Cathode exhaust recirculating system for proton exchange membrane fuel cell

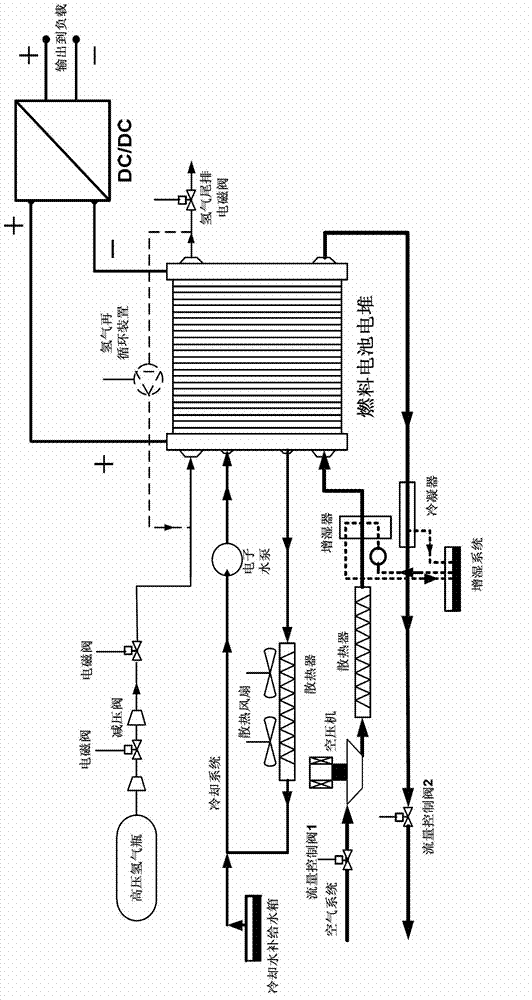

A technology for exhaust gas recirculation and recirculation system, which is applied to fuel cells, fuel cell additives, electrical components, etc., and can solve the problems of effective life attenuation, increase in volume and cost of mechanical and chemical filters, and accelerated stack attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

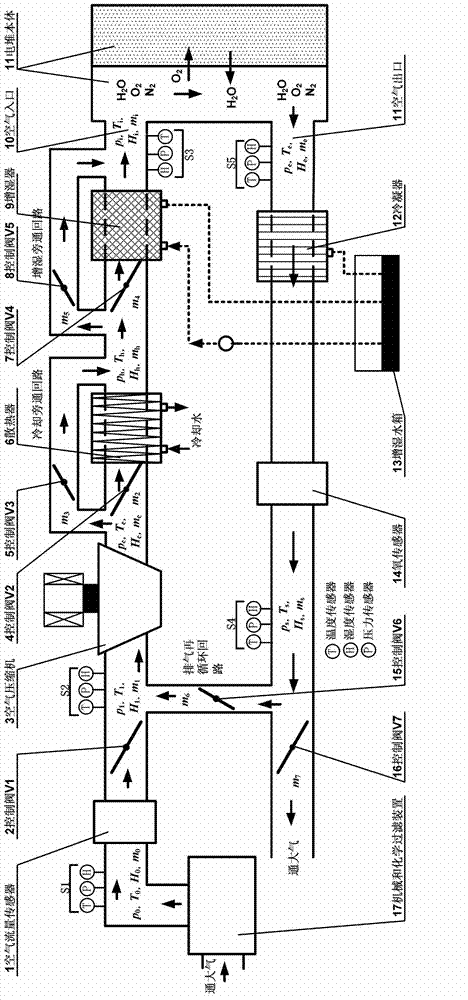

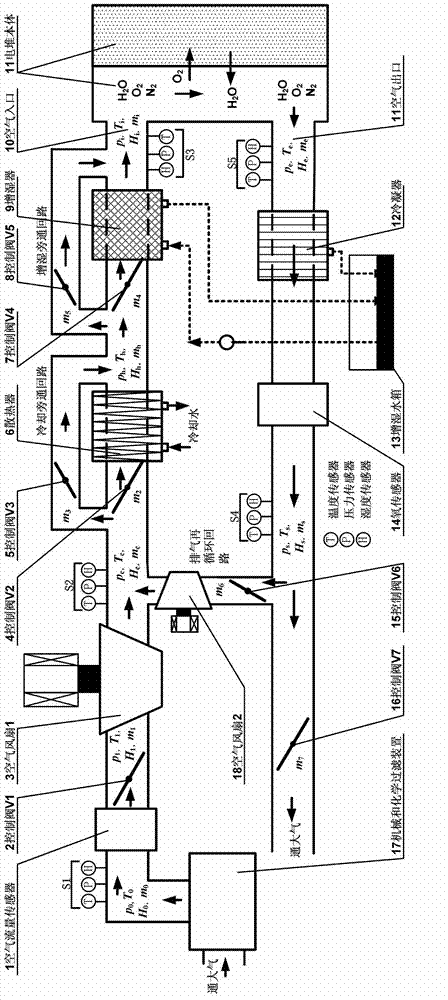

[0049] The two fuel cell air systems with exhaust gas recirculation of the present invention are respectively as attached figure 2 And attached image 3 As shown, its working characteristics are described below.

[0050] (1) Recirculation loop: use an exhaust recirculation loop to reintroduce the gas discharged from the cathode outlet of the stack to the inlet loop of the stack; according to the range of working pressure of the air system, there are two options to choose from; the first option as attached figure 2 As shown, for the scheme where the working pressure of component 11 (stack body) is relatively high (high-voltage stack, for example, the maximum working pressure of the stack is greater than 1.5bar), the recirculation circuit (including the pipeline and component 15 can be controlled Valve V6) is arranged before component 3 (air compressor); the second scheme is as attached image 3 As shown, for the scheme of component 11 (stack body) with low working pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com