Air processing unit

An air handling unit and unit technology, applied in the field of air purification, can solve problems such as unfavorable production continuity in production workshops, short service life of chemical filters, and affecting continuous working time of fan filter units, so as to improve continuous working time and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

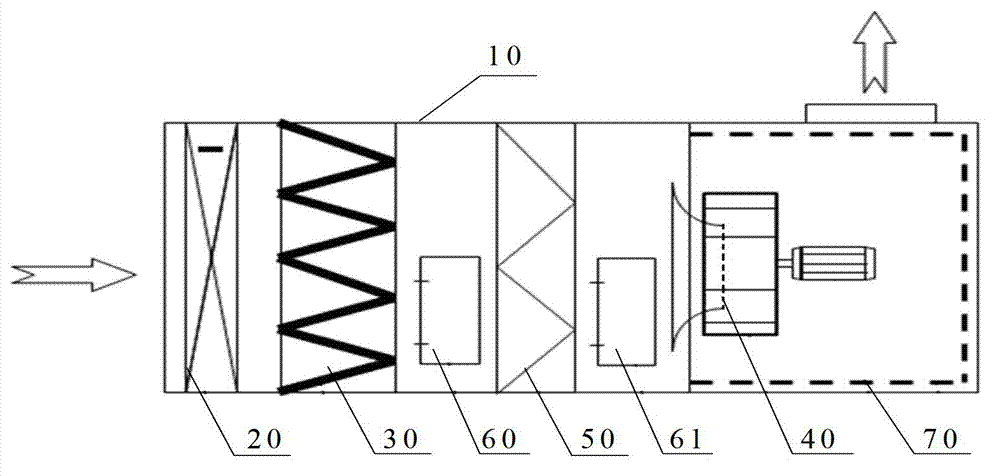

[0034] Example one, as figure 1 As shown, the air handling unit provided by Embodiment 1 of the present invention includes: a unit casing 10 having an air inlet and an air outlet, a fan 40 arranged in the unit casing 10, a dry surface cooler 20 and a chemical filter 30 ;in,

[0035] The dry surface cooler 20, the chemical filter 30 and the fan 40 are arranged in sequence along the air flow direction from the air inlet to the air outlet.

[0036] In this embodiment, the dry surface cooler 20, the chemical filter 30 and the fan 40 are sequentially installed in the same unit casing 10, that is, the air handling unit has its own fan, so that the chemical filter 30 can use a thicker adsorbent layer, thereby prolonging the service life of the chemical filter, thereby increasing the continuous working time of the air handling unit, and at the same time controlling the temperature in the production workshop.

[0037] Preferably, the adsorbent layer of the above-mentioned chemical fi...

Embodiment 2

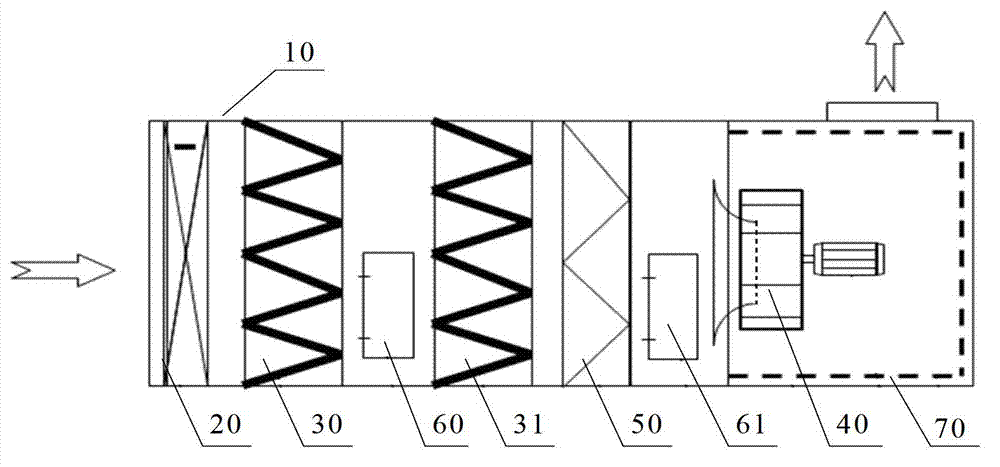

[0042] Example two, as figure 2 As shown, the air handling unit provided by Embodiment 2 of the present invention includes: a unit casing 10 having an air inlet and an air outlet, a fan 40 arranged in the unit casing 10, a dry surface cooler 20, and two chemical filters 30, 31; among them,

[0043] The dry surface cooler 20, the chemical filter 30, the chemical filter 31 and the blower 40 are arranged in sequence along the flow direction of the airflow from the air inlet to the air outlet.

[0044] In this embodiment, the dry surface cooler 20, the chemical filter 30, the chemical filter 31 and the fan 40 are installed in the same unit casing 10, that is, the air handling unit has its own fan, so that the air handling unit can use two A chemical filter, and each chemical filter can use a thicker adsorbent layer, which increases the saturation time of the adsorbent layer, thereby prolonging the service life of the chemical filter, thereby increasing the continuous working tim...

Embodiment 3

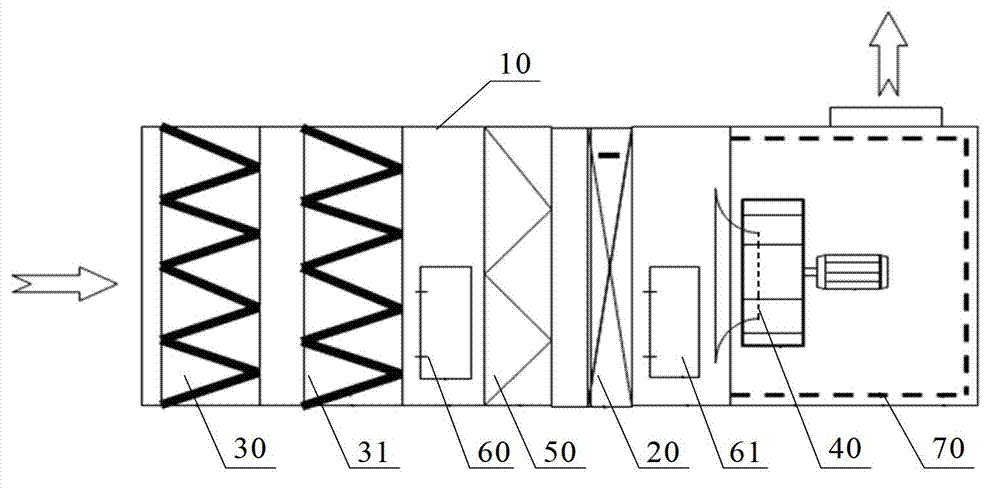

[0048] Example three, as Figure 5 As shown, the air handling unit provided by Embodiment 3 of the present invention includes: a unit casing 10 having an air inlet and an air outlet, a fan 40 arranged in the unit casing 10, a dry surface cooler 20, and three chemical filters 30, 31, and 32; of which,

[0049] The dry surface cooler 20 , the chemical filter 30 , the chemical filter 31 , the fan 40 and the chemical filter 32 are sequentially arranged in the unit housing 10 along the air flow direction from the air inlet to the air outlet.

[0050] In this embodiment, the dry surface cooler 20, the chemical filter 30, the chemical filter 31, the fan 40 and the chemical filter 32 are sequentially arranged in the same unit casing 10, that is, the air handling unit has its own fan, so that the air treatment unit The unit can use three chemical filters, and each chemical filter can use a thicker adsorbent layer, which increases the saturation time of the adsorbent layer, thereby pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com