Skin anastomat (stitching instrument) with arc-shaped fastening mechanism

A skin, arc-shaped technology, applied in the direction of surgical fixation nails, etc., can solve the problems of weak welding, inability to rework, and high rejection rate, and achieve the effects of stable and reliable product quality, confirmed product process, and reduced rejection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural principle and working principle of the present invention will be further described in detail below.

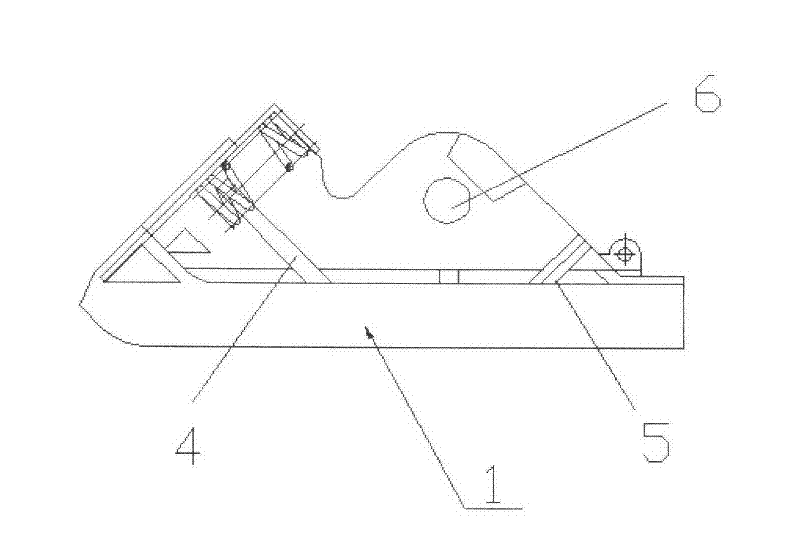

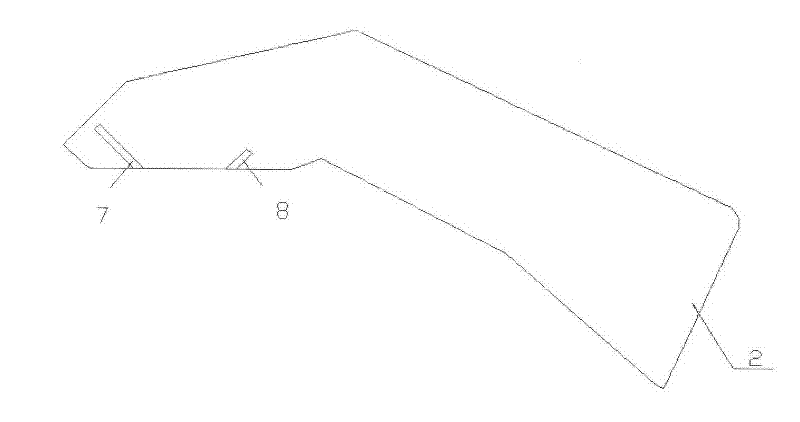

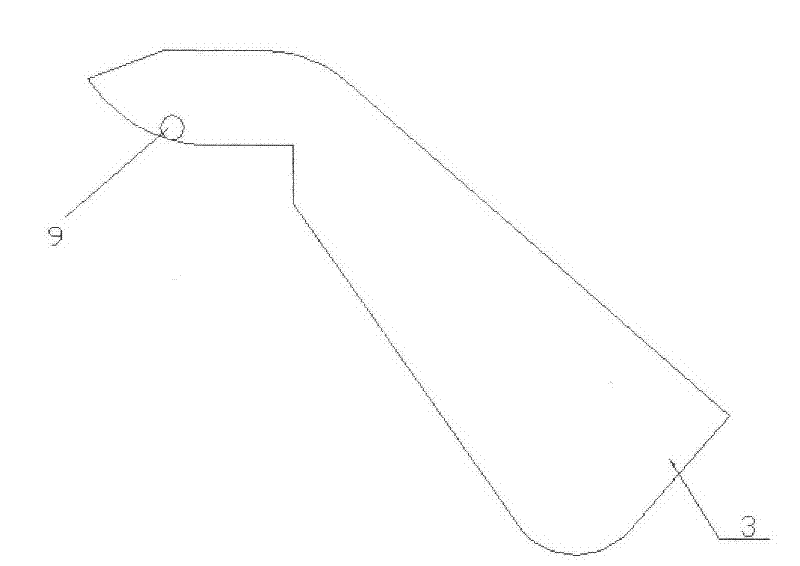

[0031] A skin anastomotic (suture) stapler with an arc-shaped interlocking mechanism is composed of a needle box assembly 1, an upper handle 2 and a lower handle 3, and the needle box assembly 1 includes a first outer rib 4 and a The second outer rib 5, the needle box assembly 1 is also provided with a first mounting hole 6, the lower handle 3 is provided with a second mounting hole 9, the first mounting hole 6 and the second mounting hole 9 are fixedly connected, The bottom end side of the upper handle 2 is provided with a first groove 7 and a second groove 8, the first groove 7 and the first outer rib 4, the second groove 8 and the second outer rib 5 Cooperate with each other to set up;

[0032] The first outer rib 4 is longer than the second outer rib 5;

[0033] Both the first outer rib 4 and the second outer rib 5 form an included angle of 45 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com