Position dimension control tool and method for outer hanging pieces of combustor shell

An external pendant and combustion chamber technology, applied in the field of ultra-high-strength steel pressure vessel manufacturing, can solve problems such as large economic losses, scrapped combustion chamber shells, and large shell surface risks, and achieves solutions to position size deviation and product quality. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

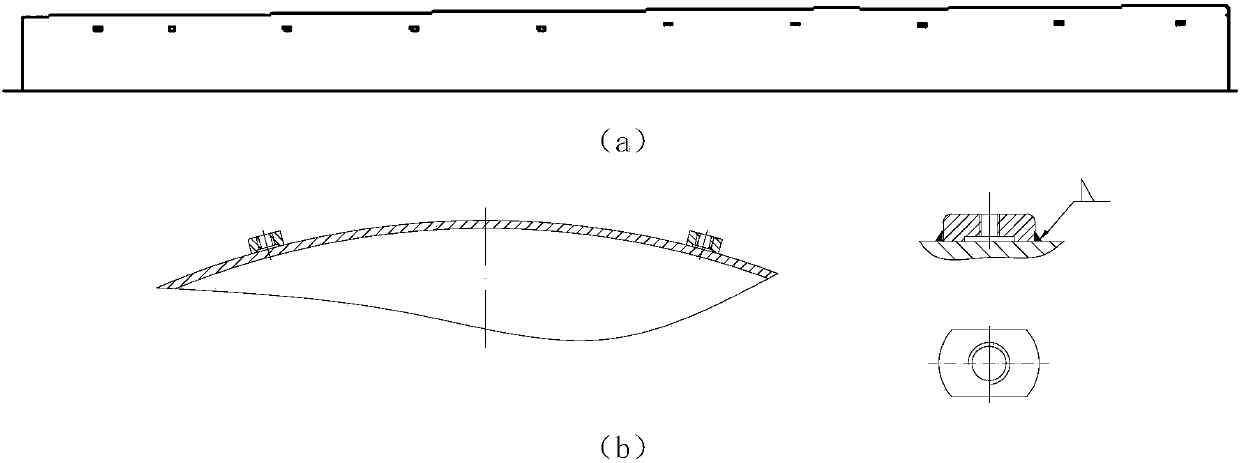

[0021] (1) Clamping mechanism for external parts and positioning fixture for assembly and welding

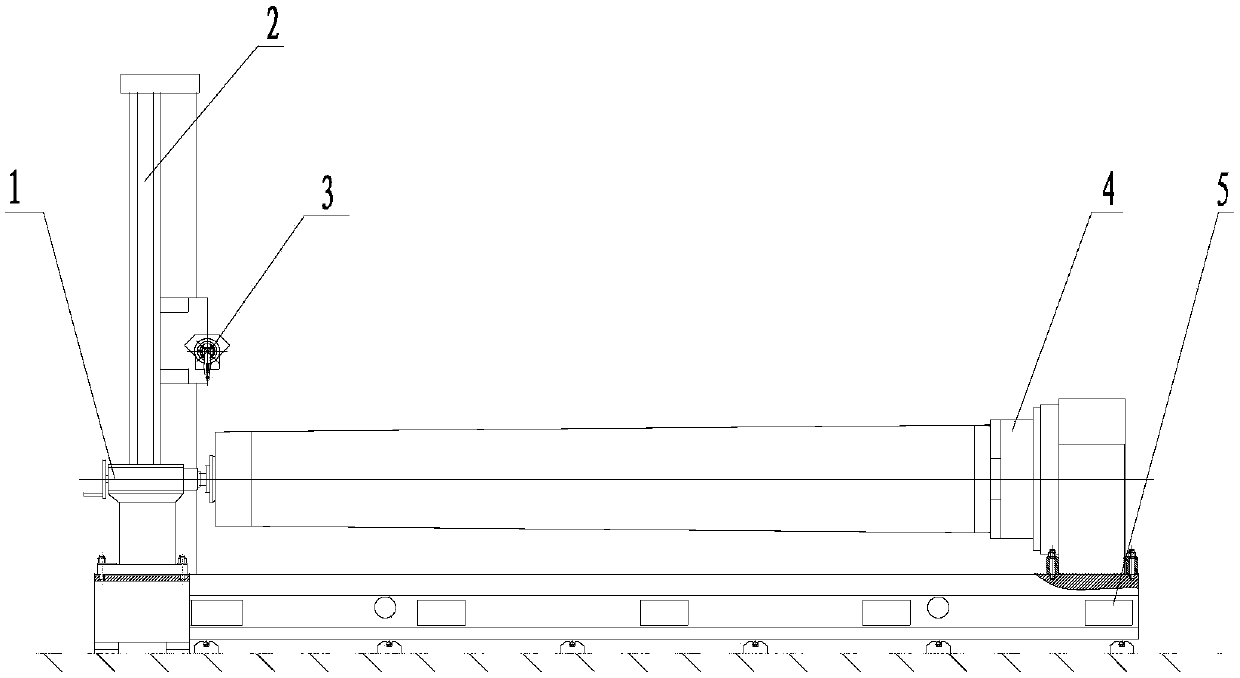

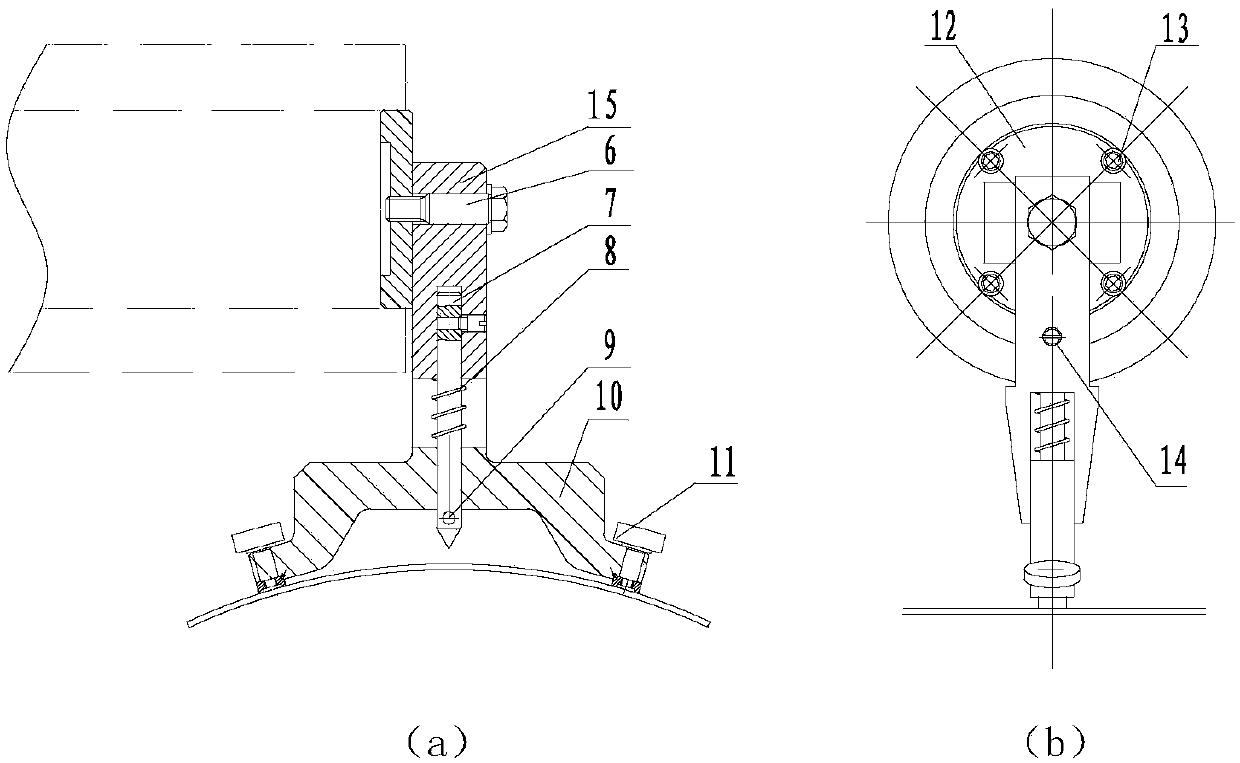

[0022] Use the clamping mechanism to clamp and align the combustion chamber shell. According to the characteristics of the structure and distribution of the external hanging parts of the combustion chamber shell, a welding positioning fixture for the external hanging parts is designed. It is used with the clamping mechanism to ensure the axial and circumferential directions of the external hanging parts. Position accuracy requirements, but also meet the requirements of positioning welding for external parts assembly.

[0023] The hanging parts positioning welding system mainly includes two parts: the combustion chamber shell clamping mechanism and the hanging parts welding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com