Rare earth aluminum-base alloy for steelmaking deoxidization and preparation method thereof

A technology of rare earth aluminum base alloy and rare earth aluminum, which is applied in the field of rare earth aluminum base alloy for steelmaking deoxidation and its preparation, can solve the problems of adverse effects on the performance of molten steel, improve the distribution of inclusions, simplify the production process, and reduce the oxygen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

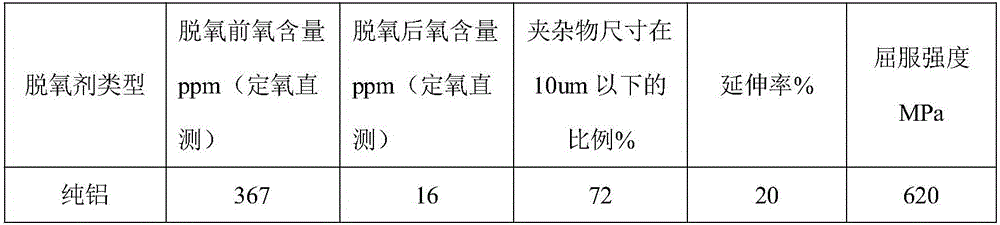

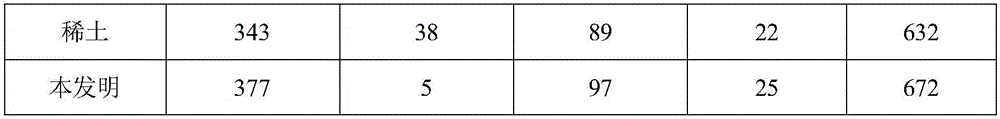

Embodiment 1

[0028] A deoxidizer for steelmaking, the composition of which is 98% aluminum and 2% rare earth by weight.

Embodiment 2

[0030] A deoxidizer for steelmaking, the composition of which is 95% aluminum and 5% rare earth by weight.

Embodiment 3

[0032] A deoxidizer for steelmaking, the composition of which is 90% aluminum and 10% rare earth by weight.

[0033] In the preferred embodiment 1 of the present invention, the chemical composition ratio (weight %) of the prepared rare earth aluminum-based alloy for steelmaking is: 98% aluminum, 2% mixed rare earth. Its preparation steps are as follows:

[0034] 1. First, mix metal aluminum and rare earth according to the ratio of 98 to 2, and weigh 200g of mixed rare earth and 9800g of metal aluminum.

[0035] 2. Take out 4000g of the weighed aluminum metal and place it in a vacuum induction furnace, then vacuumize it to a vacuum degree of 30Pa to heat and melt the metal aluminum.

[0036] 3. Add the mixed rare earth to the molten aluminum in a vacuum environment, the temperature of the mixed rare earth is controlled at about 750°C, and the holding time is 20 minutes. Electromagnetic stirring homogenization treatment is carried out before pouring, electromagnetic stirring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com