Construction method for abutting high-altitude long-span roof pipe trusses by adjustable temporary support

A construction method and temporary support technology, applied in construction, building structure, construction material processing, etc., can solve problems such as undiscovered improved technical solutions, reduce risk factors and hidden safety hazards, improve utilization rate, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

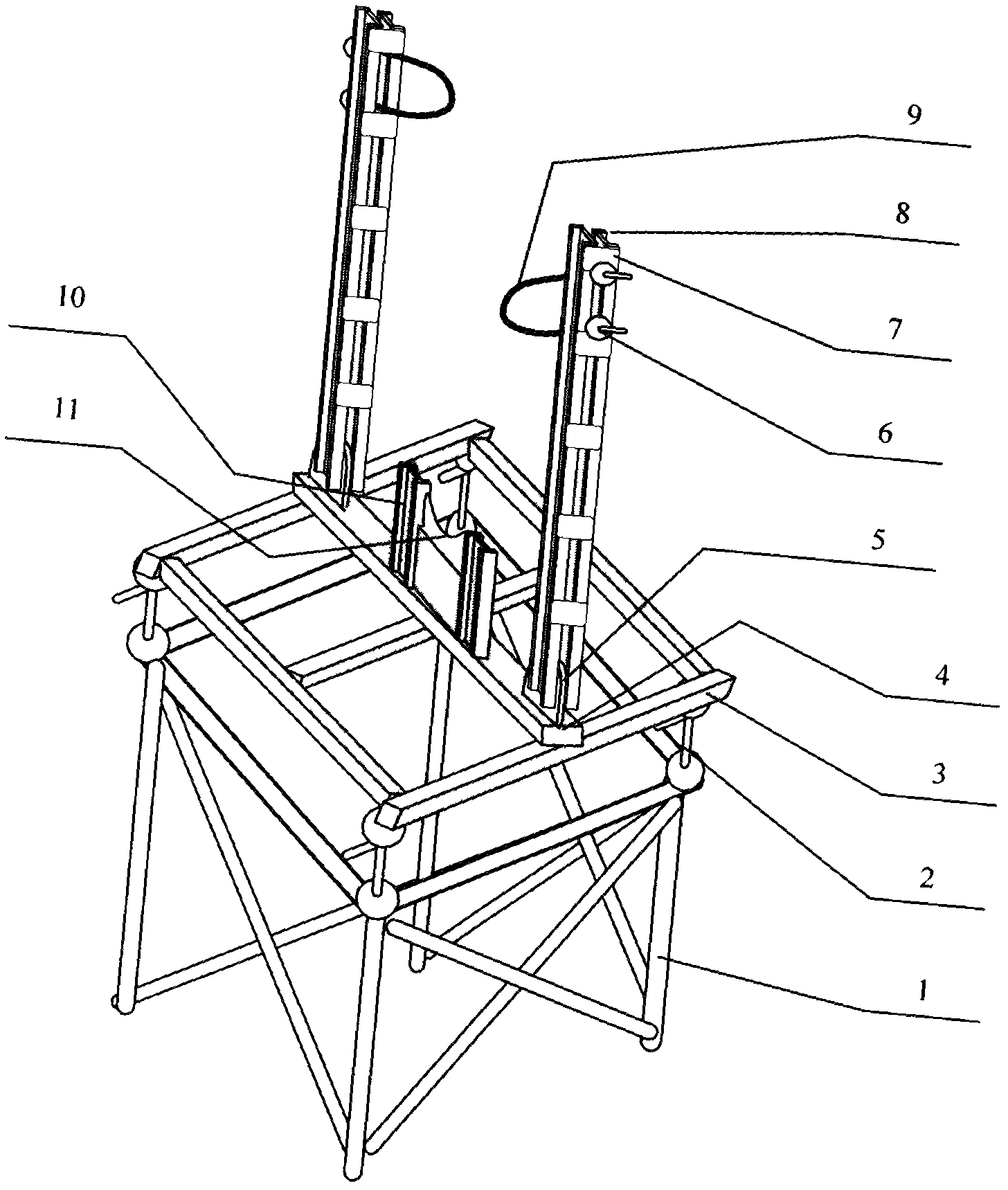

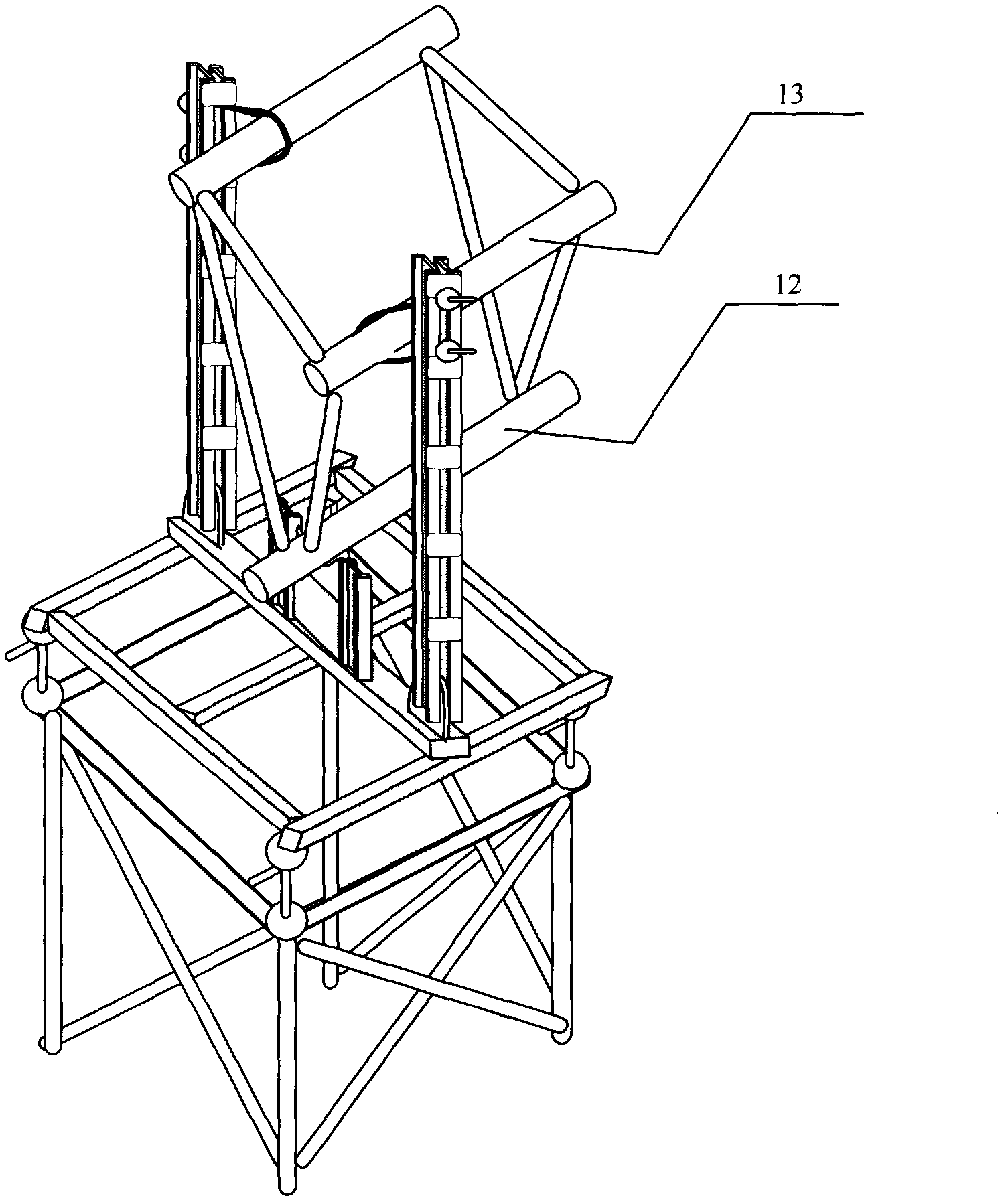

[0026] The main device for implementing the present invention includes standard section support frame 1, adjustable support 2, conversion platform 3, crossbeam 4, hinge support 5, nut 6, embossed plate 7, adjustable support leg 8, U-shaped fixing bolt 9. Support 10, arc brace 11, lower chord 12 and upper chord 13.

[0027] The conversion platform 3, the beam 4, the hinge support 5 and the arc brace 11 are made of section steel.

[0028] The construction method includes the following steps:

[0029] ①. Determine the position of the temporary support point, and set up the temporary standard section support frame 1 under the temporary support point;

[0030] ②. The upper flange of the temporary standard section support frame 1 is connected to the adjustable support 2;

[0031] ③. The upper part of the adjustable support 2 is flange-connected with the conversion platform 3;

[0032] ④. Weld the beam 4 on the conversion platform 3;

[0033] ⑤. The upper middle part of the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com