Wing test element for ice wind tunnel of anti-icing system for aircraft wing

An anti-icing system and test piece technology, applied in the field of airfoil test pieces, can solve the problems that the airfoil test piece deviates from the real situation, and it is difficult to provide guarantee for the performance verification of the wing anti-icing system, so as to achieve simple design and avoid negative effects. , the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

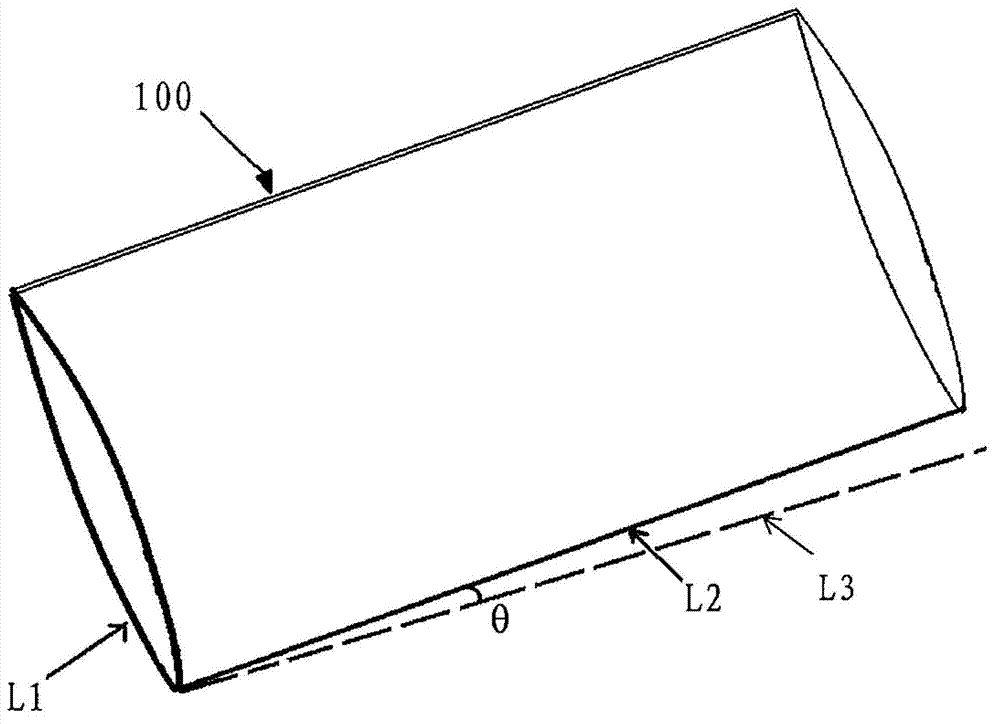

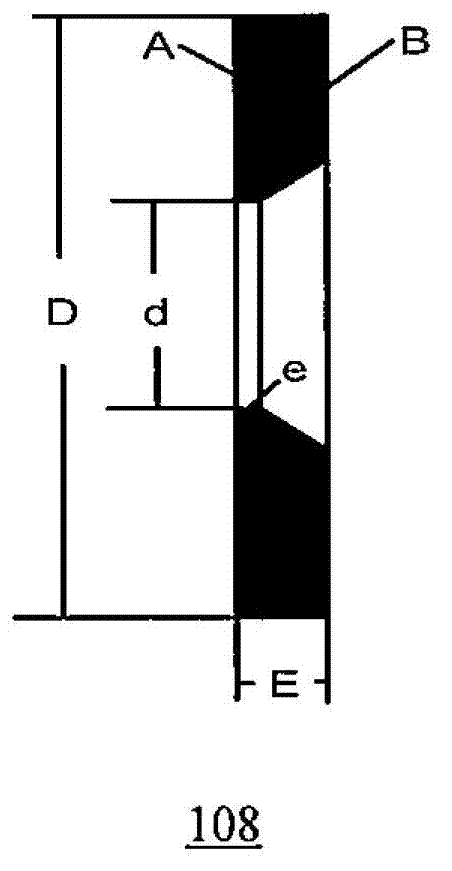

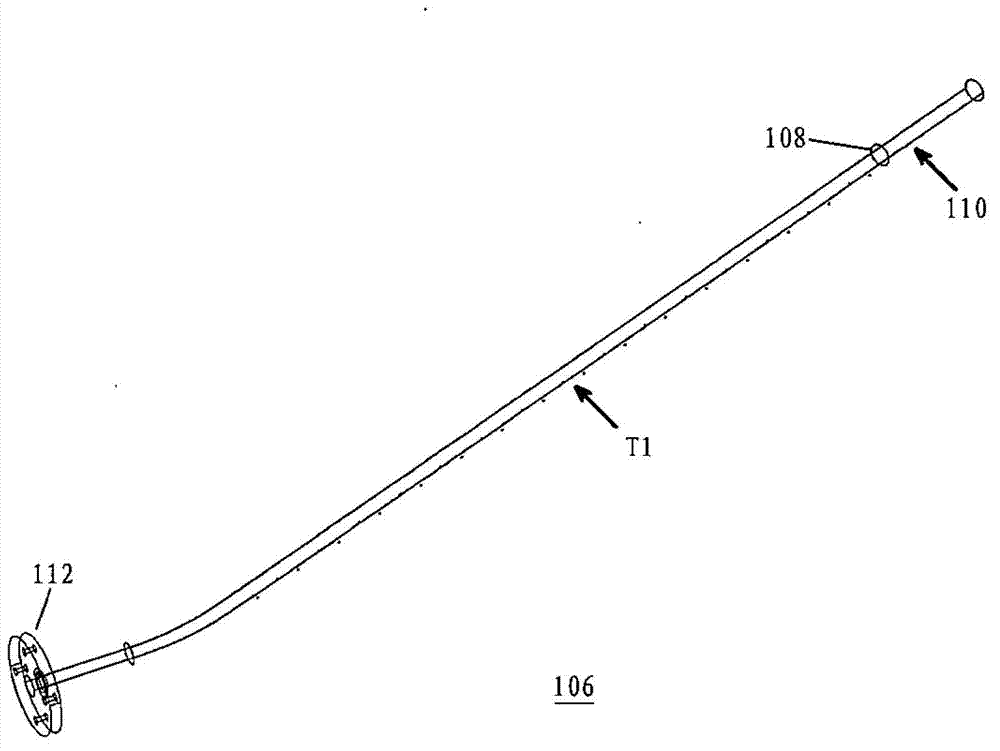

[0032] Hereinafter, the wings and piccolos refer to the wings of the real aircraft to be verified and the piccolos in the wing anti-icing system. The airfoil test piece refers to the test piece used for the ice wind tunnel test. It is different from the complex wing airfoil of the real aircraft. It is a simplified design based on the outer flow field and the characteristics of the flute tube of the real aircraft wing. The test piccolo is a component of an airfoil test piece that is used to simulate the piccolo in a real aircraft wing.

[0033] 1) Determine the critical section according to the analysis

[0034] First, it is necessary to determine the water droplet impact characteristics of the wing along the span direction through computational analysis. Among them, the analysis of the impact characteristics of water droplets refers to the analysis of the local water collection coefficient based on the calculation of the external flow field of the wing, where the local wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com