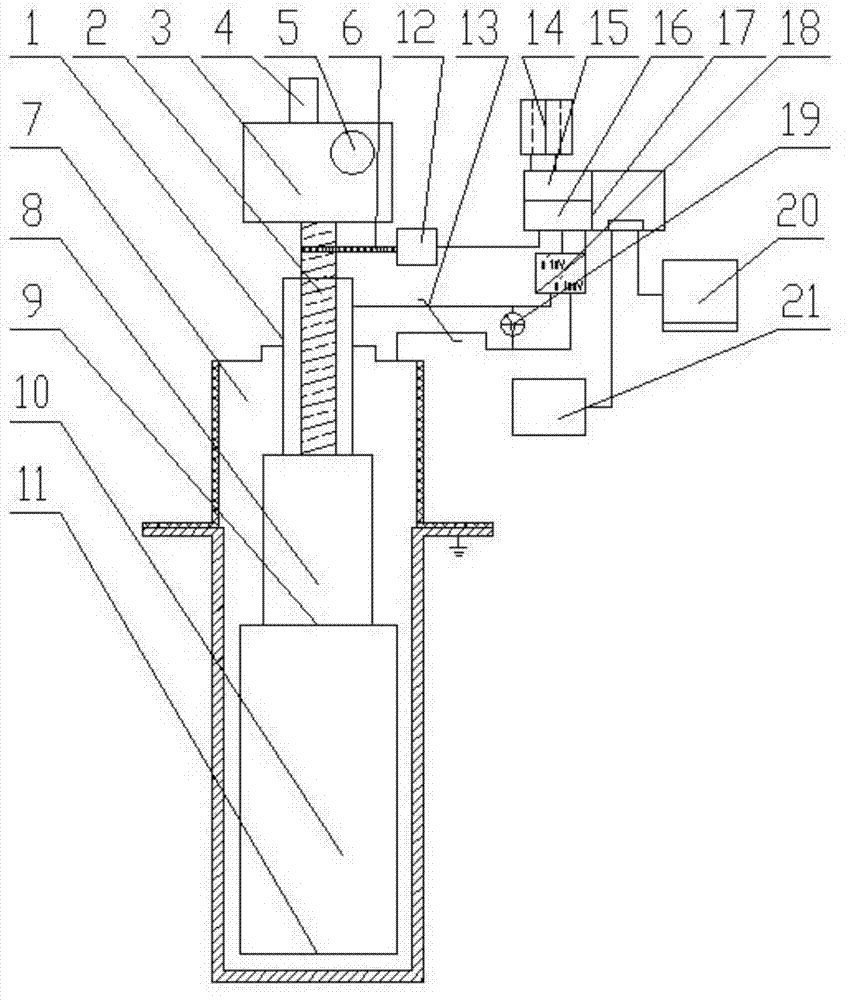

Automatic arcing device for vacuum consumable electric-arc furnace and control method

A vacuum consumable arc and consumable electrode technology, which is applied to electric heating devices, electrical components, heating through discharge, etc., can solve the problems of long time for stable melting, low success rate of one-time arc starting and low accuracy of arc distance control. , to achieve the effects of high success rate, improved yield rate, and reduced arcing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

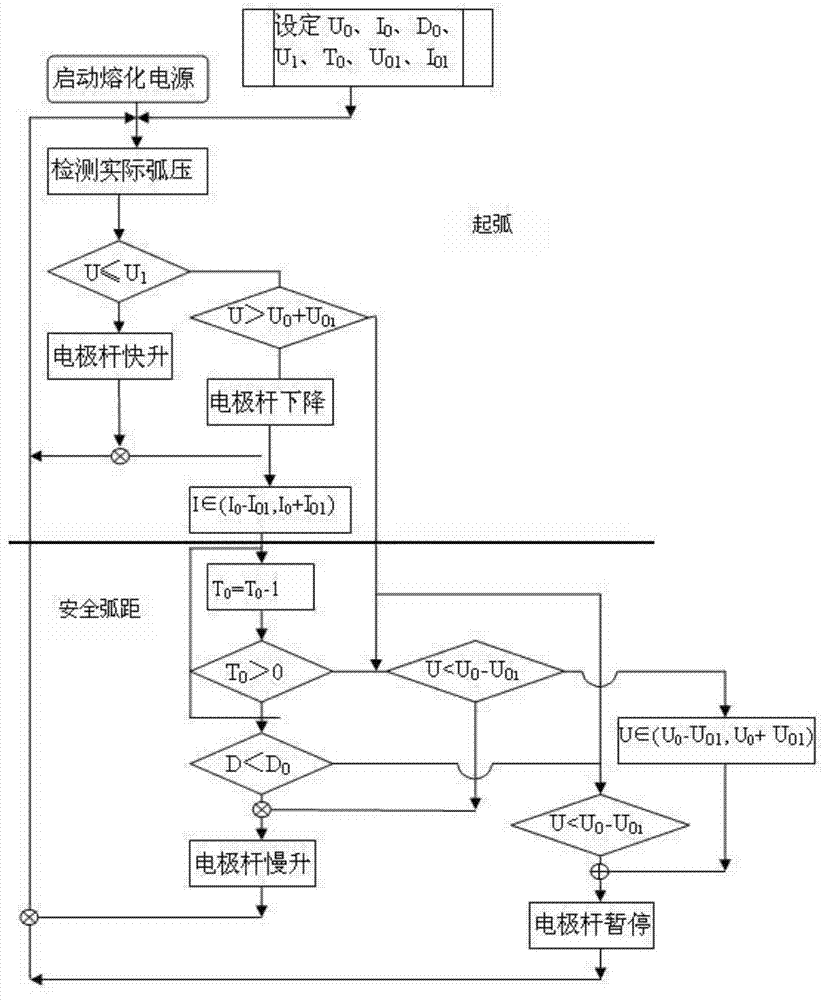

Method used

Image

Examples

Embodiment 1

[0043] In the case of adopting the device of the present invention, the titanium material is arc-started, and the arc-starting parameters are set on the industrial computer: arc-starting voltage U 0 =20V~26V, arc voltage variation U 01 =2V~3V, short circuit voltage U 1 =10V~13V, starting current I 0 =2A~4kA and current variation I 01 =0.5kA~1.0kA, starting time T 0 =2min~15min, arc distance D 0 =10mm~30mm. Then control according to the above steps.

Embodiment 2

[0045] In the case of adopting the device of the present invention, the titanium material is arc-started, and the arc-starting parameters are set on the industrial computer: arc-starting voltage U 0 =24V~30V, arc voltage variation U 01 =2V~4V, short circuit voltage U 1 =12V~16V, starting current I 0 =3A~7kA and current variation I 01 =0.5kA~1.2kA, starting time T 0 =10min~20min, arc distance D 0 =10mm~40mm. Then control according to the above steps.

Embodiment 3

[0047] In the case of adopting the device of the present invention, the titanium material is arc-started, and the arc-starting parameters are set on the industrial computer: arc-starting voltage U 0 =28V~36V, arc voltage variation U 01 =2V~5V, short circuit voltage U 1 =14V~18V, starting current I 0 =6A~10kA and current variation I 01 =1.0kA~1.5kA, starting time T 0 =18min~30min, arc distance D 0 =30mm~60mm. Then control according to the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com