Parabola-shaped material bending trough for molten glass feeding machine

A feeding machine and parabolic technology, applied in the direction of feeding trough, etc., can solve the problems of bottle body wrinkles, bottle wall thickness, uneven bottom thickness, difficulty in ensuring the stability of material drops, etc., to solve the problem of low yield and blanking Accelerated, well-directed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

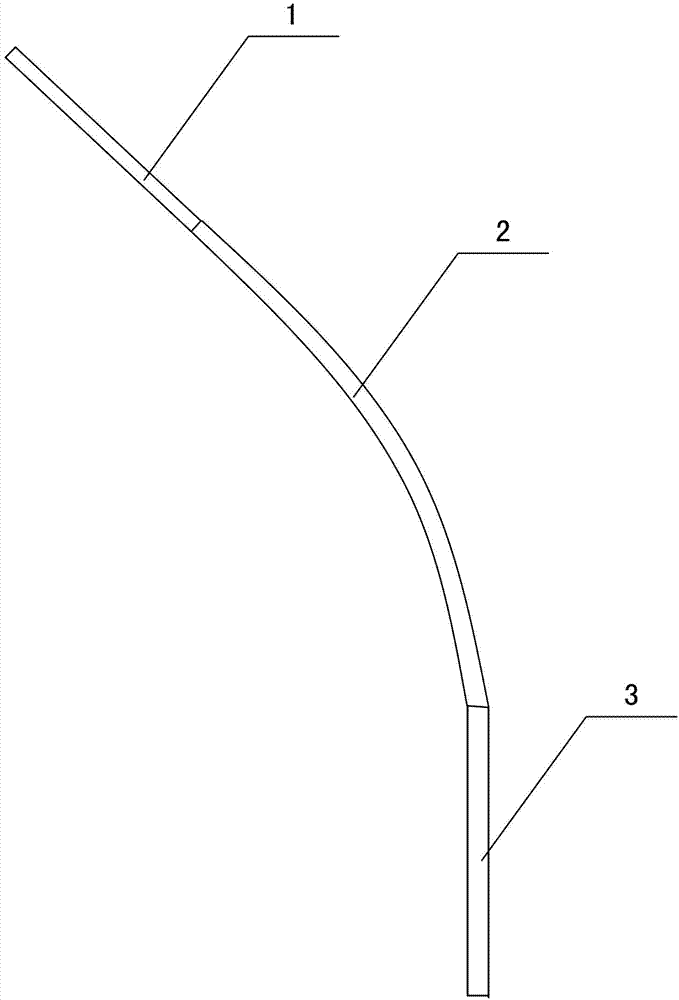

[0012] Such as figure 1 As shown, the trough is composed of the first tank body 1, the second tank body 2 and the third tank body 3 connected in sequence, wherein the first tank body 1 is obliquely linear, the second tank body 2 is parabolic, and the third tank body is The tank body 3 is vertically linear.

[0013] Due to the use of the parabolic second trough 2, the whole process of glass gob falling is guided, the speed of falling is accelerated, and it is stable, smooth and well oriented. after the situation. It completely solves the problem of low yield caused by unstable blanking during the production of small-scale products within 20g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com