Planar magnetron sputtering cathode

A magnetron sputtering, planar technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of damage to coating equipment, uneven etching, and high coating costs, and achieve improved utilization, wider etching area, and magnetic field. The effect of uniform intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

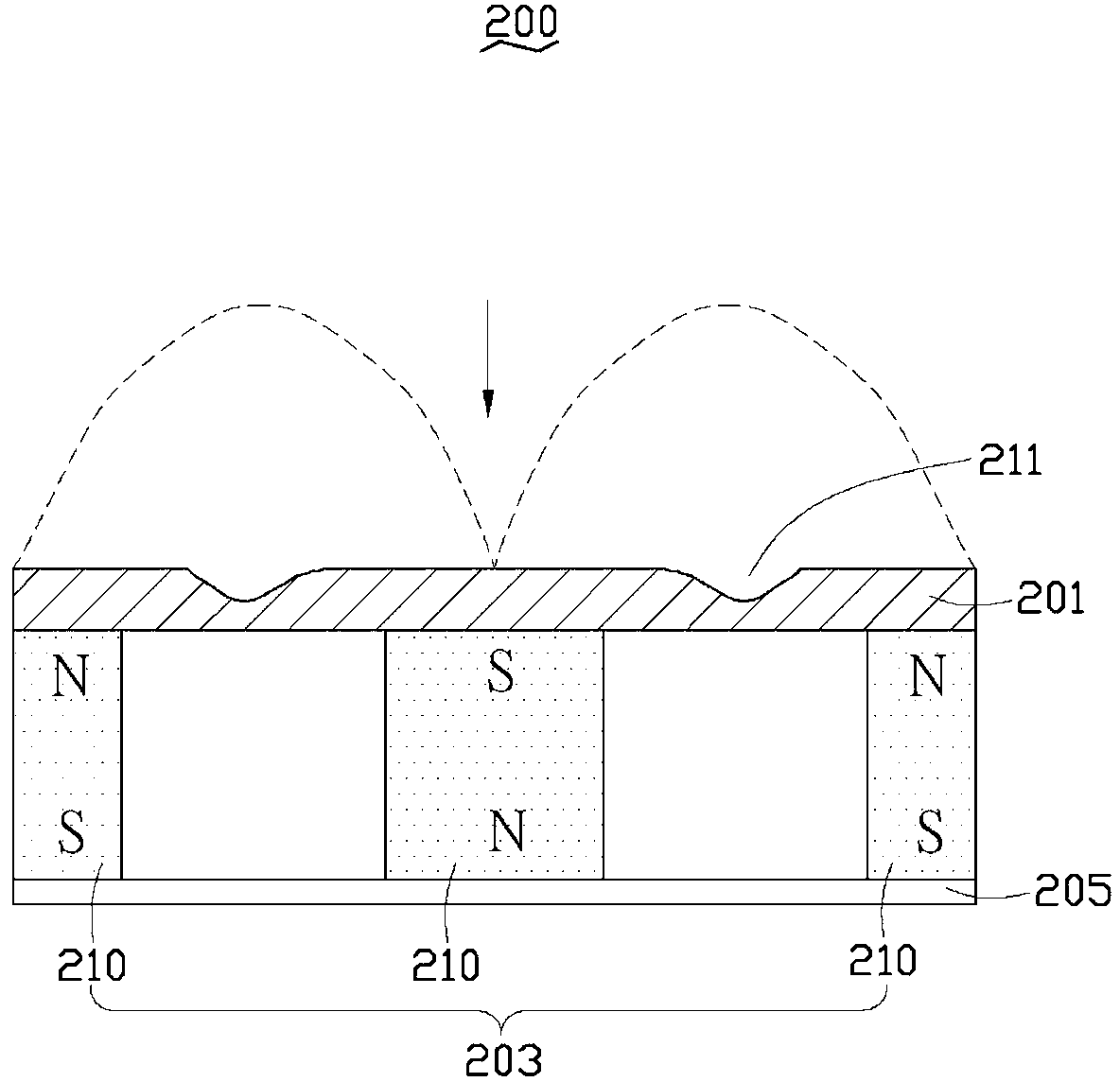

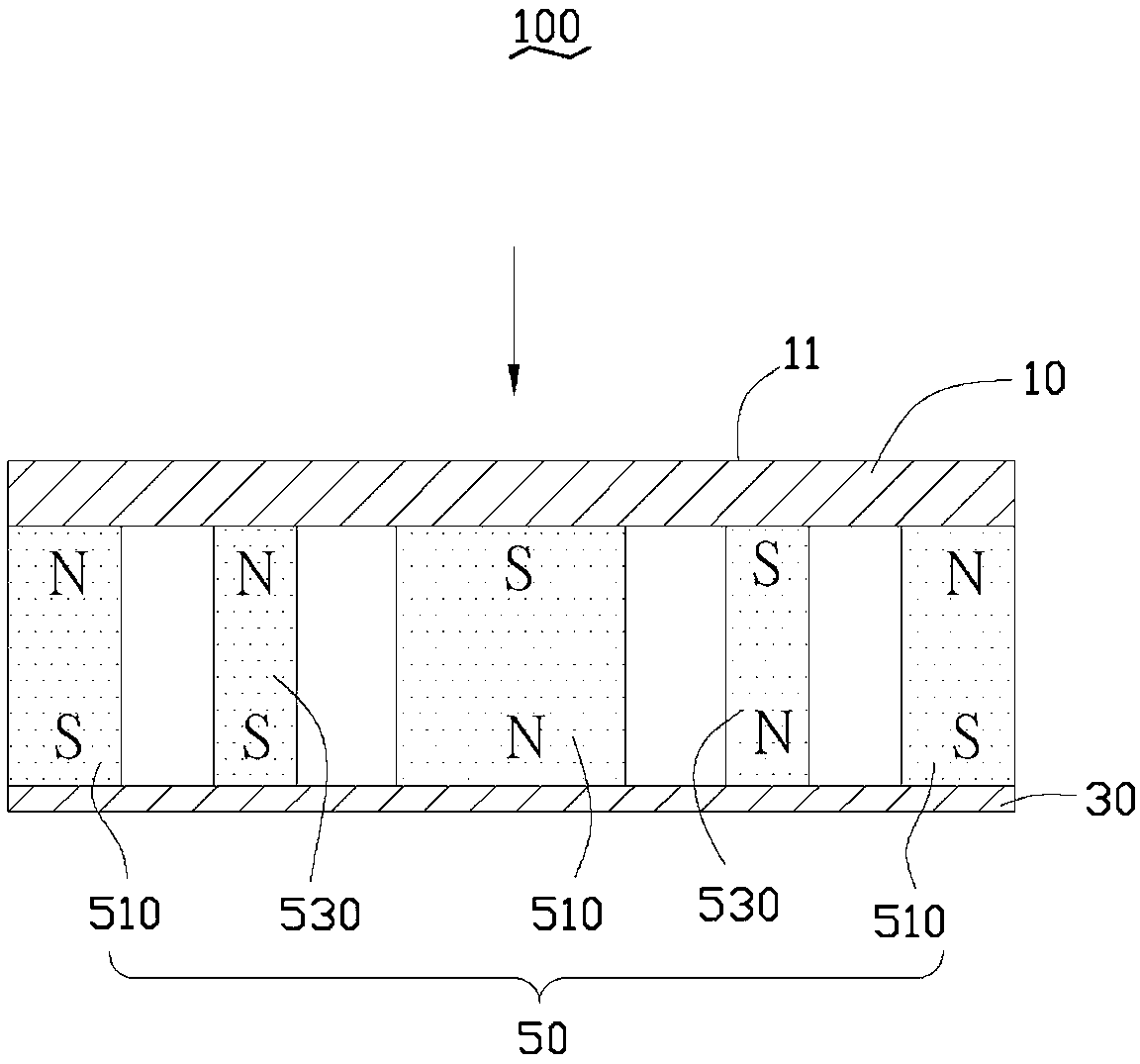

[0018] see image 3 , the planar magnetron sputtering cathode 100 of the present invention includes a target 10 , a magnet device 50 , and a magnetic shoe 30 . The target 10 is a planar target, which includes a sputtering surface 11 . The magnet device 50 is vertically installed on a side of the target 10 opposite to the sputtering surface 11 , and the magnetic shoe 30 is arranged on a side of the magnet device 50 away from the target 10 . The magnetic shoe 30 is used to shield the magnetic field of the side of the magnet device 50 adjacent to the magnetic shoe 30 .

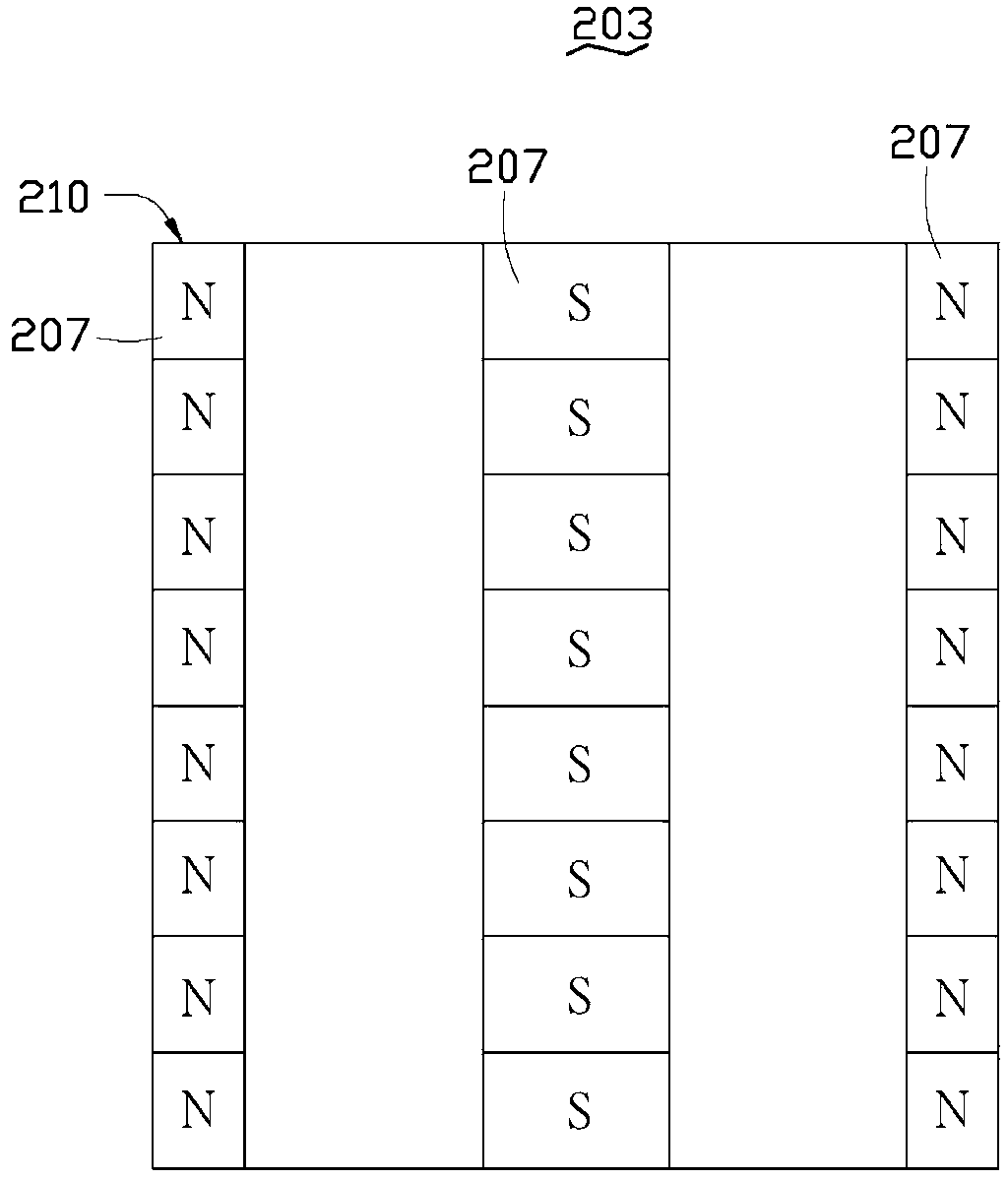

[0019] The magnet device 50 includes three first magnets 510 and two second magnet groups 530 . The three first magnets 510 are arranged at equal intervals on both sides and in the middle of the target 10 , and the polarity arrangement of each adjacent two first magnets 510 is opposite.

[0020] Please also refer to Figure 4 , Figure 4 shown as image 3 After removing the target 10, from image 3 The mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com