Wharf steel silo loading flow monitoring system and method

A monitoring system and material flow technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of delayed delivery, pollution of the surrounding environment, flying ash and other problems, and achieve the effect of solving material blockage, reducing pollution and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

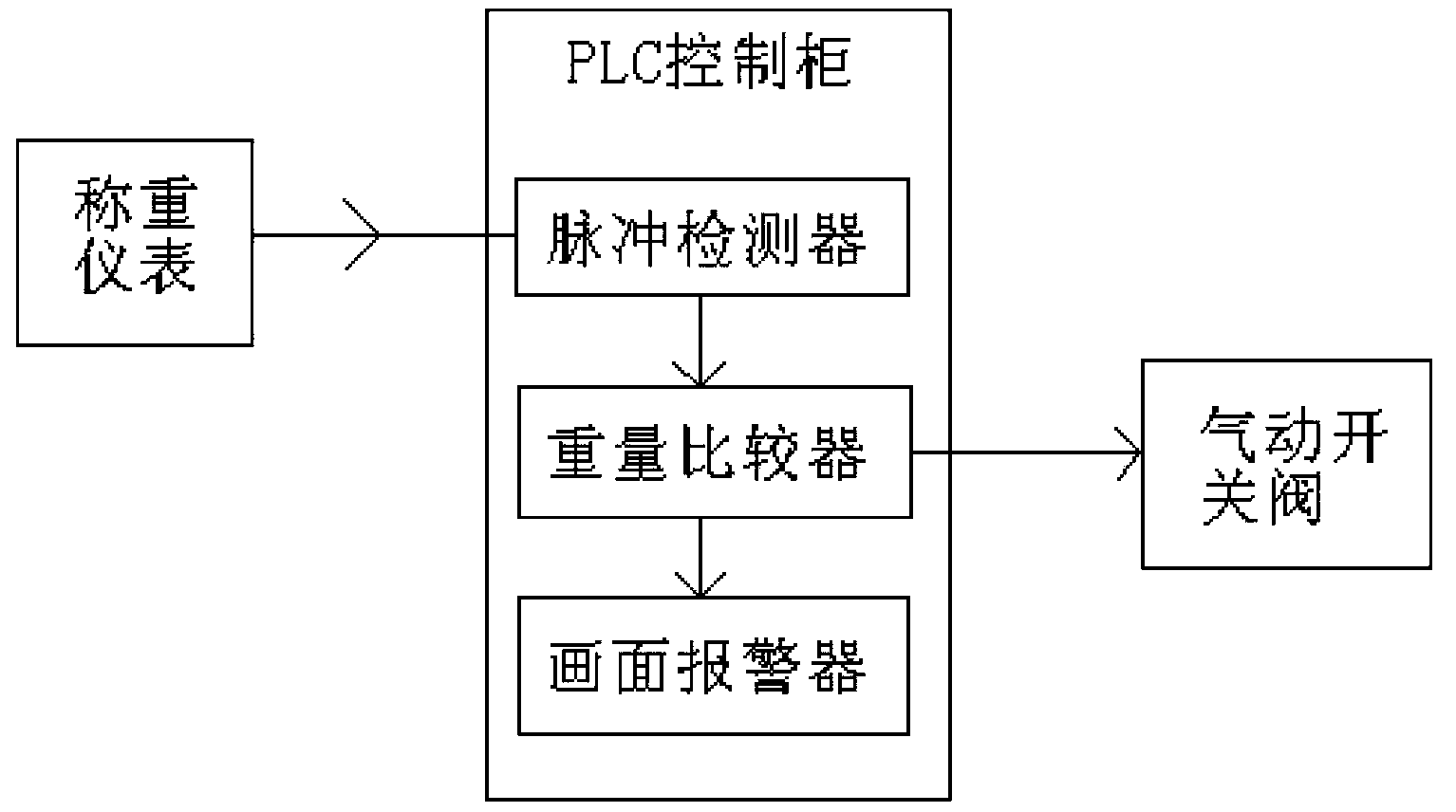

[0023] This embodiment provides a wharf steel silo feeding flow monitoring system, its structure schematic diagram is as follows figure 1 As shown, including weighing instrument, PLC control cabinet and pneumatic switch valve.

[0024] The weighing instrument is connected with the PLC control cabinet to monitor the mineral powder weighing signal stored in the steel warehouse, and convert the weighing signal into a 4~20 mA current signal and send it to the PLC control cabinet.

[0025] The PLC control cabinet is connected with the pneumatic on-off valve to control the closing of the pneumatic on-off valve and stop feeding.

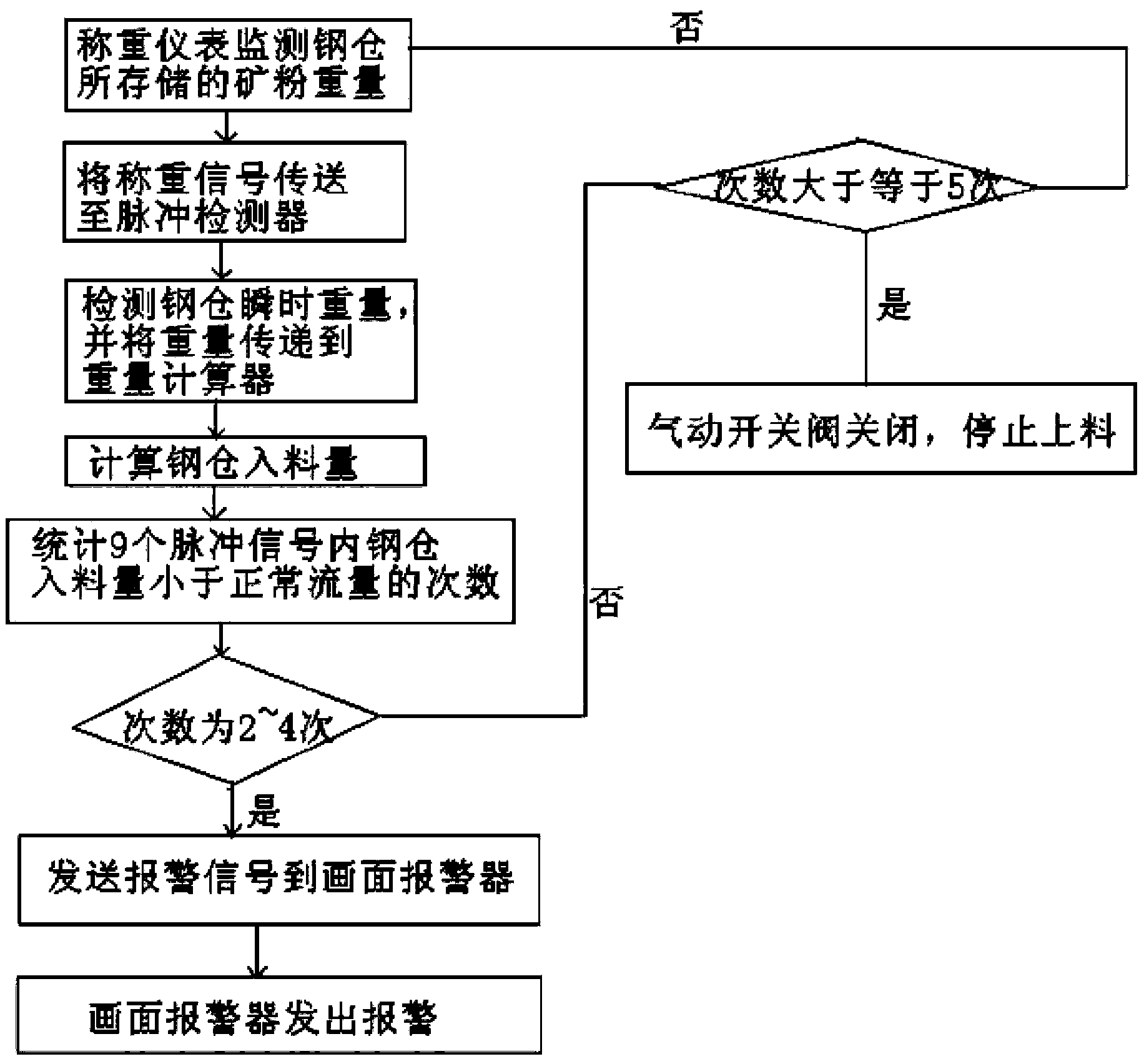

[0026] The PLC control cabinet includes a pulse detector, a weight comparator and a picture alarm. The pulse detector receives the 4-20 mA current signal transmitted by the weighing instrument to detect the instantaneous weight of the steel bin, and transmits the weight to the weight comparator; The weight comparator calculates the feeding amount of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com