Double frame connecting structure of eyeglass frame

A spectacle frame and frame technology, which is applied in the field of double-frame connection structure, can solve the problems of high difficulty, lens drop, and time-consuming lens installation, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

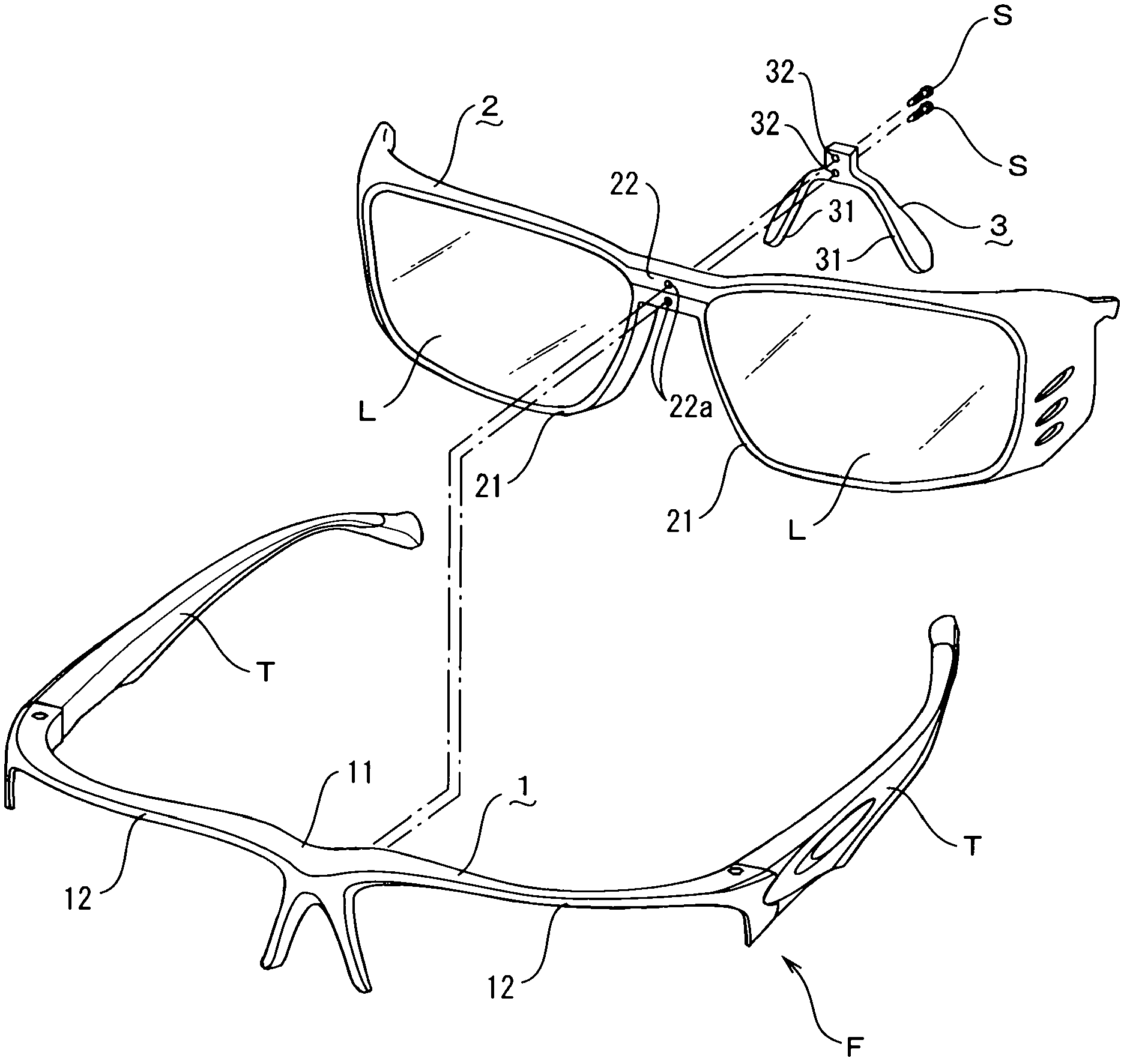

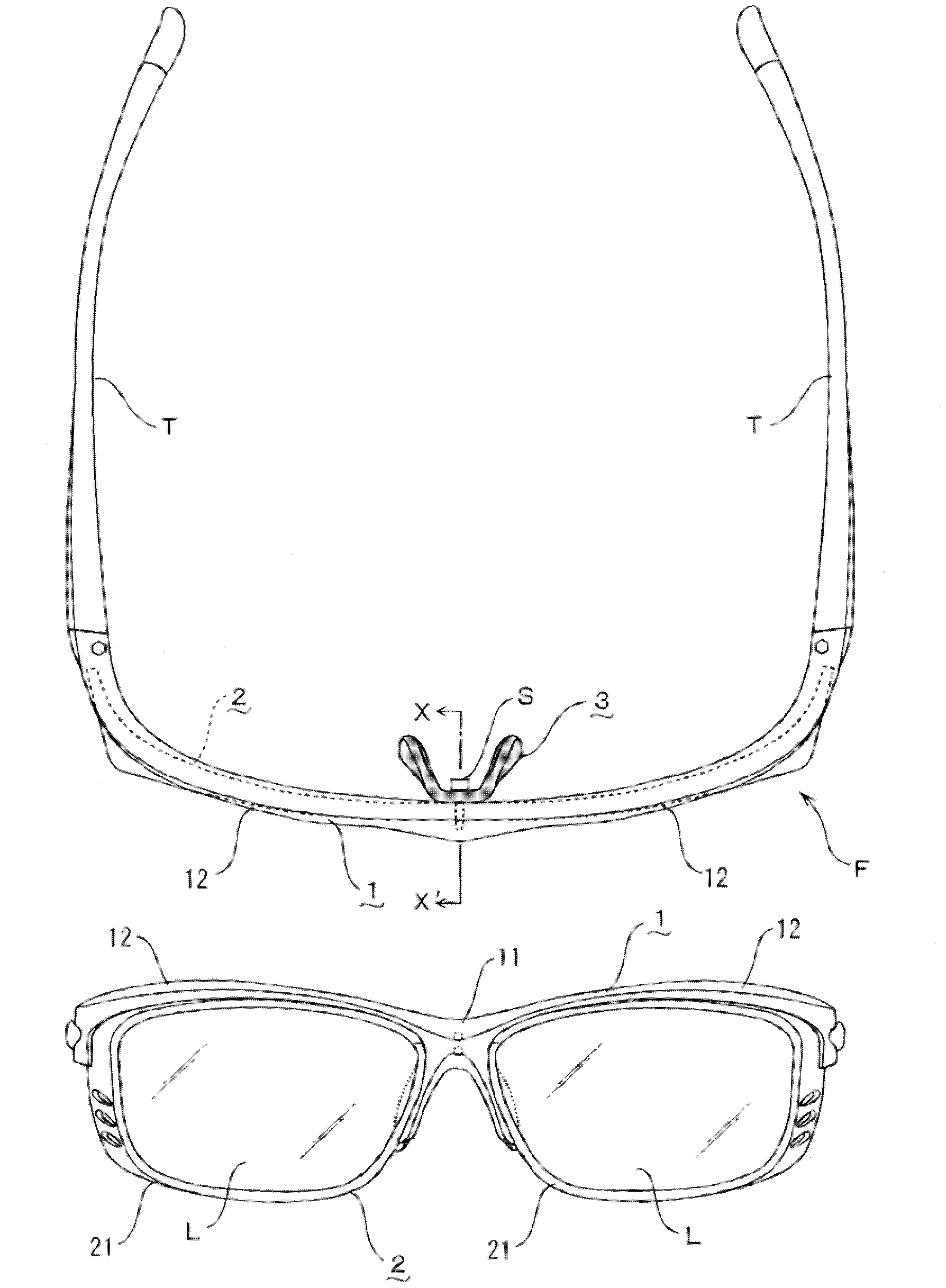

[0043] based on Figure 1 to Figure 5 , to illustrate Embodiment 1 of the present invention. In addition, in this figure, the part indicated by the symbol 1 is a holding frame, and the part indicated by the symbol 2 is an inner frame. In addition, the part indicated by the symbol 3 is a nose pad.

[0044] First, in Example 1, the inner frame 2 having the left and right mirror rings 21, 21 and the saddle-shaped nose pad 3 integrally having the left and right stipples 31, 31 are attached to the temples T, The back side of the brow bar type holding frame 1 of T constitutes the front part of the spectacle frame F (see figure 1 , figure 2 ).

[0045] In addition, with respect to the above-mentioned holding frame 1 and inner frame 2, lenses L, L of the inner frame 2 are arranged on the lower side of the brows 12, 12 connected from the first nose bridge 11 of the holding frame 1 to the left and right ends, so that When looking through the lenses L, L of the inner frame 2, the f...

Embodiment 2

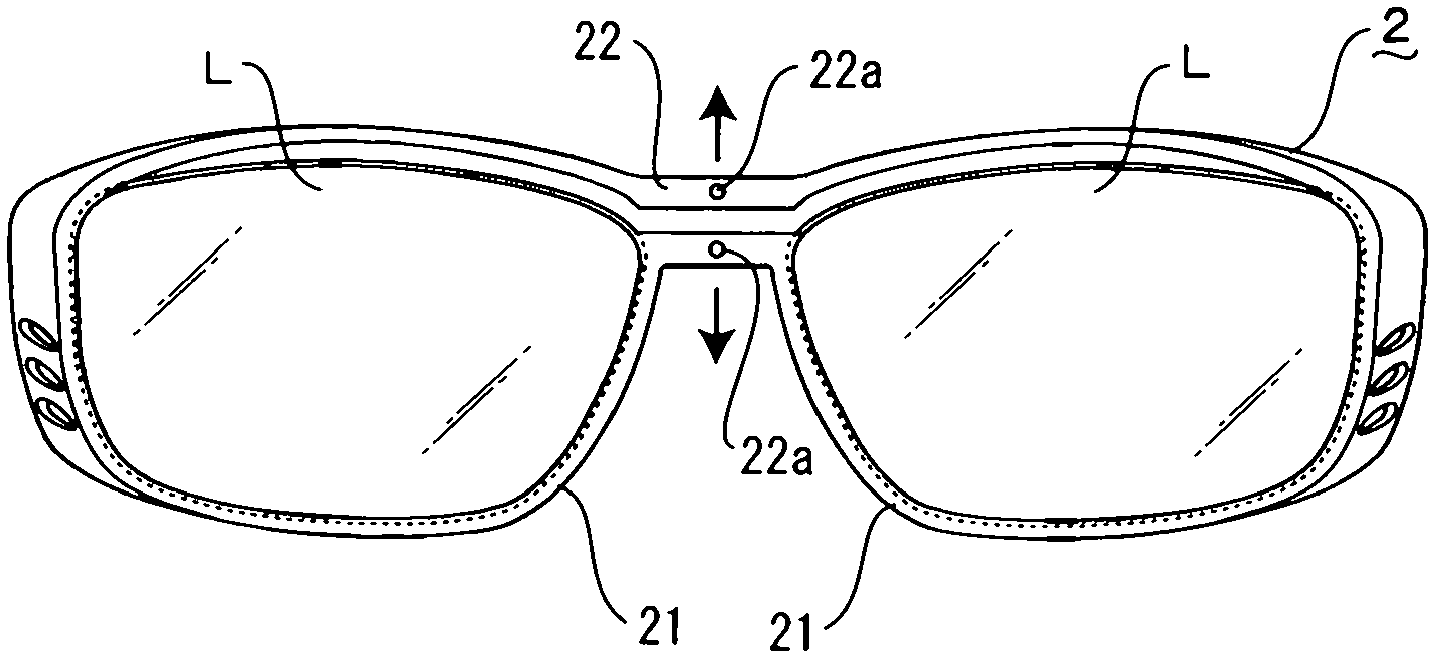

[0055] Next, based on Figure 6 , Embodiment 2 of the present invention will be described below. In this embodiment 2, as far as the installation configuration of the holding frame 1 and the inner frame 2 is concerned, as Figure 6 As shown in (a), on the back of the first nose bridge 11 of the holding frame 1, locking protrusions 11c, 11c are arranged up and down, and the second nose bridge 22 of the inner frame 2 and the nose pad 3 are provided with the locking protrusions. The insertion holes 22a, 32 into which 11c, 11c are inserted can be Figure 6 In the state shown in (b), the inner frame 2 and the nose pad 3 are attached to the back side of the holding frame 1 .

Embodiment 3

[0057] Next, based on Figure 7 and Figure 8 , Embodiment 3 of the present invention is described as follows. In the figure, the components indicated by the symbol 4 are preceded by a box. In this embodiment 3, by connecting temple T, T on both sides and a pair of lenses L, L can be installed on the left and right lens rims 14, 14 by the holding frame 1 and the front of the holding frame 1. The front frame 4 on the side constitutes the front of the spectacle frame F (see Figure 7 ).

[0058] In addition, the first nose bridge 11 of the above-mentioned holding frame 1 is the same as the inner frame of embodiment 1, and its upper and lower centers are cut in the lateral direction from the inner side of one mirror ring 14 to the inner side of the other mirror ring 14. The lenses L, L are mounted in a state where the bridge of the nose 11 is opened up and down. In addition, in this embodiment, a metal frame is used as the holding frame 1 .

[0059] Furthermore, in the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com