Engine control device

A control device and engine technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve problems such as torque shock, and achieve the effect of suppressing sudden change, improving convergence, and preventing long-term

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An engine control device will be described with reference to the drawings. In addition, the embodiment shown below is only an illustration, and it does not intend to exclude the application of various deformation|transformation and techniques which are not expressly shown in the following embodiment. The structures of this embodiment can be modified in various ways without departing from their gist, and can be selected or combined as needed.

[0036] [1. device structure]

[0037] [1-1. engine]

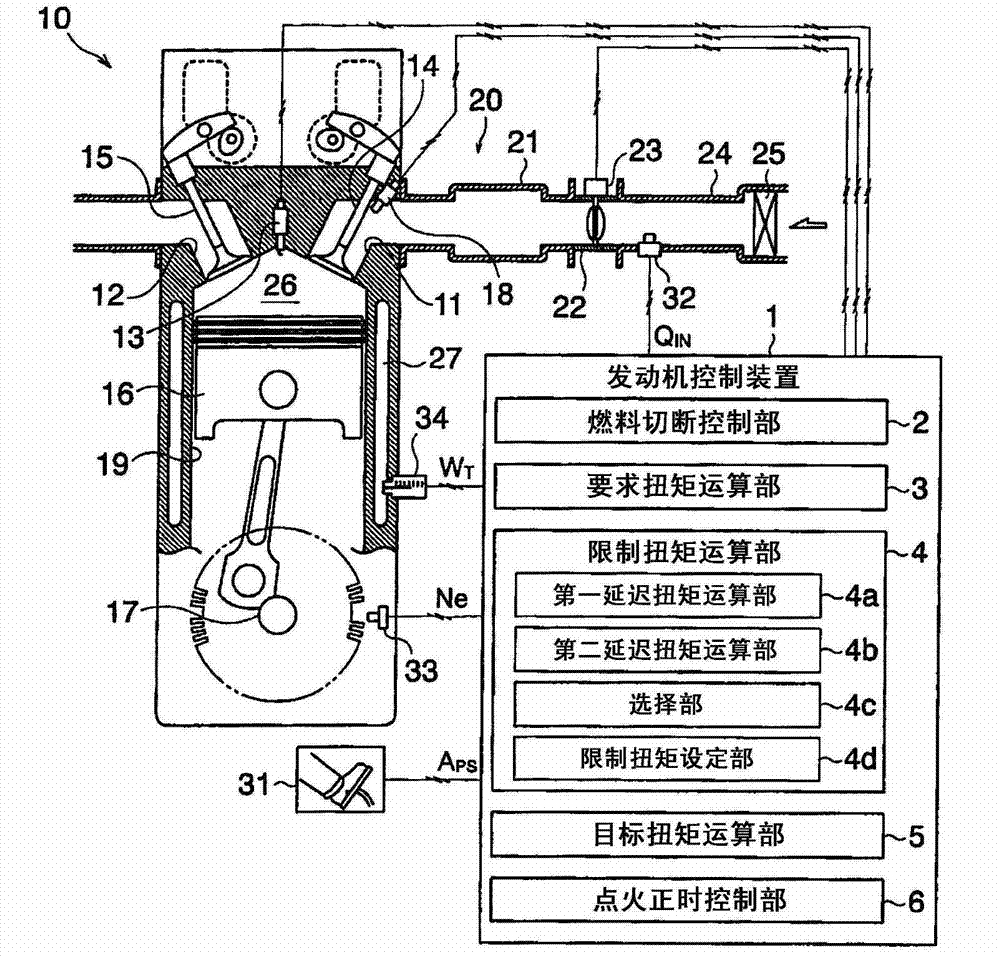

[0038] The engine control device of this embodiment is suitable for figure 1 An on-board gasoline engine 10 is shown. Here, one of the plurality of cylinders provided in the multi-cylinder engine 10 is shown. The piston 16 is attached so as to freely reciprocate and slide along the inner peripheral surface of a hollow cylindrical cylinder 19 . The space enclosed by the upper surface of the piston 16 and the inner peripheral surface and top surface of the cylinder 19 func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com