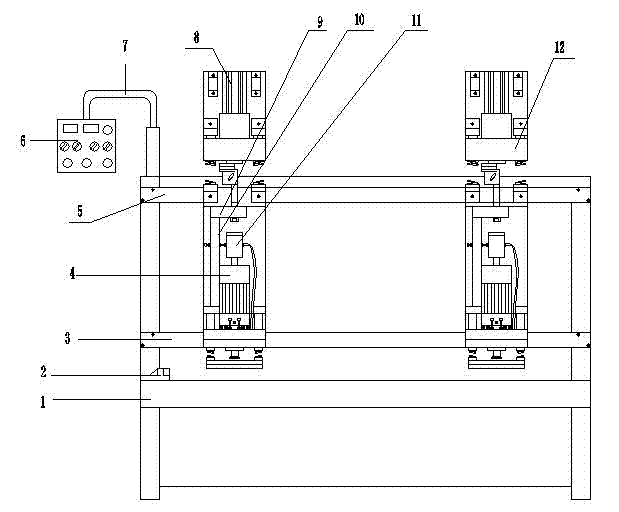

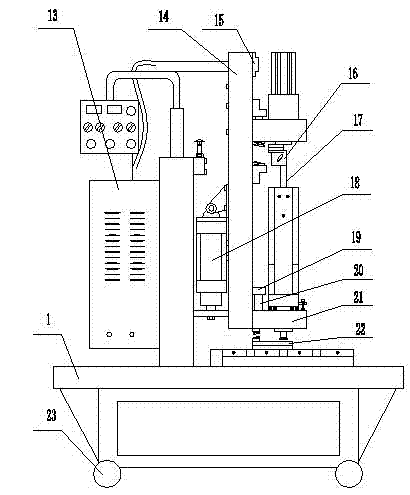

[0021] refer to figure 1 As shown, an intelligent rear-cut double-head vertical boring machine in Example 1 includes a bed 1, a frame 14, two groups of boring heads, and an electrical system, and universal rollers are set at the lower end of the bed 1 23. The frame 14 is set on the bed 1, the electrical box 13 is installed on the back of the frame 14, and the backing plate 2 is set on the frame 14. The backing plate 2 prevents the hole-boring machine head from colliding with the frame 14, and the top of the backing plate 2 is The transverse connecting rod 3 is arranged on the frame 14, and the boring machine head can reciprocate along the transverse connecting rod 3. The frame 14 is connected with the connecting rod 7, and the connecting rod 7 is connected with the control panel 6. The boring machine head passes through the machine head The plate 15 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com