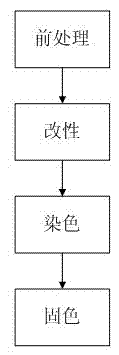

Fluorescent staining method for cotton fiber

A fluorescent dyeing and cotton fiber technology, which is applied in dyeing, textiles and papermaking, can solve the problems of uneven color, hard hand feeling and poor fastness of the cloth surface, and achieve the effect of improving the uniformity of the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Pre-treatment: first add water to the sample cup, then add degreaser and caustic soda in sequence, then put the cloth sample, put the sample cup into the proofer and heat up to 70°C, add H 2 o 2 4g / l, then raise the temperature to 98°C and keep it warm for 45 minutes. After the keep warm, take it out of the tank and wash it once, and the pretreatment is completed.

[0024] Modification: Add water to the sample cup, then add 4% modifier and put it into the cloth sample, put the sample cup into the proofer and run it for 5 minutes, then raise the temperature to 70°C at a rate of 1.5°C per minute and keep it for 30 minutes. The cylinder is washed once with water, and the modification is completed. The modifier is the fiber modifier Prefix K produced by Tuona Chemicals. The function of the modifier is mainly to change the original negative charge on the surface of the cotton fiber into a positive charge so that it can be combined with the negatively charged fluorescent pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com