Gas diffusion layer, proton exchange membrane fuel cell and power assembly

A gas diffusion layer and proton exchange membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as flooding reactions and unevenness, achieve optimal water distribution, broad application prospects, and alleviate the phenomenon of "flooding" Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

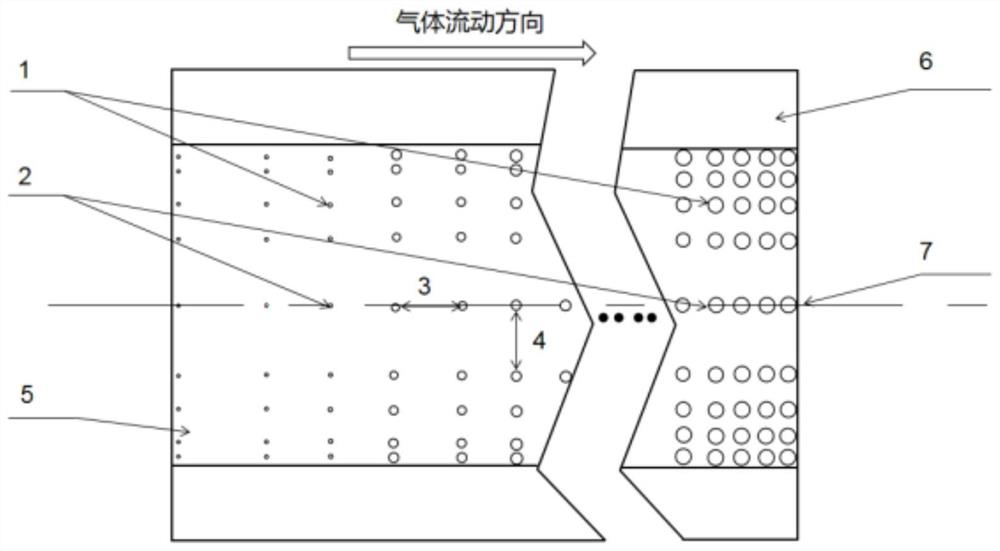

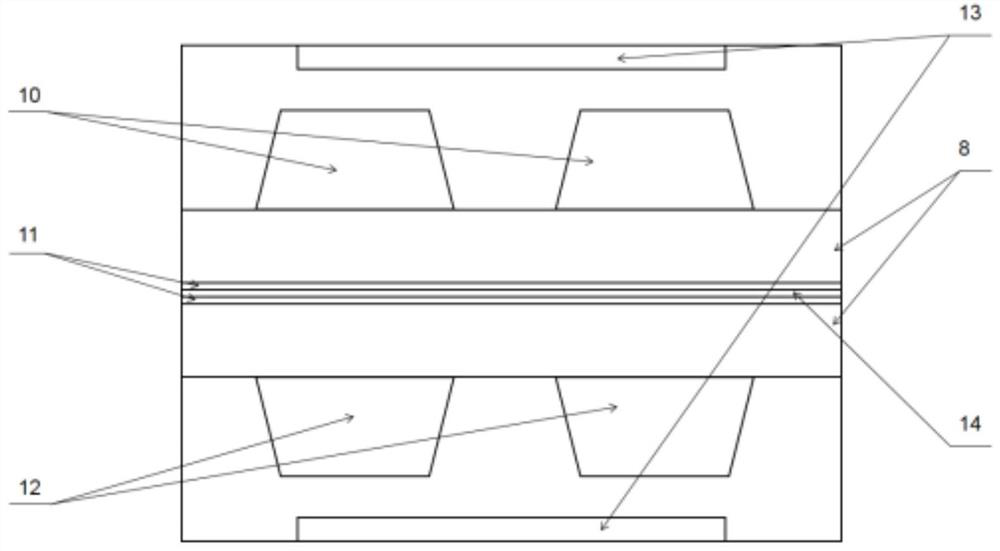

[0046] A gas diffusion layer for a proton exchange membrane fuel cell, comprising an anode diffusion layer and a cathode diffusion layer, the anode diffusion layer is close to the anode flow channel 12, and the cathode diffusion layer is close to the cathode flow channel 10;

[0047] The anode diffusion layer has a uniform pore structure;

[0048] The cathode diffusion layer has a variable pore structure, and the porosity of the pore structure increases gradually along the fluid flow direction;

[0049] And the part of the cathode diffusion layer corresponding to the position of the cathode flow channel 10 is provided with several through holes, and the diameter of the through holes increases gradually along the fluid flow direction.

[0050] The pore structure is made by a viscous mixture including carbon powder, isopropanol, lithium carbonate and polytetrafluoroethylene as a hydrophobic substance, and the viscous mixture is coated on the carbon paper according to the gradient ...

Embodiment 2

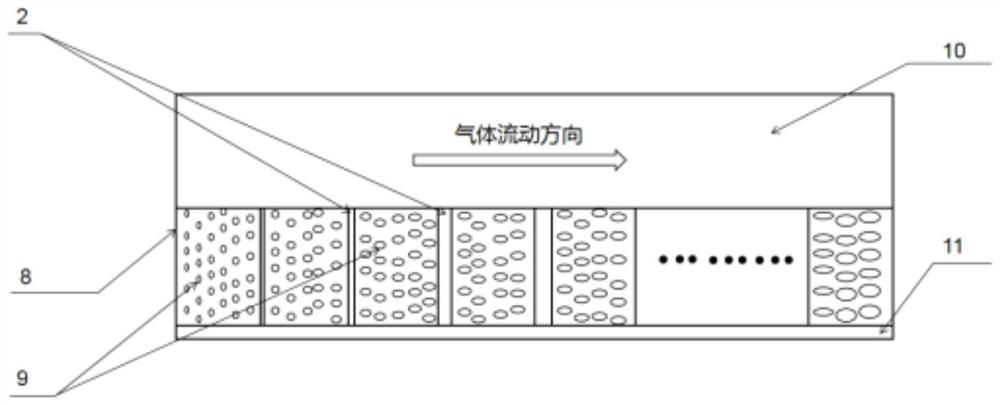

[0059] Proton exchange membrane fuel cell stacks, such as image 3 As shown, the cathode flow channel 10 and the anode flow channel 12 of the battery are respectively straight channels and bipolar plates with serpentine flow, a catalytic layer for enhancing the battery reaction, a proton exchange membrane for mass transfer and a gas diffusion layer .

[0060] The porosity of the gas diffusion layer conforms to the linear law, and the diffusion layer is vertically perforated according to the Peel growth curve and the Gompertz growth curve; in addition, the diffusion layer is treated with hydrophobicity, and the resistance and water resistance during gas transmission are improved by this method. Manage the situation to ensure the consistency of water distribution in the direction of gas flow.

[0061] In this embodiment, the total length of the proton exchange membrane fuel cell is L, the length ranges from 750 to 900 mm, the width is B, and the range is 500 to 650 mm, the thic...

Embodiment 3

[0082] A power assembly or power equipment includes the proton exchange membrane fuel cell of the second embodiment, such as construction machinery equipment such as trucks and tractors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com