Flange-free plastic coated pipeline

A technology without flanges and pipes, applied in the field of pipes, can solve the problems of difficult construction, reduce the overall strength of the pipes, reduce the effective wall thickness of the welds, etc., and achieve the effects of convenient and fast construction, elimination of anti-corrosion blind spots, and stable and reliable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

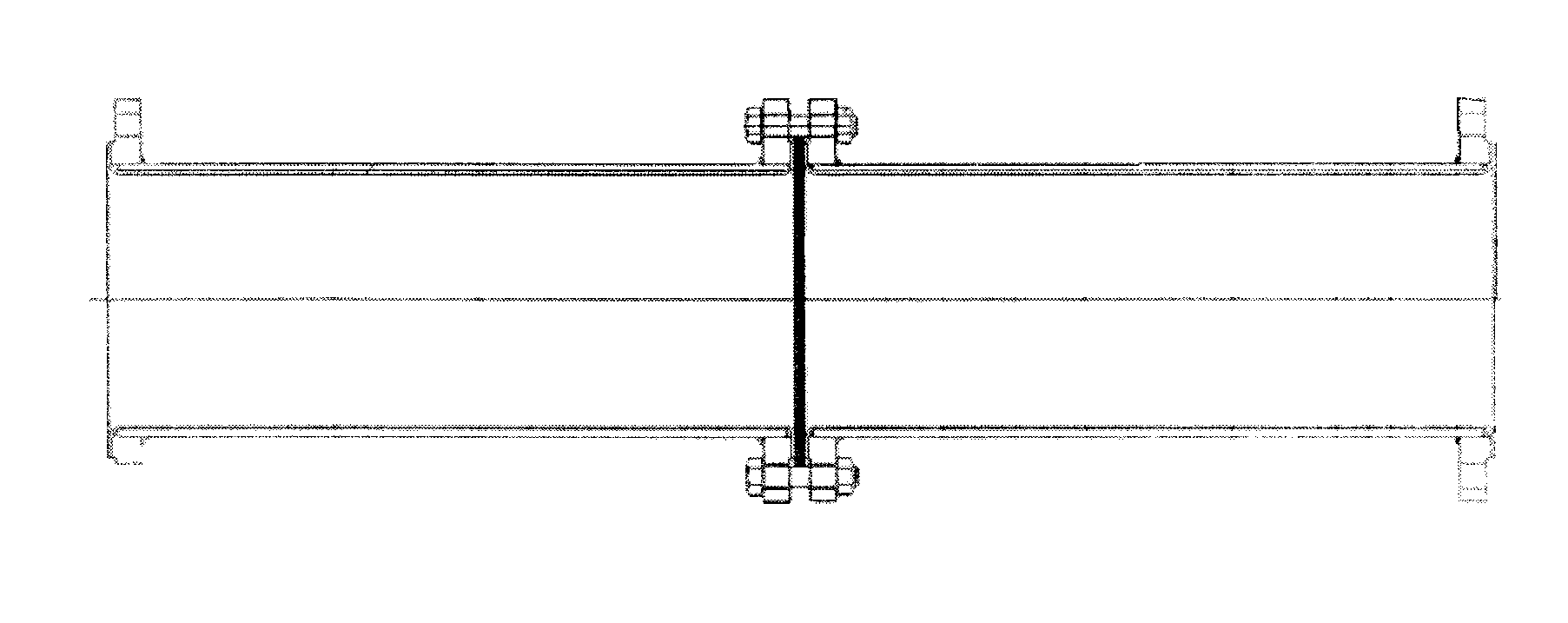

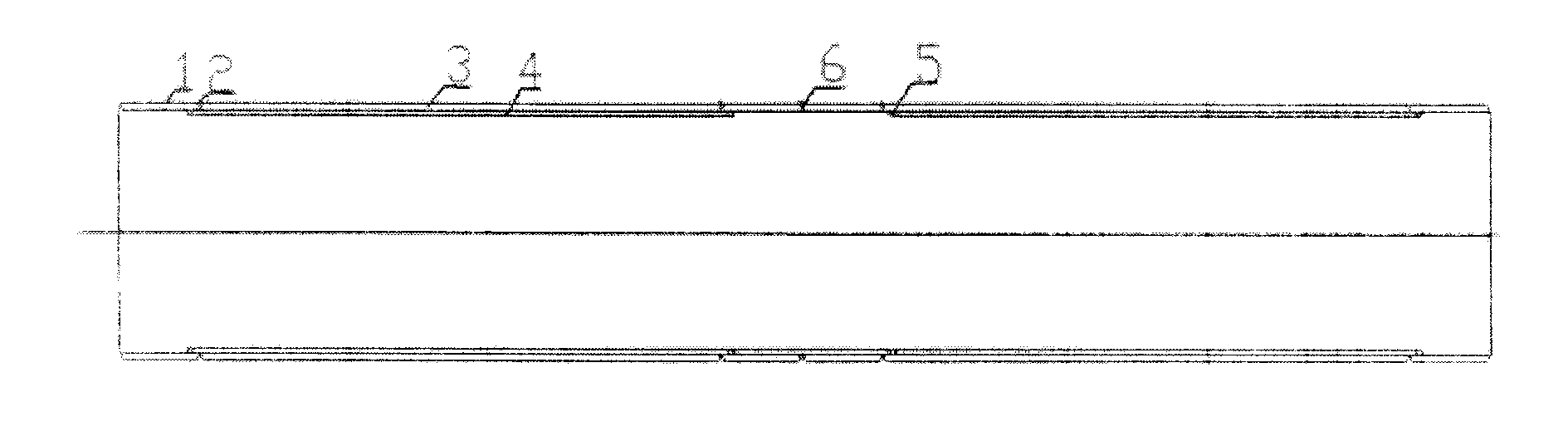

[0013] The structure and working process of the present invention will be further described with respect to an embodiment of the present invention with reference to the accompanying drawings.

[0014] Such as figure 1 As shown, the flangeless plastic-coated pipeline of the present invention includes: a carbon steel pipe main body, a stainless steel joint, a butt weld, a plastic-lined layer, a plastic-lined positioning ring, and a butt weld on site, and the stainless steel joint is butt-welded to the carbon The two ends of the steel pipe body are used to connect other pipes; the inner wall of the carbon steel pipe body is attached with the plastic-lined layer, and the plastic-lined positioning rings are respectively provided at both ends of the plastic-lined layer.

[0015] During construction, the stainless steel joint 1 is made of stainless steel with the same welding degree as the carbon steel pipe; the butt weld 2 has been processed before the factory products leave the fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com