Lignin serial coal water slurry dispersing agent and preparation method thereof

A lignin and dispersant technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of limited sulfonation degree, high requirements for production equipment and conditions, and high price, and achieve low product cost and low price , The effect of improving molecular quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A lignin-based coal-water slurry dispersant, characterized in that it comprises the following raw material components in parts by weight:

[0052] Alkali lignin 1000 parts

[0053] Polyethylene glycol 20 parts

[0054] Carboxylic acid 2 parts

[0055] 1 part concentrated sulfuric acid

[0056] Hydroquinone 0.1 parts

[0057] Acrylic 20 parts

[0058] Vinyl monomer 60 parts

[0059] Sodium sulfite 200 parts

[0060] Acetaldehyde solution 300 parts

[0061] 30 parts of oxidizing agent

[0062] 10 parts of reducing agent.

Embodiment 2

[0064] A lignin-based coal-water slurry dispersant, characterized in that it comprises the following raw material components in parts by weight:

[0065] Alkali lignin 1000 parts

[0066] Polyethylene glycol 50 parts

[0067] Carboxylic acid 10 parts

[0068] Concentrated sulfuric acid 5 parts

[0069] 1 part hydroquinone

[0070] Acrylic 60 parts

[0071] Vinyl monomer 150 parts

[0072] Sodium sulfite 400 parts

[0073] Acetaldehyde solution 500 parts

[0074] oxidizing agent 50 parts

[0075] 20 parts of reducing agent.

Embodiment 3

[0077] A lignin-based coal-water slurry dispersant, characterized in that it comprises the following raw material components in parts by weight:

[0078] Alkali lignin 1000 parts

[0079] Polyethylene glycol 35 parts

[0080] Carboxylic acid 6 parts

[0081] 3 parts concentrated sulfuric acid

[0082] Hydroquinone 0.55 parts

[0083] Acrylic 40 parts

[0084] Vinyl monomer 105 parts

[0085] Sodium sulfite 300 parts

[0086] Acetaldehyde solution 400 parts

[0087] oxidizing agent 40 parts

[0088] 15 parts of reducing agent.

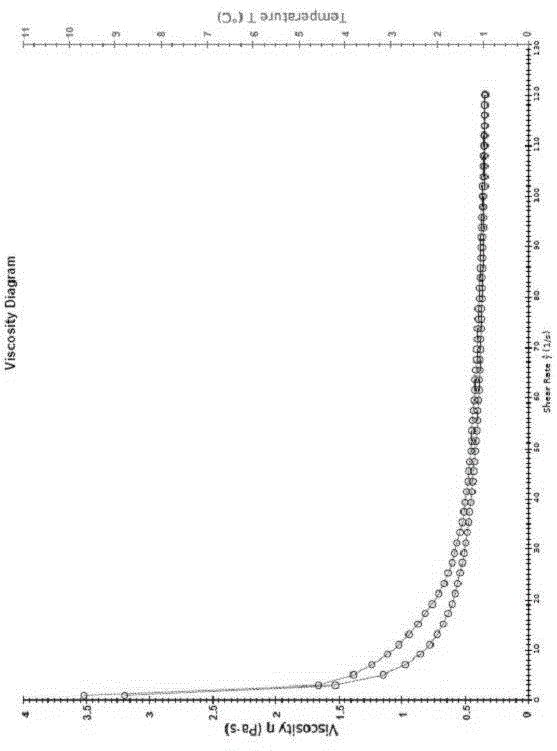

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com