Ink filling method of ink cartridge with double ink cavities

An ink cavity and ink filling technology, applied in printing and other directions, can solve the problems of poor ink filling, low product qualification rate, and inability to fill the ink cavity, and achieve the effect of good ink filling effect and good printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

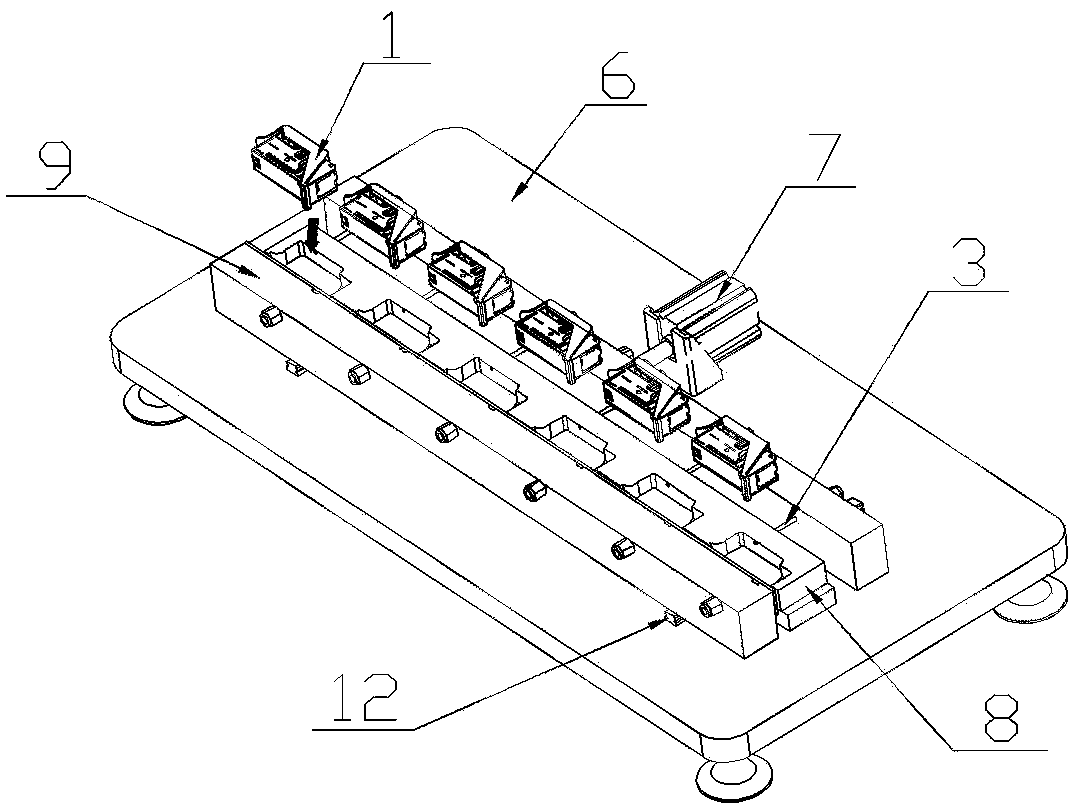

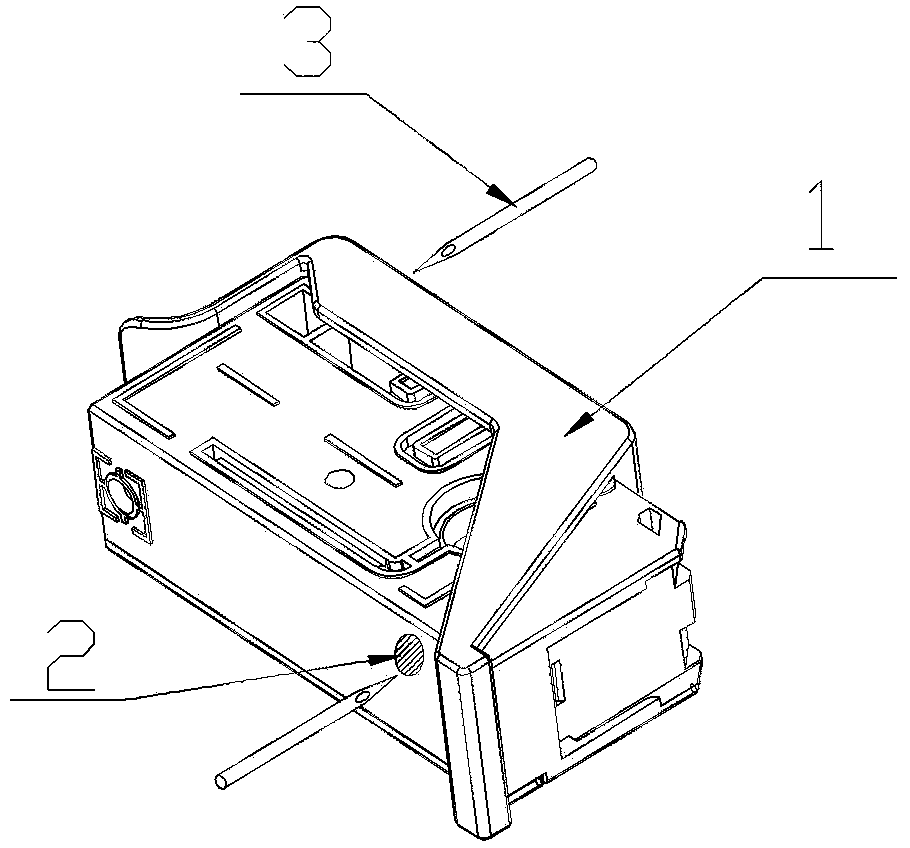

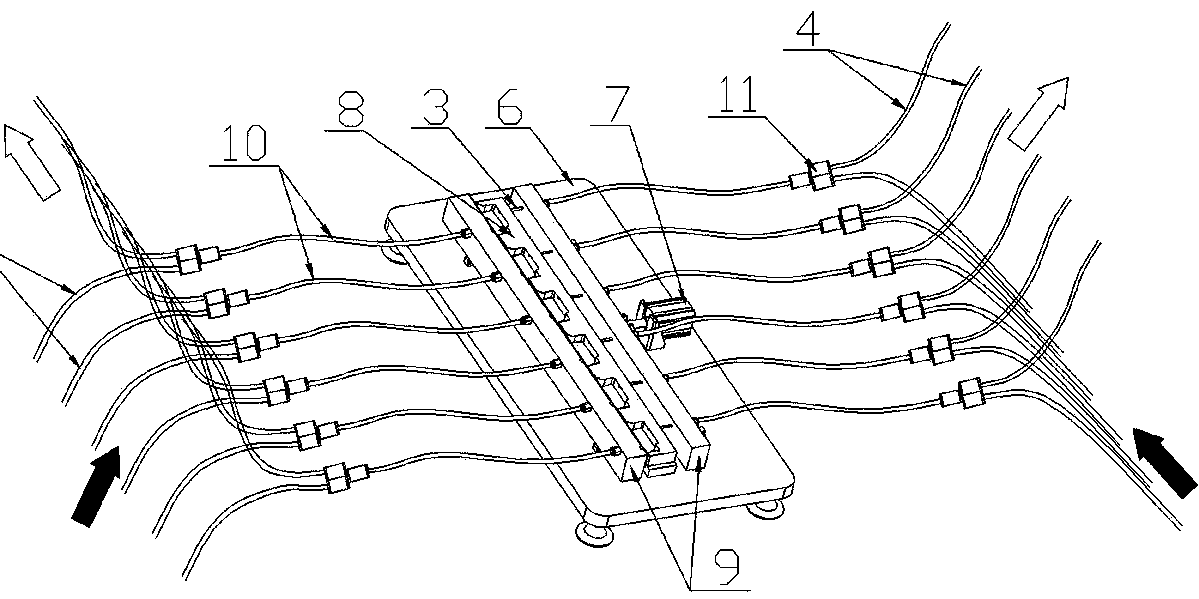

[0017] like figure 1 , figure 2 , image 3 As shown, the present invention relates to a method for filling ink with double ink chambers, which is used for filling ink with double ink chambers 1. The outer sides of the two ink chambers of the double ink chamber ink cartridge 1 are provided with ink filling ports. The ink filling port is blocked by silica gel 2, and the insides of the two ink chambers are connected. The ink filling method comprises the following steps:

[0018] (1) Two-way pumping: use the infusion needle 3, the connection end of the infusion needle 3 is connected to the vacuum pump through the air pipe 4, and the needle end of the infusion needle 3 is inserted into the ink chamber through the silica gel 2 , using the vacuum pump to simultaneously pump air to the two ink chambers until the vacuum values in the two ink chambers reach a set value;

[0019] (2) Two-way ink filling: After the above (1) step is completed, the connection end of the infusion need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com